¶ Introduction

The objective of this project is to integrate a working camera module into the Firehorn rocket to capture video and images during flight. The primary challenge lies in selecting and designing a camera system that can withstand the harsh environmental conditions encountered during flight while maintaining high-quality recording capabilities.

To achieve this, multiple factors were considered, including mechanical integration, electronic communication, thermal management, and compliance with the constraints imposed by the rocket’s structure and avionics system. The selected camera must be robust, lightweight, and capable of delivering high-quality footage throughout the flight duration.

¶ Requirements Needed

- 2024_C_SE_PL_CAMERAS_REQ_01 Declaration of purpose

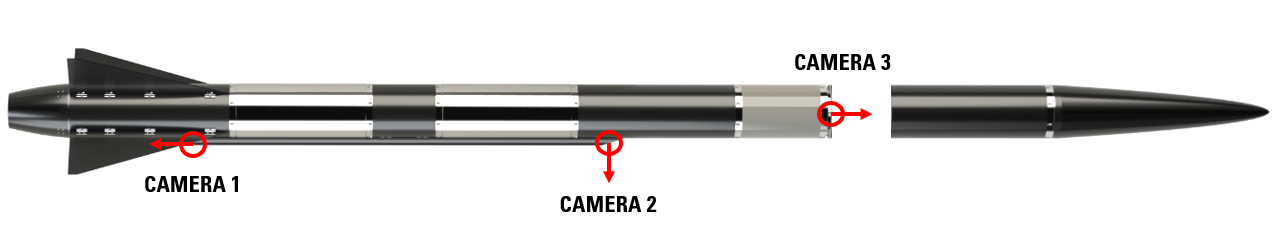

Cameras shall be integrated into the launch vehicle to record the flight. - 2024_C_SE_PL_CAMERAS_REQ_02 Camera locations 1

A camera shall be located at the bottom end of the aerocover to record downwards during flight. - 2024_C_SE_PL_CAMERAS_REQ_03 Camera location 2

A camera should be located at the top end of the aerocover to record upwards during flight. - 2024_C_SE_PL_CAMERAS_REQ_04 Camera location 3

A camera should be located at the top of the avionics bay to record the parachute deployment. - 2024_C_SE_PL_CAMERAS_REQ_05 Maximum mass

A single camera and all its components shall have a maximum mass of 250g. - 2024_C_SE_PL_CAMERAS_REQ_06 Filming module dimensions

The filming module of the camera shall have a maximum cross-sectional area of [25]mm x [25]mm. - 2024_C_SE_PL_CAMERAS_REQ_07 Avionics independency - control

The camera module should not rely on the avionics module to start and/or stop the recording. - 2024_C_SE_PL_CAMERAS_REQ_08 Avionics independency - power

The camera module shall not rely on the avionics module to be powered.

¶ Design Objectives

The camera module implementation requires addressing multiple design factors that will be tested before the Firehorn flight.

¶ Temperature Resistance

- The camera must endure extreme external, interface, and internal temperatures for at least 3 minutes.

- Camera-generated heat must be evaluated to determine whether a heat exchanger is required.

¶ Space and Avionics Allocation

- The camera module is housed within the "Dorsale" of the rocket, restricting space and weight.

- It must be compact and lightweight while ensuring safe data transmission under harsh conditions.

¶ Electronic Integration

¶ Camera Selection

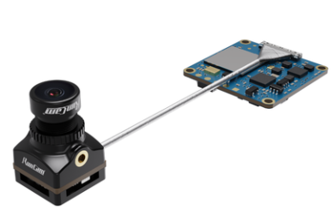

The RunCam Split 4 v2 was selected due to its compact size, high resolution, and lightweight build. This camera module is equipped with a separate processing board, which allows the lens to be positioned independently while minimizing weight constraints. The selection of this camera was based on the following criteria:

- Resolution and Frame Rate: 2.7K at 60 fps.

- Field of View: 140°.

- Communication Interface: UART.

- Power Consumption: 2.25 W.

- Weight: 10.2 g.

¶ Why not a Raspberry Pi Camera or a Full Custom Camera?

