¶ Goal(s) of the study

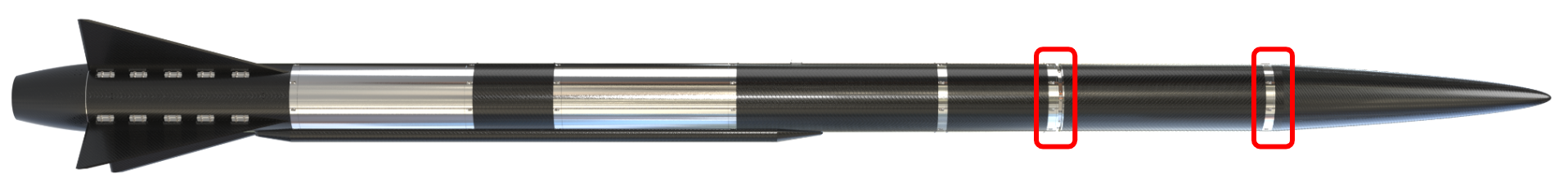

This document aims to present the method used to analyse with finite elements software the glued male coupler of the Firehorn rocket. Indeed, it is subjected to important loads during the flight, especially at the opening of the parachute.

¶ 214202_coupler_male_glued

¶ Geometry

The couplers are made of only one part, manufactured in 2050-T84 aluminum alloy. Below is an image of the glued male coupler.

¶ Function

The glued male coupler’s function is to link the nosecone to the recovery bay and the recovery bay to the separation mechanism. It shall resist the different forces applied to the structure, especially at the deployment of the parachute. The 2 glued male couplers are found at the bottom of the nosecone (1) and at the bottom of the recovery bay (1).

¶ Material

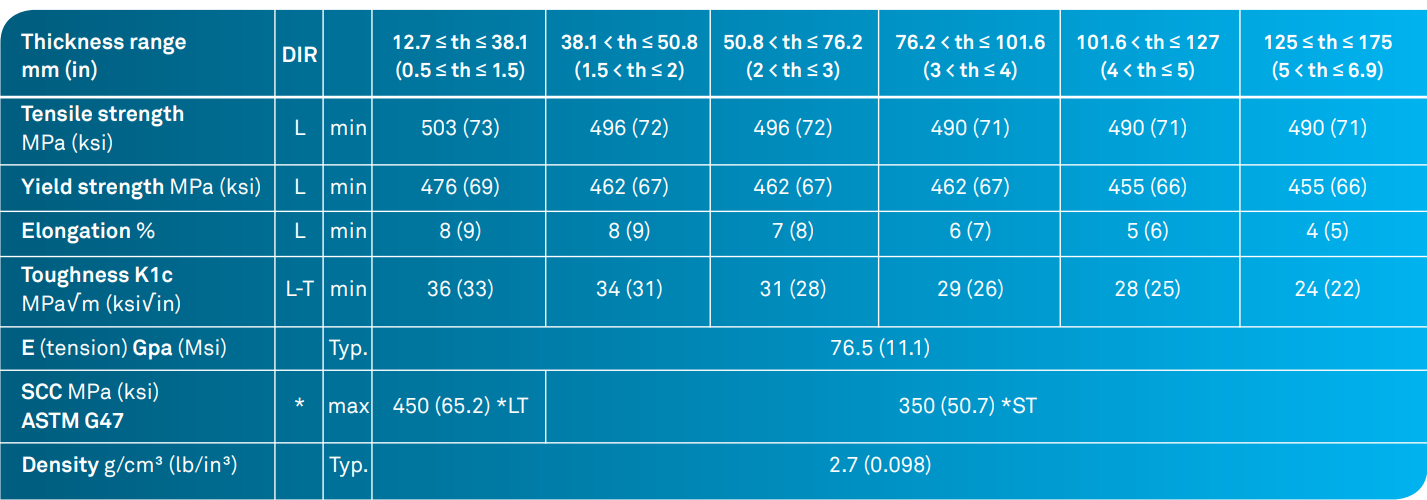

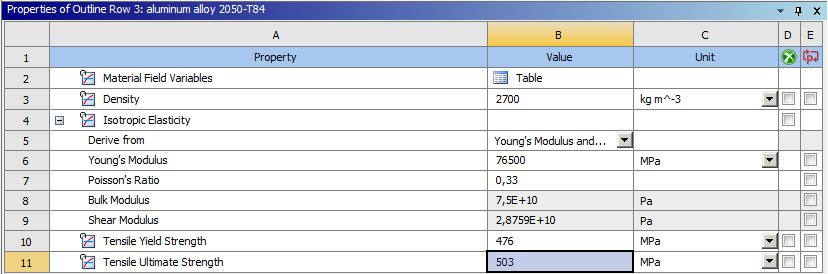

The coupler is machined in 2050-T84 aluminum alloy. This alloy has the following properties:

