¶ Introduction

This document serves as the Structure Design Justification File (DJF) for the Acoustic Levitator Assembly. It addresses both the internal and external components of the assembly. The primary objective of this assembly is to ensure a robust structural framework that supports the electronic and software configurations necessary for stable and controlled levitation of a small spherical object using ultrasonic transducers.

¶ Definitions and Abbreviations

- DJF: Design Justification File

- EuRoC: European Rocketry Challenge

- SE: Systems Engineering

- PL: Payload

- PETG: Polyethylene Terephthalate Glycol

- HT PETG: High-Temperature Polyethylene Terephthalate Glycol

- M5: Metric 5mm

- g: Acceleration due to gravity (9.81 m/s²)

- N: Newton

¶ Structure and Assembly - Requirements

The goal of this part of the project is to design and implement the payload for the acoustic levitation experiment that will be used in the Firethorn Rocket at the EuRoC 2025 competition.

The payload must ensure that it meets all specified requirements for dimensions, structure, and assembly operations to be compatible with the Payload Bay designed by the Structure team.

¶ Dimension Requirements

The payload must fit within the specified dimensions and meet the following criteria:

-

2024_C_SE_PL_ACOUSTIC_LEVITATION_EXPERIMENT_06

Mass

The payload mass shall be between [3000]g and [3990]g. -

2024_C_SE_PL_ACOUSTIC_LEVITATION_EXPERIMENT_07

Volume

The payload shall fit within a [30]x[10]x[10]cm volume.

¶ Structure Requirements

The payload must have its own structure and be able to withstand various loads and accelerations:

-

2024_C_SE_PL_ACOUSTIC_LEVITATION_EXPERIMENT_08

Structure

The payload shall include its own internal or external structure. -

2024_C_SE_PL_ACOUSTIC_LEVITATION_EXPERIMENT_09

Structure load case

The payload structure shall protect the experiment from axial accelerations loads of at least [60]g's. -

2024_C_SE_PL_ACOUSTIC_LEVITATION_EXPERIMENT_10

Structure load case

The payload structure shall protect the experiment from radial accelerations of at least [3]g. -

2024_C_SE_PL_ACOUSTIC_LEVITATION_EXPERIMENT_11

Restricted materials

The payload shan't contain any hazardous material such as lead or radioactive elements. -

2024_C_SE_PL_ACOUSTIC_LEVITATION_EXPERIMENT_12

Payload assembly

The payload structure shan't be inextricably connected to other rocket components than the payload supporting structure.

¶ Assembly and Operations Requirements

The payload needs the following properties when it comes to assembly and operations:

-

2024_C_SE_PL_ACOUSTIC_LEVITATION_EXPERIMENT_21

Assembly time

Assembly of the payload in the launch vehicle shan't take more time than [10]min. -

2024_C_SE_PL_ACOUSTIC_LEVITATION_EXPERIMENT_13

Assembly human needs

The assembly of the payload shall require at most [2] person. -

2024_C_SE_PL_ACOUSTIC_LEVITATION_EXPERIMENT_14

Operation human needs

The operation of the payload shall require no more than [1] person.

¶ Structure Overview

The external structure of the Acoustic Levitator Assembly prototype is constructed from laser-cut Plexiglas. This material is chosen for its ease of machining and transparency, which allows for visual inspection of the internal components. While Plexiglas is sufficient for prototyping, the final design may incorporate more rigid materials to improve structural integrity.

The internal structure is designed for modularity and ease of assembly. It features a 3D-printed base plate with inserts to secure M5 rods. These rods serve as the primary framework, allowing various components to be mounted and adjusted using M5 nuts. The key internal components include:

- Battery Pack Holder: Secures the battery pack, providing stable power to the system.

- Acoustic Levitator: The core component for levitation, mounted on the rods for stability.

- Stabilizer: Ensures the two halves of the acoustic levitator are maintained at an 8.5 cm distance.

- Raspberry Pi Zero W Holder: Houses the Raspberry Pi Zero W, the main processing unit.

- Accelerometer Holder: Secures the accelerometer, for monitoring and recording data during levitation.

- Camera Holder: Positioned to monitor the levitation process, ensuring clear visual data.

Each of these components is designed to fit onto the M5 rods, providing a flexible and robust internal structure that can be easily assembled and adjusted. The design ensures that all parts are securely held in place, allowing for precise and reliable operation of the Acoustic Levitator Assembly.

¶ Design Choices: External Structure

¶ Overview

The external structure of the Acoustic Levitator Assembly is designed to provide a robust framework that houses and protects the internal components. For the prototype, we are using Plexiglas due to its ease of laser cutting and adequate structural properties. In the final design, we may choose a more rigid material to improve durability and performance.

¶ Features

| Feature | Description |

|---|---|

| Material | Plexiglas (for the prototype) |

| Construction Method | Laser cutting |

| Dimensions | 30x10x10 cm volume |

| Weight | Approximately 700g |

¶ Components

- Base Plate: A 3D printed base plate made of PETG, which includes inserts to secure the M5 rods.