We opted for a RunCam because it provides significantly better resolution and performance than a Raspberry Pi camera while remaining within an acceptable budget. There was no particular need for a fully custom camera, as the RunCam met all the project’s requirements. Additionally, since the goal of the semester project was to have a functional camera system by the end of the semester, designing a full custom camera would have taken much longer and might not have resulted in a working product within the timeline. Furthermore, a custom design would not necessarily have provided any significant advantage over the RunCam.

¶ Could Other RunCam Models Work?

Other RunCam models could also be used. The RunCam Split 4v2 was chosen for its availability and performance, but the RunCam Split HD is another viable option, albeit slightly larger. Other RunCam models could also be considered, although some are optimized for FPV applications, which is not the primary goal of this project.

¶ Communication Protocol

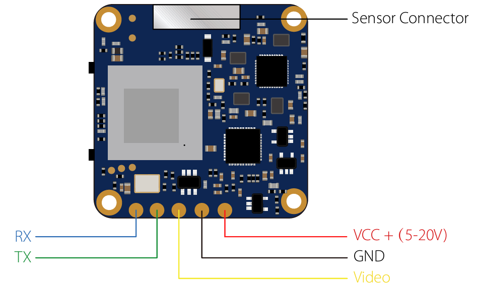

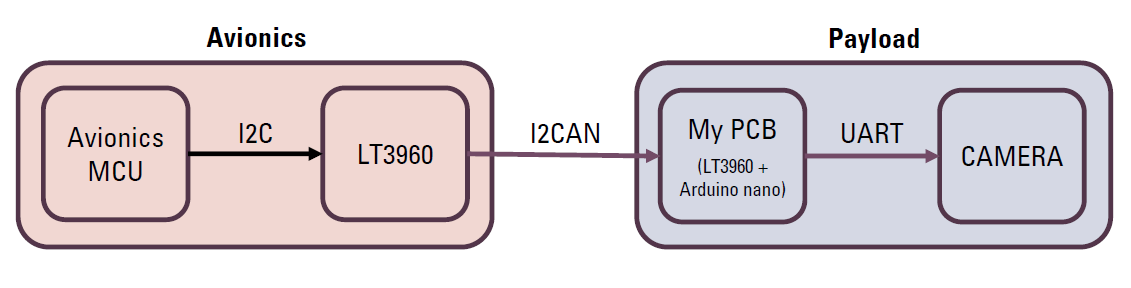

The avionics use I2C, while the camera communicates via UART, requiring protocol conversion:

- Avionics → LT3960 (I2C to I2CAN)

- LT3960 → Conversion PCB (I2CAN to UART)

- Conversion PCB → Camera (power and control)

¶ Why Do We Need an I2CAN -> UART Protocol Conversion?

All RunCam cameras communicate via UART, while our avionics module communicates via I2C, which is converted into an I2CAN bus for long-distance communication. The conversion is necessary to ensure proper compatibility between the two modules.