¶ Load case

Being part of the nosecone of the LV, the most important load the coupler will have to support is the tension due to the deployment of the parachute which corresponds to a 30g acceleration. According to the following requirement, this corresponds to an axial force of 4800 N. However this is the load case for FH 9, the load case for FH 30 is given by the following formula :

The 13.2 kg being the total mass that the coupler must absorb which includes its own weight, the female coupler, the shockplate, the payload, and the nosecone.

As a coupler the part shall also withstand an bending moment of 7500 Nm and a compressive force of 15000 N.

- 2024_C_SE_ST_NOSECONE_REQ_10 Nosecone load case - Deceleration

The structural elements in the nosecone shall withstand axial tensile loads of [4800]N. - 2024_C_SE_ST_RECOVERY-BAY_REQ_13 Upper shockplate load case

The structural elements in the recovery bay of the FH I LV shall withstand [4800]N of axial tensile loads. - 2024_C_SE_ST_COUPLER_REQ_21 Coupler load case - bending

The Coupler shall withstand [7500]Nm of bending moment. - 2024_C_SE_ST_COUPLER_REQ_20 Coupler load case - compression

The Coupler shall withstand [15000]N of compression loads.

¶ Finite Element Analysis

¶ Software

This FEA analysis was performed with the ANSYS Mechanical software for a static structural analysis. The CAD of the part was designed using Solidworks.

¶ Type of simulation

The simulations performed were static structural analysis to estimate the Von mises constraints for the load cases of a force of 7770 N in tension, 15000 N in compression and a bending moment of 7500 Nm.

¶ Inputs

The set of units used for this simulation is: mm, t, N, s, mA, mV.

The couplers are manufactured in 2050-T84 aluminum alloy. We used only the isotropic material properties, where we know the Young's modulus, the poisson ratio, the density, the Yield strength and the tensile strength. The following image shows the material properties implemented in the software.

Time was not taken into account for this simulation.