- M5 Rods: These rods provide a stable framework for mounting various internal components. The rods are fixed into the base plate and secured with M5 nuts.

- Internal Components: The battery pack holder, acoustic levitator, stabilizer between the two spheres of the levitator, Raspberry Pi holder, accelerometer holder, and camera holder are all mounted on these rods.

- Protective Shell: The Plexiglas shell encloses the entire assembly, providing protection from external forces and environmental factors.

¶ Future Considerations

- Material Upgrade: For the final design, we may explore using more rigid materials such as aluminum or reinforced composites to improve the durability and structural integrity of the external shell.

- Vibration Dampening: Incorporating foam or other dampening materials around the M5 rods to mitigate vibrations that could affect the experiment's accuracy and stability.

¶ Design Choices: Internal Structure

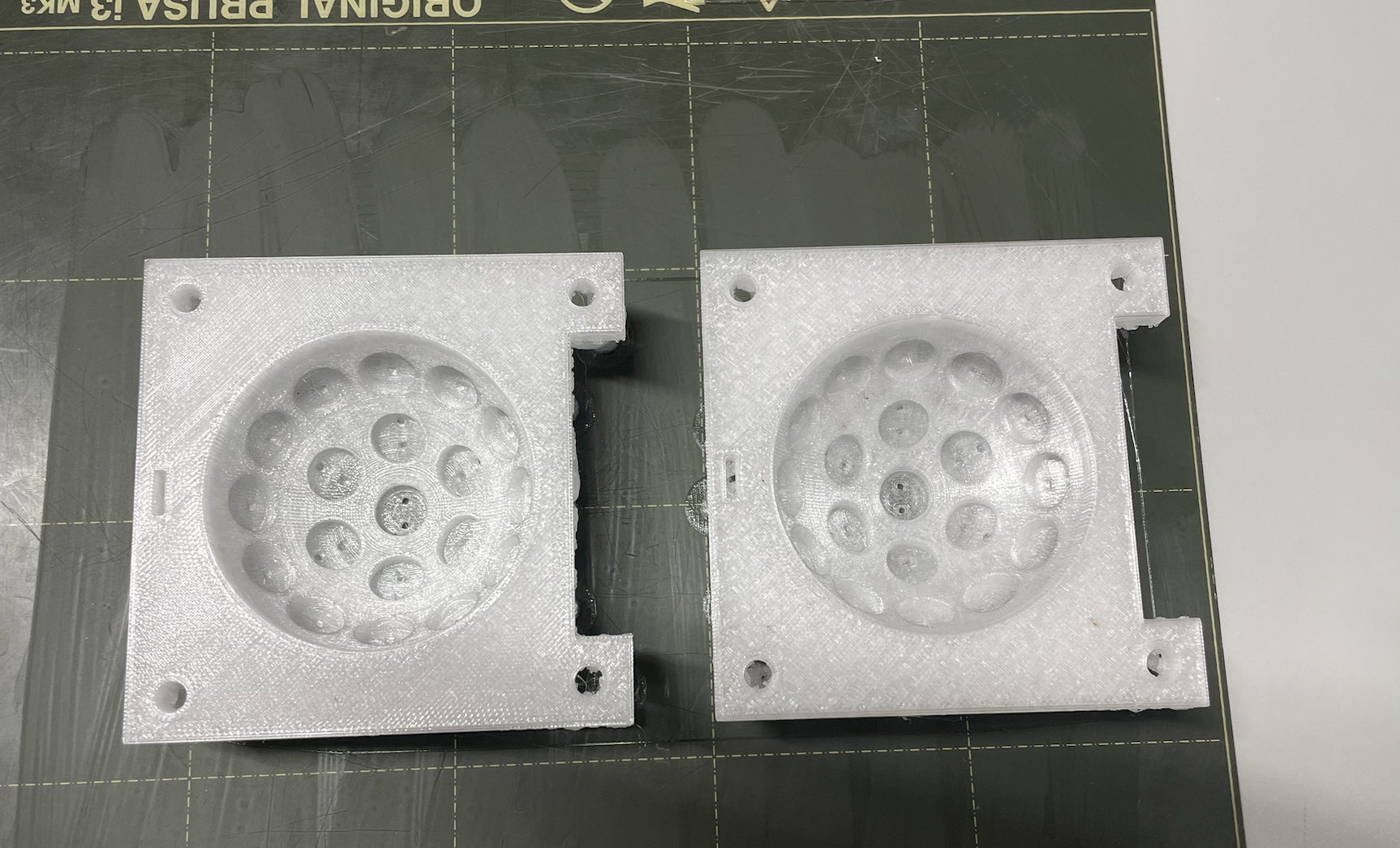

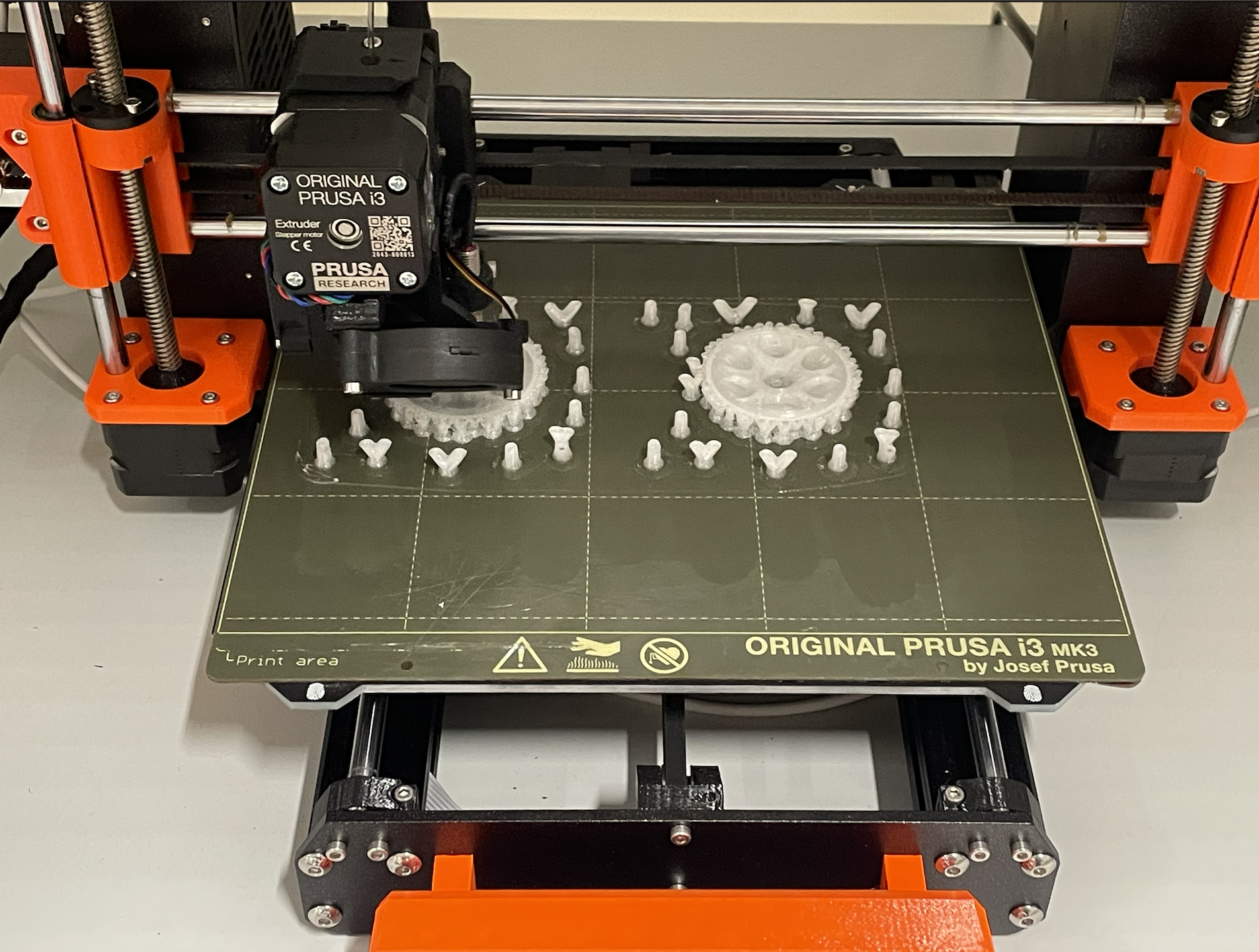

¶ Design of the Acoustic Levitator

- Initial Material: The first version of the acoustic levitator was constructed using regular PETG. PETG was selected for its ease of printing and adequate structural properties.

- Problem Encountered: During the assembly, particularly when soldering components onto the structure, regular PETG showed a significant weakness: it was not resistant to the heat introduced during soldering, leading to deformation and structural integrity issues.

- Material Upgrade: To overcome the heat resistance issue, the levitator structure was redesigned using High-Temperature PETG. This material maintains the benefits of standard PETG but can withstand higher temperatures without deforming, making it ideal for processes involving heat.