¶ PCB Design

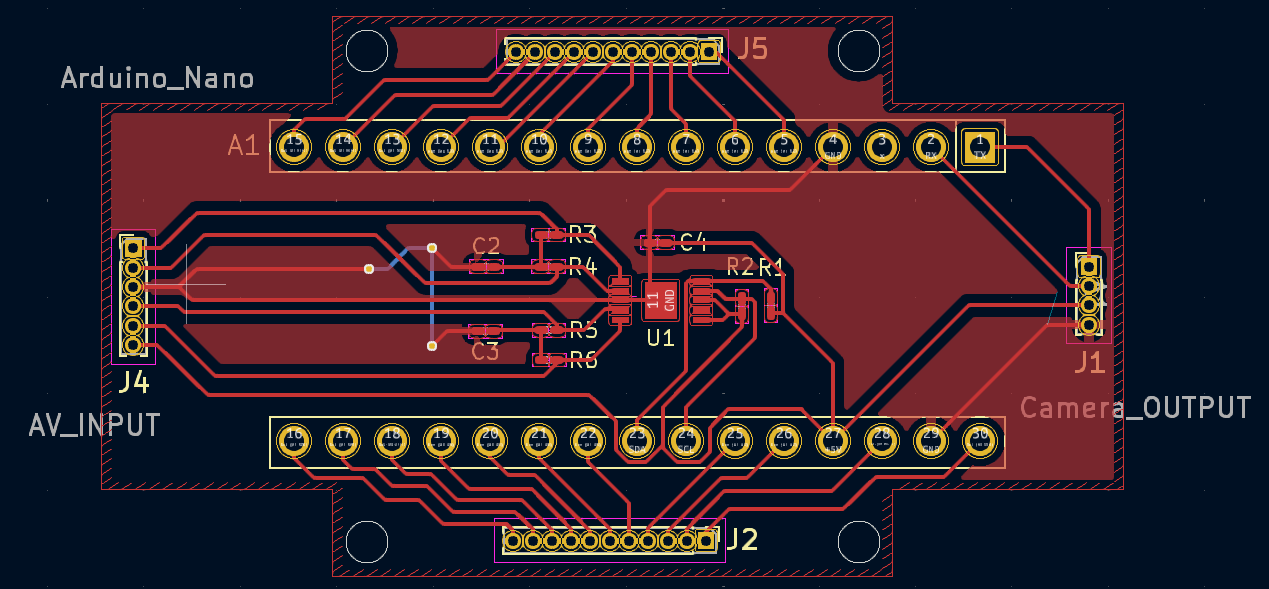

A custom PCB was designed to:

- Convert I2CAN to UART

- Regulate stable power to the camera

- Maintain compact modularity for avionics integration

¶ Why an Arduino Nano?

An Arduino Nano was chosen for communication conversion because it provides a simple and modular solution that can be easily adapted for future modifications. If changes are needed in the future, the Nano allows for quick reprogramming and adjustments.

¶ Mechanical Integration

The camera module is securely mounted using custom supports designed to fit within the aerocover structure.

¶ Camera Placement

- Camera 1: Bottom aerocover, facing downward (liftoff monitoring)

- Camera 2: Top aerocover, radial orientation (flight environment capture)

