¶ Introduction

This project's goal is gather as much useful information as possible on the structural integrity of the rocket Firehorn.

Different means will be discussed and the precise goal of each components for an efficient use of mass, money to achieve the best results

¶ Motivation

One of the main motivations for this project is to better understand the behaviour of EPFL Rocket Team's rockets and see how the reality compares to our simulation and expectations, which we hope they match.

Resonance frequency

This is in fine, what we want to find out about the rocket.

¶ Requirements Needed

- 2024_C_SE_PL_STRUCTURAL_SENSORS_REQ_01 Declaration of purpose

Structural sensors shall be integrated inside the launch vehicle to record the time history of loads encountered during flight. - 2024_C_SE_PL_STRUCTURAL_SENSORS_REQ_02 Integration location

The sensors shall be located in a location where they are able to record the loads encountered by the internal structure of the launch vehicle. - 2024_C_SE_PL_STRUCTURAL_SENSORS_REQ_03 Integration location 2

The sensors shall be located in a location where they are not interfering with the operations or the assembly/disassembly of other components of the launch vehicle. - 2024_C_SE_PL_STRUCTURAL_SENSORS_REQ_04 Maximum mass

The sensor module and all its components shall have a maximum mass of [250]g. - 2024_C_SE_PL_STRUCTURAL_SENSORS_REQ_05 Avionics independency - control

The sensors should not rely on the avionics module to start and/or stop the recording of data. - 2024_C_SE_PL_STRUCTURAL_SENSORS_REQ_06 Avionics independecy - power

The sensors shall not rely on the avionics module to be powered. - 2024_C_SE_PL_STRUCTURAL_SENSORS_REQ_07 Data storage

All data gathered by the sensors shall be stored in a 'black box' designed by AV. - 2024_C_SE_PL_STRUCTURAL_SENSORS_REQ_08 Filming duration

The sensors shall record the loads during the entire flight duration, from ignition to touchdown.

¶ Design Options

Different options are available on the market who's main goal is to measure structure's constraints in some way, that be measuring a deformation (e.g. strain gauges), measure an acceleration (e.g. MEMS accelerators) or measure a current (e.g. piezoelectric sensors).

And the different informations we want to collect must tell us, depending on the part being analysed the resonence frequency, the bending effort and compression stress.

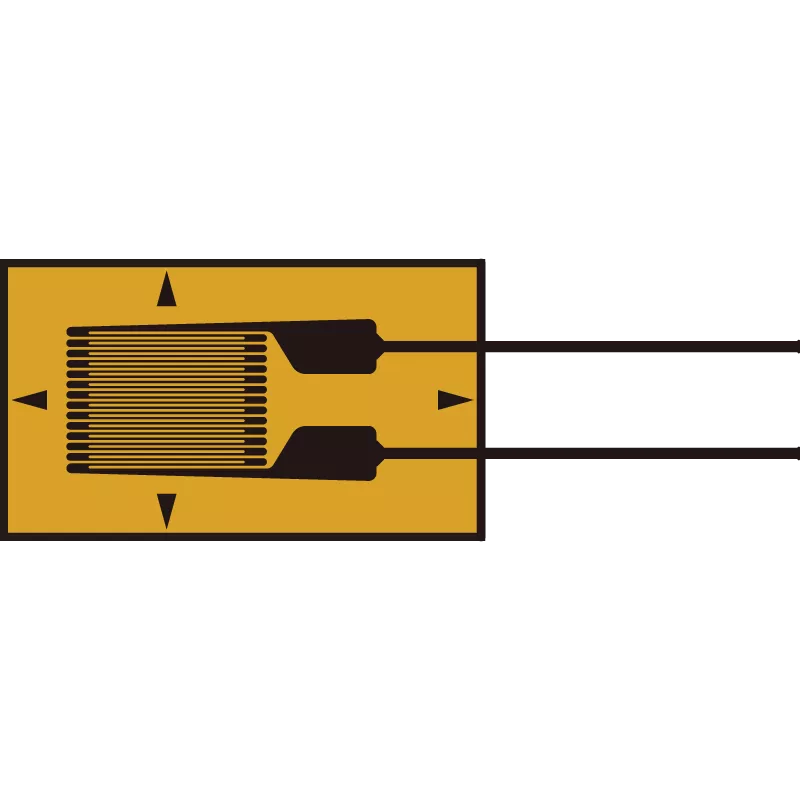

The first option is a strain gauge that works by deformation of the structure, which leads to the circuit being streched which in turns increases the resistance, and this resistance can be measured to obtain the value of deformation and constraint on the given structure.

Very light, Cheap, A lot of information can be found online

Only glued to the part

These sensors work on the principle of piezoelectric materials : an electrical (resp. mechanical) input results in a mechanical (resp. electrical) response.

This principle can thus be used to garther information on resonence frequence and on bending stress.

Thanks to the effort of a previous ERT member, a lot of work has already been done on this option, however it was unsuccessful and our analyis would be based on improving the previous work and try to make it more reliable and resilient.