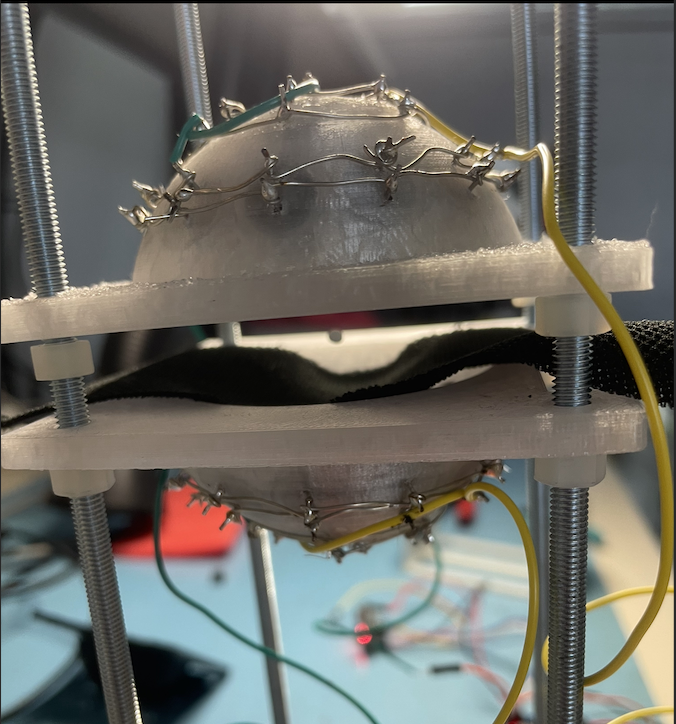

- Initial Idea: Originally, the design included a mechanism where the particle was to be attached to a thin string, as this would allow the particle to be positioned accurately below the node of the acoustic field before activation.

- Challenge with Initial Idea: The practical implementation of threading a string through a very small particle proved to be unfeasible and complex, especially given the minuscule size of the particle.

- Innovative Solution: The final design incorporated a sonic permeable sheet, similar in concept to the material used in loudspeaker covers. This sheet allows sound waves to pass through while providing a non-intrusive support to hold the particle in place.

- Implementation and Results: The sheet is positioned so that it holds the particle just below the levitation node pre-activation. When the levitator is activated, the particle dislodges from the sheet and rises to the node, effectively beginning the levitation. Testing confirmed that the sheet does not negatively impact the acoustic field or the levitation process.

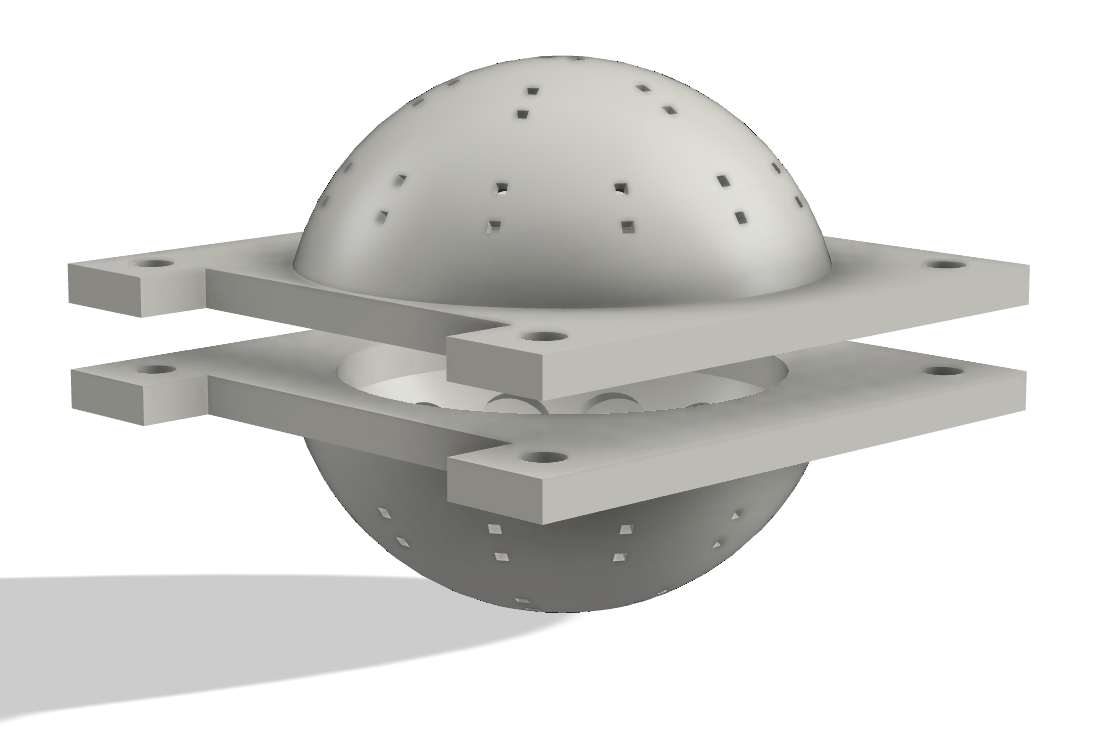

The acoustic levitator is designed for practical application and ease of use, incorporating several key features to facilitate its operation and integration within experimental setups:

- Mounting Mechanism: The levitator is constructed to mount directly onto four rods, ensuring a stable and secure setup. It utilizes M5 nuts for fastening, providing a robust connection that can withstand the operational vibrations and movements inherent to acoustic levitation.

- Camera Access: A strategically placed small opening in the front of the device allows for the insertion of a camera. This opening is designed to accommodate the camera module without compromising the structural integrity of the levitator, enabling real-time monitoring of the levitation process.