¶ Mechanical Supports

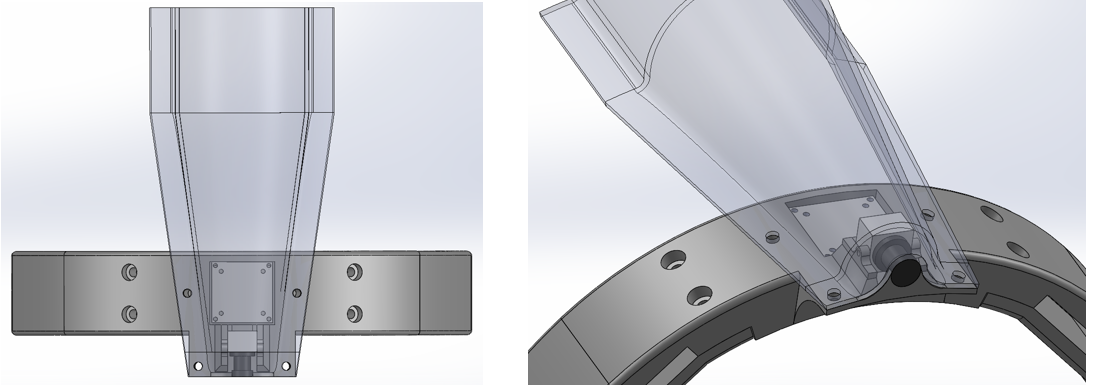

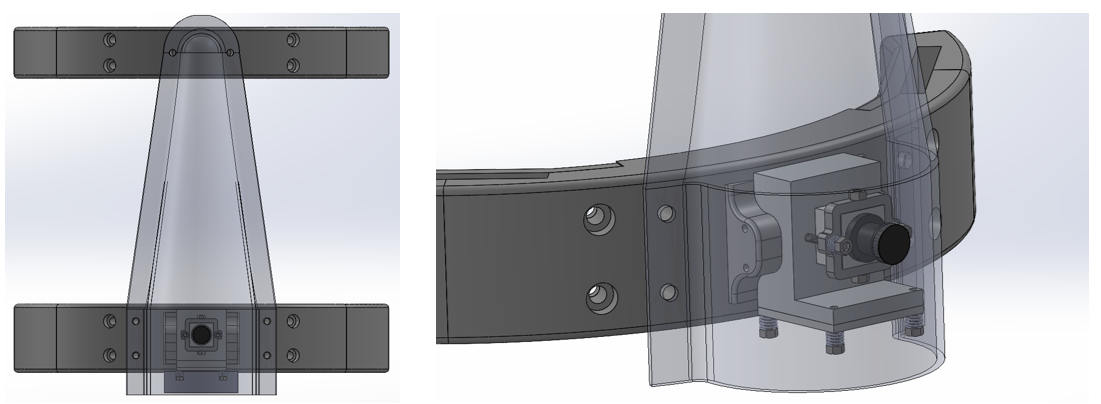

Camera 1 Support:

- Integrated into the aerocover

- Weight: 125.5 g

- Modified aerocover design to prevent obstruction

Camera 2 Support:

- Aluminum heat block for thermal management

- Spring-loaded screws to mitigate vibrations

- Weight: 221.66 g

¶ Thermal Testing

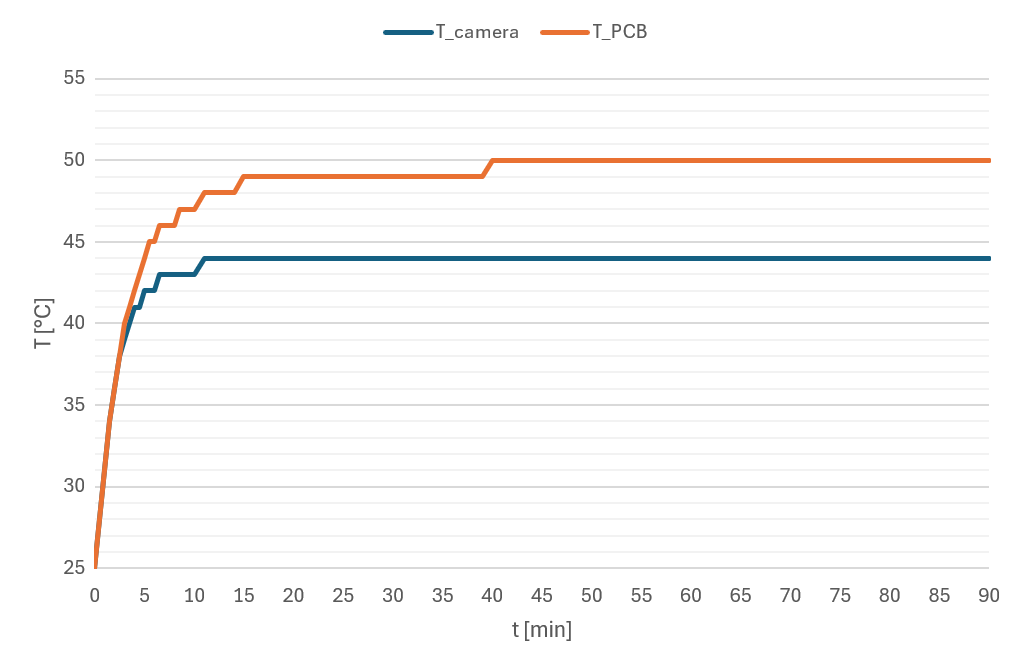

Due to the expected heat buildup within the fuselage, a thorough analysis was conducted to determine the camera’s temperature stabilization over time. The following graph illustrates the thermal behavior of the camera and PCB over a 90-minute test period:

From the test data:

- Standalone Camera stabilized at 44°C.

- Standalone PCB stabilized at 50°C.

- Camera + Aluminum Block stabilized at 36.07°C.

These results confirm the necessity of thermal dissipation techniques, such as the integration of an aluminum heat block to mitigate overheating.