¶ Tension load case

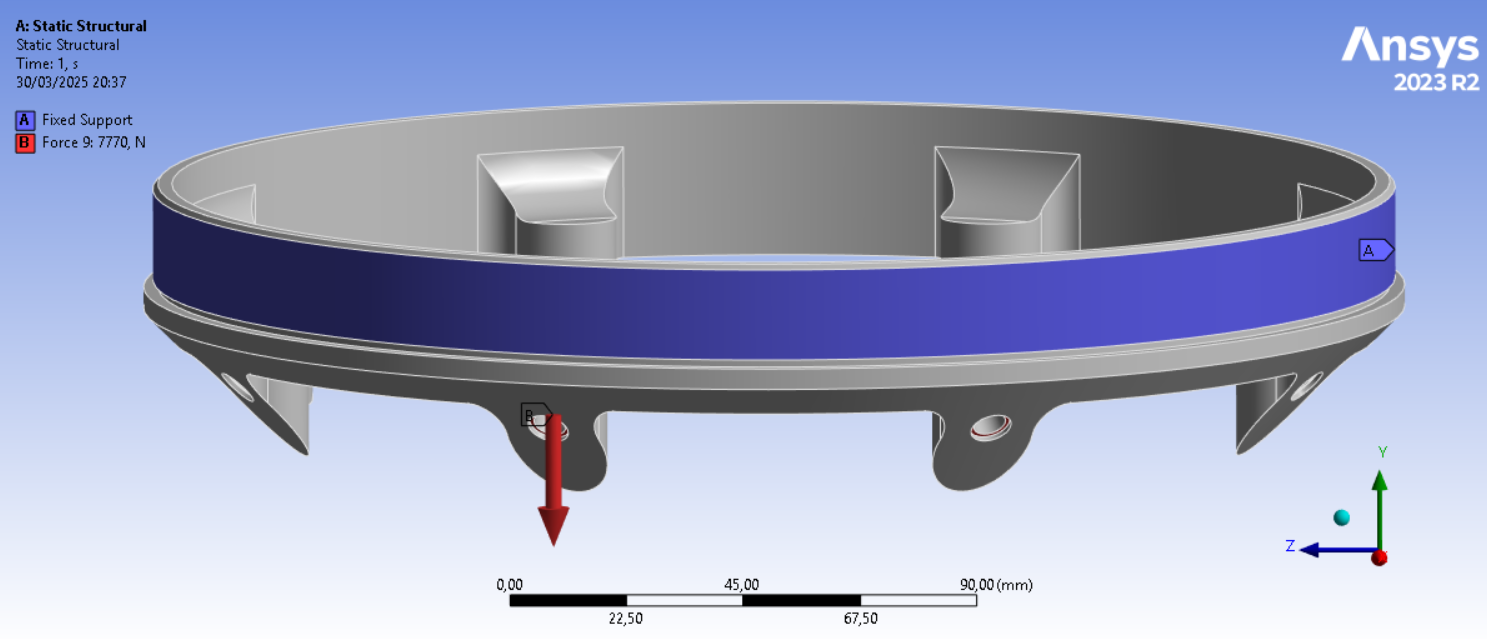

The following boundary contitions were applied:

-

Clamped surfaces: The glued surface of the coupler has been blocked in all directions and rotations.

-

An downwards (negative y) axial force of 7770 N has been applied on the 8 surfaces at the exit of the screw holes.

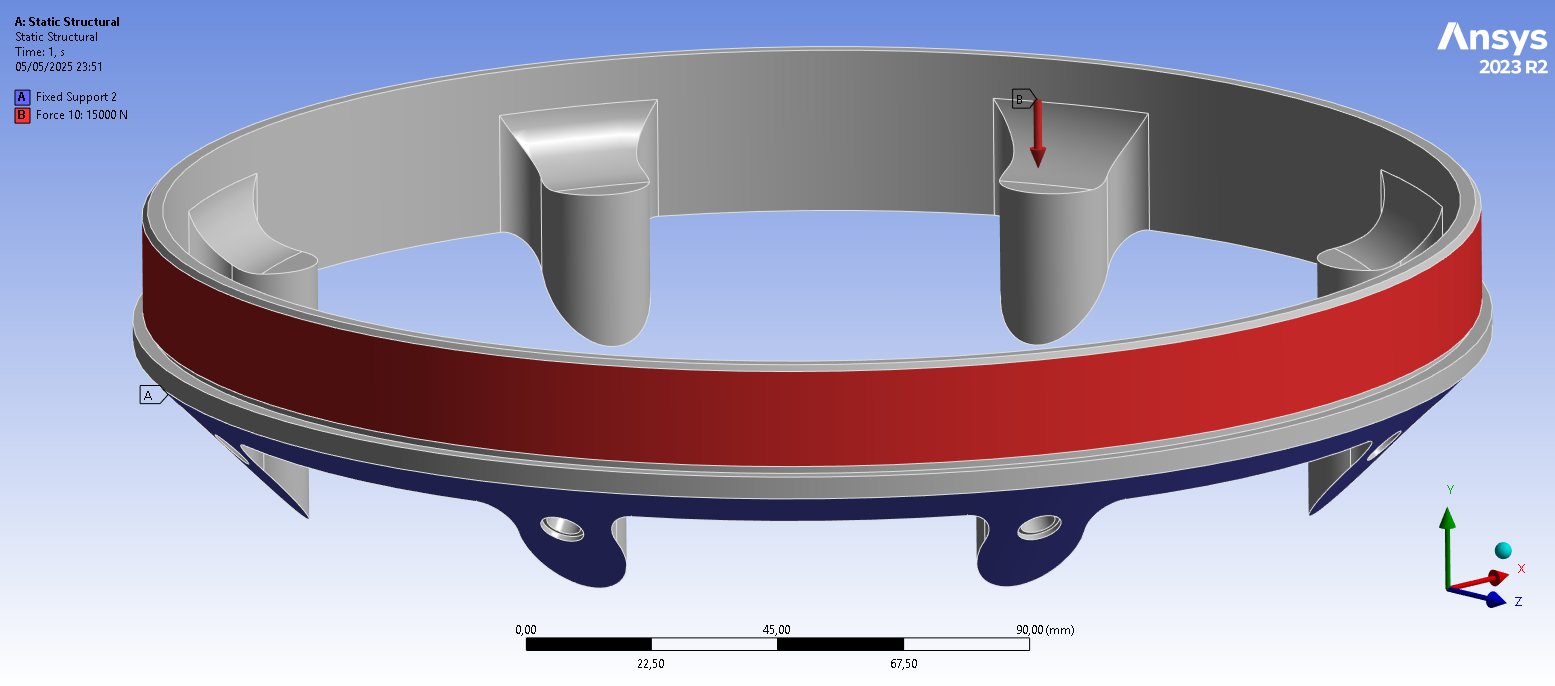

¶ Compression load case

The following boundary contitions were applied:

-

Clamped surfaces: The conical surface of the coupler has been blocked in all directions and rotations.