- Wire Management: To address the need for electrical connectivity, there is a small opening in the back of the levitator. This feature facilitates the neat and organized routing of wires, ensuring that connections are both accessible and protected from any mechanical interference.

| Feature | Description |

|---|---|

| Material | High-Temperature PETG |

| Construction Method | 3D Printing |

| Dimensions | 85 x 85 x 70 mm |

| Weight | 55g |

¶ Other internal components

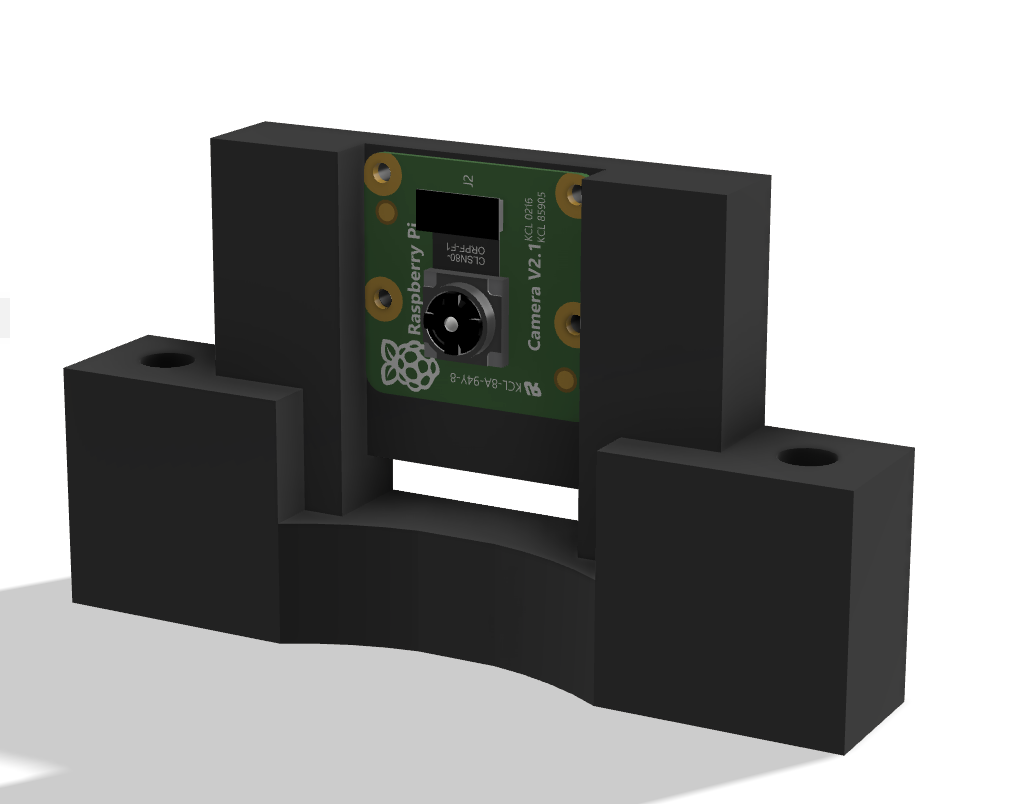

The camera holder in the acoustic levitator is engineered to ensure stability, accessibility, and good camera positioning for monitoring the levitation process:

- Mounting and Stability: The camera holder is designed to mount directly onto the four rods that form the framework of the levitator. It uses M5 nuts to ensure a stable attachment.

- Accessibility for Connections: A small opening in the back of the holder is provided to facilitate easy introduction and management of camera connections.

- Optimal Camera Positioning: The holder positions the camera at a distance of 30cm from the levitating particle. This placement is optimized to fall within the camera's depth of field, which ranges from 10 cm to infinity, ensuring clear and focused images of the particle throughout the experiment.