Main Advantages: solid assembly, already been done

Main Disadvantages: takes more time to assemble, heavier, more expensive and lower chances of success

for the following option :

- Micro Electro-Mechanical Systems accelerator

- Capacitive displacement sensors

- Micro Electro-Mechanical Systems gyroscope

no further analysis has been dones as we were unable to find small enough sensors and the mass they would occupy made them unusable in our effort to collect information at low mass/money cost.

¶ Narrowing the Design Options

In the end, the selected project is the one using Strain Gauges.

Strain gauges offer the easiest gather of data and the amount of scientific articles found on these sensors give us a fair amount of information to pursue this project. Furthermore, they present the advantage of being reliable and not as sensible as Piezoelectric sensors to set our zero. However, this last point makes strain gauges less practical as they will gather data less thouroughly and slower.

¶ Adopted design

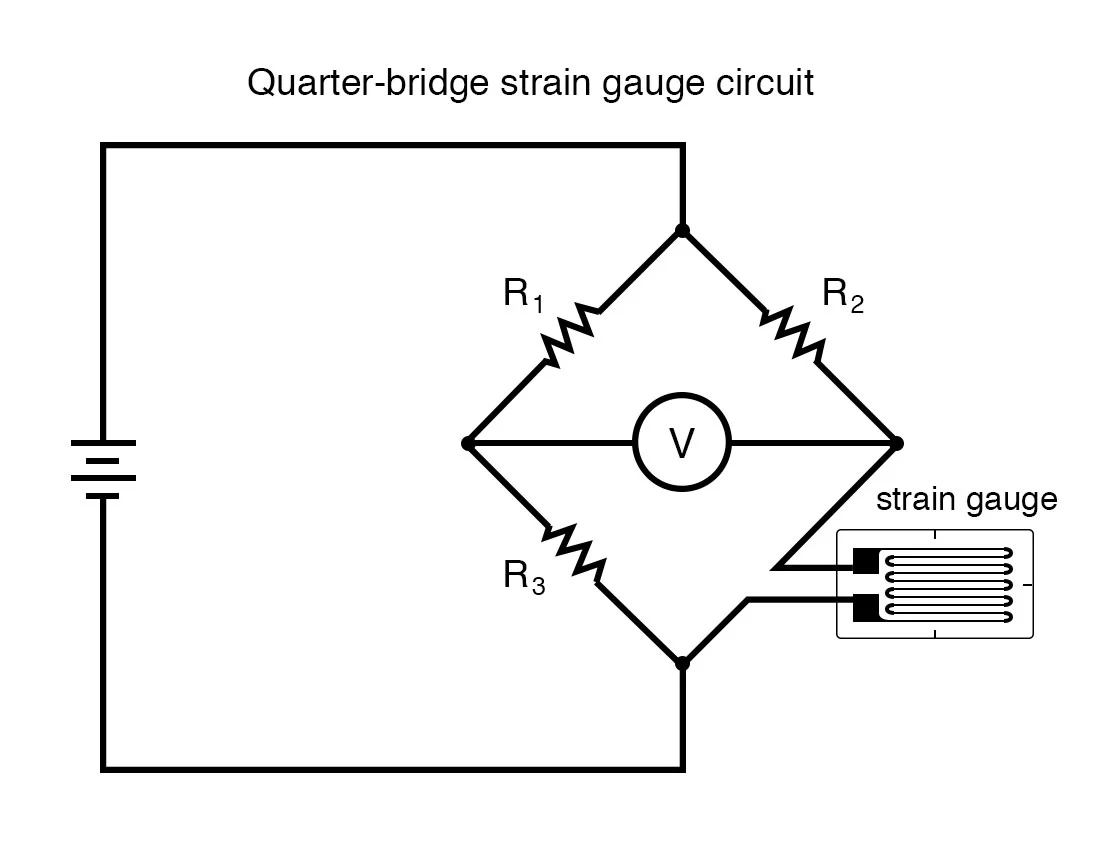

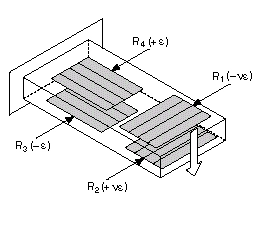

This is a common type of circuit used using a strain gauges and that allows the gathering of data from strains on the strain gauge, leading to a difference in voltage which can be measured via a voltmeter.

A fair amount of research went into finding the best circuit and then making it work, the later steps will be to implement this into a "module" which can be placed with ease on the rocket's structure, having enough batteryy for the whole wait-time and flight, and lastly, prevent current from reaching the rocket (due to its conductivity).

¶ Structure

The structure of this project shall be made such that the Quarter-bridge circuit, a power source and a "balck-box" be included in a "module" which can be placed, "glued" on the surface of the rocket's internal structure.

further research should give the PL team a better idea of how it will end up look like

¶ Conclusion

The success of this project shall provide the EPFL Rocket Team with a reusable module that can be use for future rockets and have access to new data in the scope of analysing ultra-sonic and outer-space stress/strain behaviour.