¶ Features

| Feature | Description |

|---|---|

| Material | PETG |

| Construction Method | 3D Printing |

| Dimensions | 85 x 15 x 50 mm |

| Weight | 30g (Holder) + 10g (Camera) |

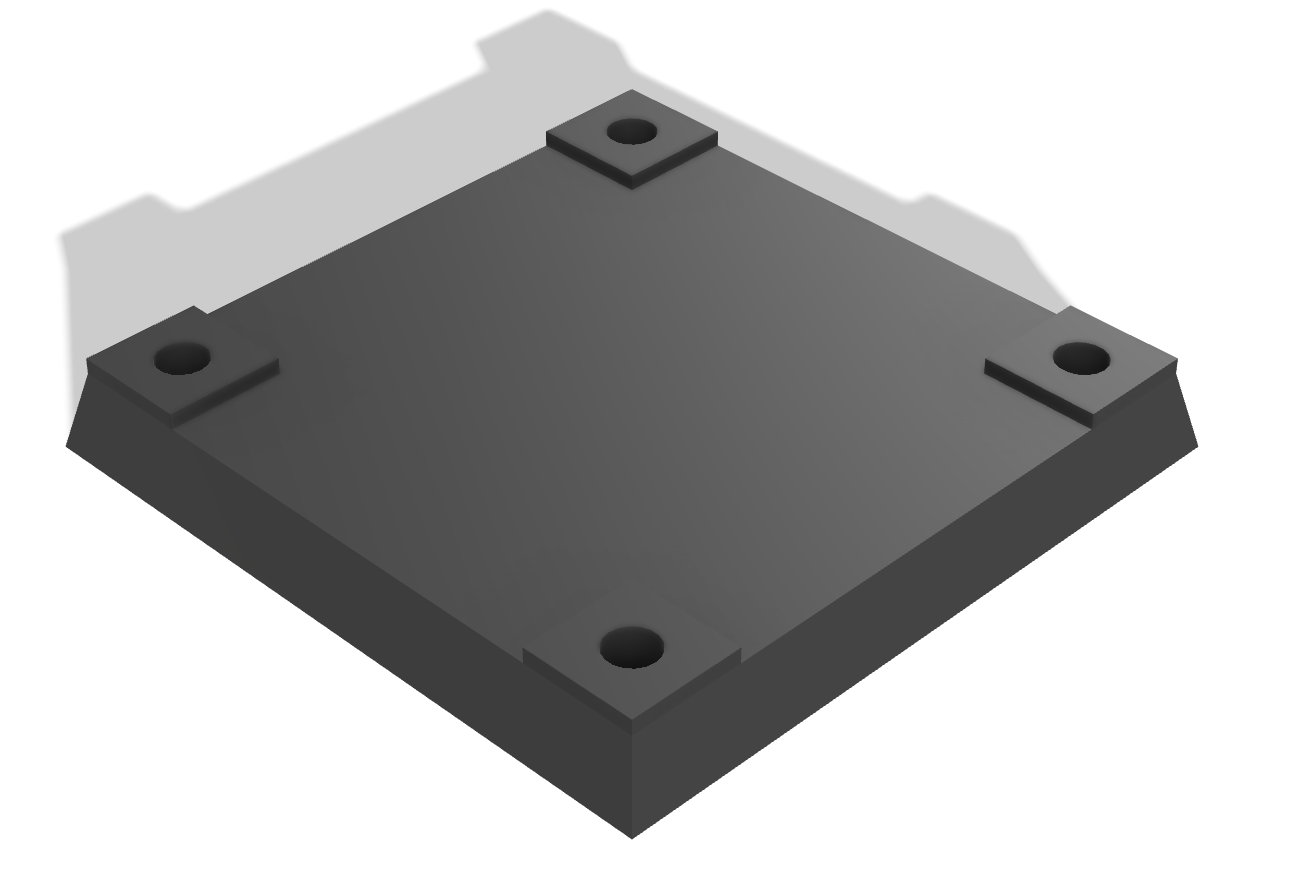

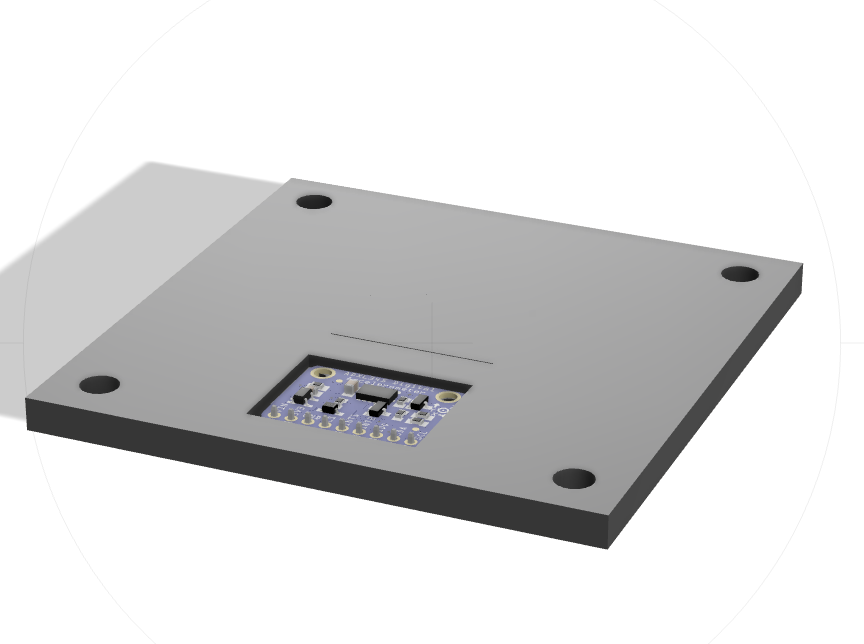

The stabilizing plate serves as the foundational component for the internal structure of the Acoustic Levitator Assembly. It is designed to securely hold the M5 rods, providing a stable framework for mounting various components. This plate ensures that all internal parts remain securely positioned during the levitation process.

¶ Features

| Feature | Description |

|---|---|

| Material | PETG |

| Weight | 35g |

| Dimensions | 85 x 85 x 10 mm |

| Function | Securely holds M5 rods, which support other components of the internal structure |

The battery pack holder is designed to securely hold the battery pack and integrate additional components such as switches, LEDs, and buzzers. This holder is necessary for maintaining the power supply's stability and ensuring that all connected devices function correctly.

¶ Features

| Feature | Description |

|---|---|

| Material | PETG |

| Weight | 70g + 100g (batteries) |

| Dimensions | 35 x 94 x 85 mm |

| Function | Holds the battery pack and integrates additional components for power management |

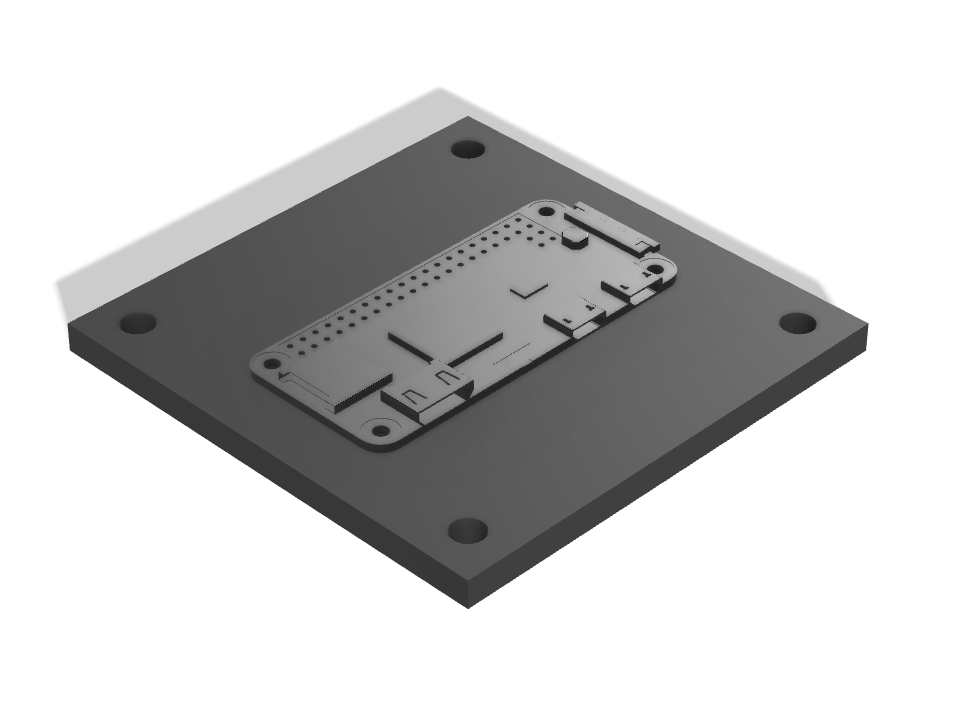

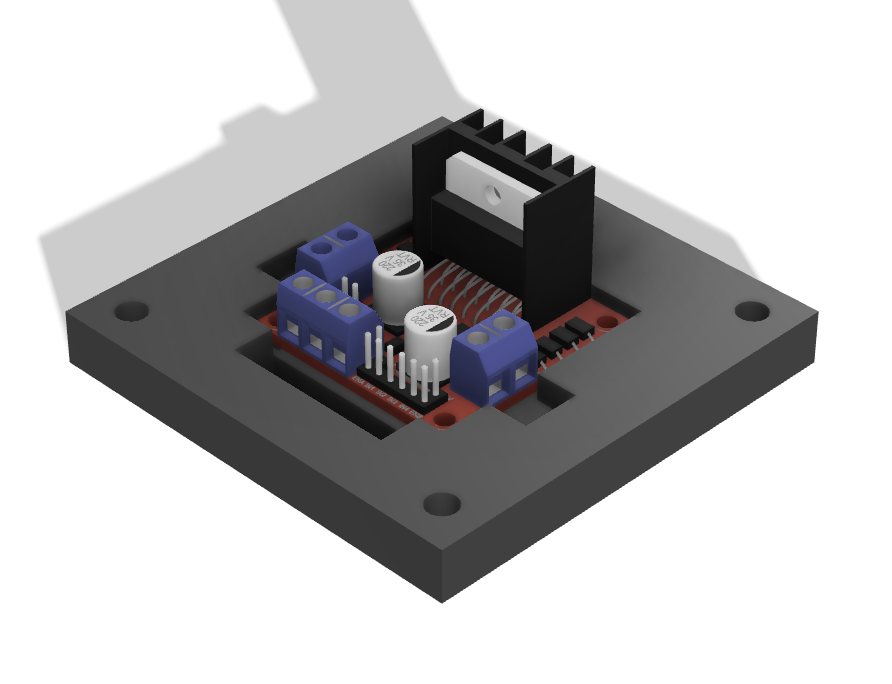

These holders are designed to secure various electronic components such as the Raspberry Pi, motor driver, and accelerometer. In the prototype, these components are individually mounted, but the final design will likely integrate them into a single PCB to simplify the assembly and improve reliability.

¶ Raspberry Pi Holder

| Feature | Description |

|---|---|

| Material | PETG |

| Weight | 10g (Raspberry Pi) + 21.5g (RPH) |

| Dimensions | 85 x 85 x 5 mm |

| Function | Secures the Raspberry Pi, ensuring stable operation and connectivity |

¶ Motor Driver Holder

| Feature | Description |

|---|---|

| Material | PETG |

| Weight | 35g (motor driver) + 28g (MDH) |

| Dimensions | 85 x 85 x 10 mm |

| Function | Secures the motor driver, providing stable power amplification for the transducers |

¶ Accelerometer Holder

| Feature | Description |

|---|---|

| Material | PETG |

| Weight | 10g + 5g (accelerometer) |

| Dimensions | 85 x 85 x 5 mm |

| Function | Secures the accelerometer, ensuring accurate monitoring of the system's movements and vibrations |

¶ Static Loads

¶ Overview

To ensure the structural integrity of the Acoustic Levitator Assembly under extreme conditions, we conducted simulations applying a 60g acceleration to various components. These simulations help us understand how the structure will react under high-stress conditions, necessary for ensuring the reliability and safety of the payload during the rocket's flight.

¶ Results

- Displacement Analysis: The simulations showed very small displacements, with a maximum of about 0.02 mm. This indicates that the structure can withstand the applied loads without significant deformation.

¶ Assembly

¶ Overview

The fully assembled payload integrates all components into a cohesive structure that fits within the specified dimensions. The battery needs to be connected to both the motor driver and the Raspberry Pi, situated between the two for efficient space utilization and stability.

¶ Features

- Material: Plexiglas (external structure), PETG (internal components)

- Weight: As specified per component

- Dimensions: Fits within the 30x10x10 cm volume constraint

¶ Steps

- Mount the M5 rods: Secure the M5 rods into the stabilizing plate.

- Attach components: Using M5 nuts, mount the battery pack holder, acoustic levitator, stabilizer, Raspberry Pi holder, motor driver holder, and accelerometer holder onto the rods.

- Connect electronics: Ensure all electronic components are correctly connected, with wires managed through designated openings.

- Finalize assembly: Secure the Plexiglas external structure, ensuring all components are firmly in place and protected.

¶ Possible Upgrades

- Vibration Mitigation: Consider adding foam around the rods to dissipate vibrations that could impact the experiment.

- Integrated PCB: In the final design, consolidate all electronic components onto a single PCB to streamline assembly and improve reliability.

¶ Payload Weight Estimation

The following table provides a detailed breakdown of the weight of each component in the Acoustic Levitator Assembly. This estimation ensures that the total payload weight is within the specified requirements.

| Component | Weight (g) |

|---|---|

| External Structure | 700 |

| Acoustic Levitator | 55 |

| Camera Holder | 30 |

| Camera | 10 |

| Stabilizing Plate | 35 |

| Battery Pack Holder | 70 |

| Batteries (2x 18650) | 100 |

| Raspberry Pi Zero W | 10 |

| Raspberry Pi Holder | 21.5 |

| Motor Driver (L298N) | 35 |

| Motor Driver Holder | 28 |

| Accelerometer | 10 |

| Accelerometer Holder | 5 |

| M5 Rods (4x 30 cm) | 320 |

| Other (bolts, inserts, screws, etc.) | 100 |

Total Weight: 1,529.5 g

We will be able to add mass in order to reach the requirements.

¶ Payload Cost Estimation

The following table provides a detailed breakdown of the cost of each component in the Acoustic Levitator Assembly. Note that the costs for electronics represent an upper cap, as the actual cost could be lower. Additionally, a budget for testing and experimentation has been included.

| Component | Cost [CHF] | Contingency [%] | Cost with Contingency [CHF] |

|---|---|---|---|

| External Structure | 20 | 10 | 22 |

| Internal Structure | 80 | 10 | 88 |

| Electronics (Device) | 125 | 10 | 137.5 |

| Testing and Experimentation | 150 | 10 | 165 |

| Total | 375 | - | 412.5 |

| Margins (required) | - | - | 187.5 |

- External Structure: The cost is estimated to be around 20 CHF, covering the materials used for the Plexiglas construction.

- Internal Structure: The cost is approximately 80 CHF, which includes the cost of PETG for the internal components.

- Electronics (Device): The electronics cost is estimated at 125 CHF. This includes the cost of the Raspberry Pi Zero W, motor driver, accelerometer, camera, and other necessary electronics.

- Testing and Experimentation: A budget of 150 CHF has been allocated for testing and experimentation to ensure the functionality and reliability of the Acoustic Levitator Assembly.

The contingency percentage is set at 10% for all components to account for any unforeseen expenses or adjustments during the project. The total cost, including the contingency, amounts to 412.5 CHF, leaving a margin of 187.5 CHF within the total budget of 600 CHF.