-

An downwards (negative y) axial force of 15000 N has been applied on the glued surface of the coupler.

¶ Moment load case

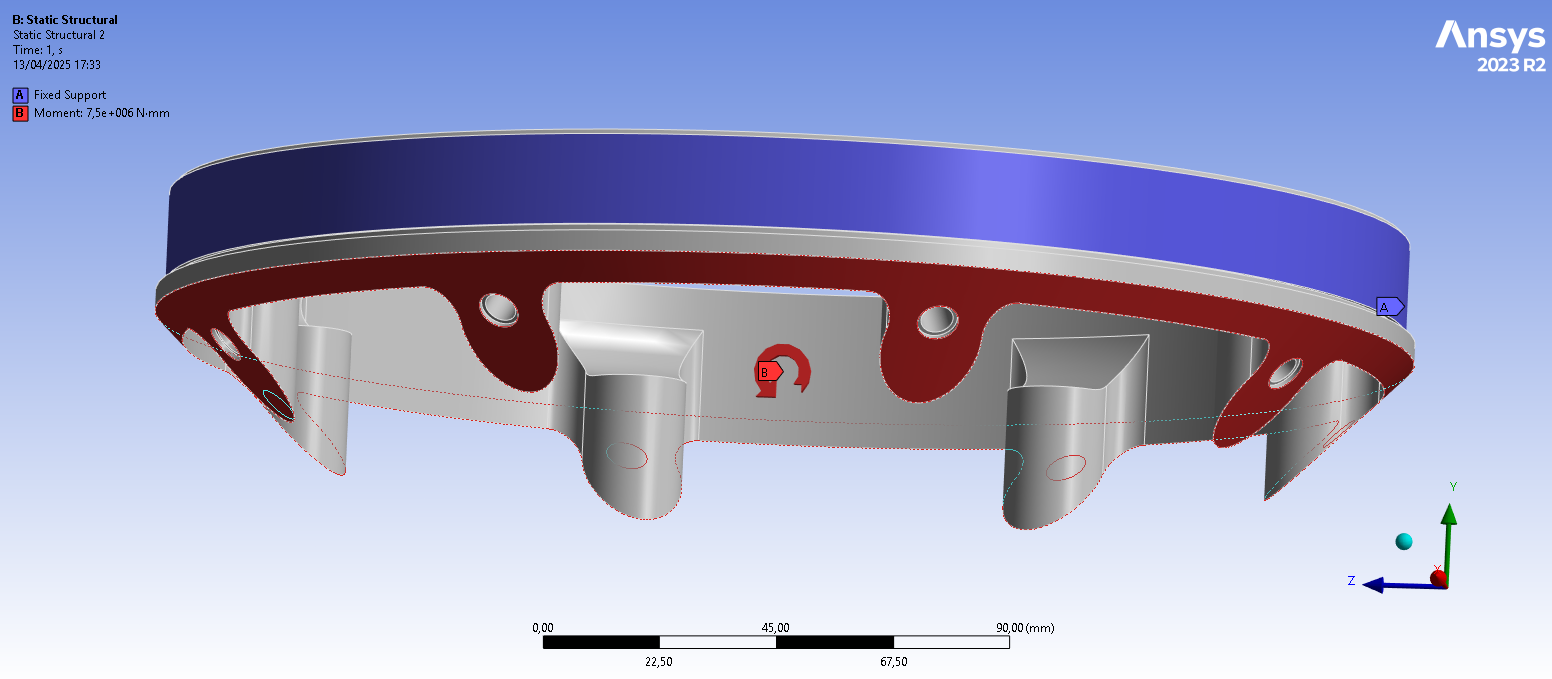

The following boundary contitions were applied:

-

Clamped surfaces: The glued surface of the coupler has been blocked in all directions and rotations.

-

A moment of 7500000 Nmm around the x-axis has been applied on the conical surface of the coupler.

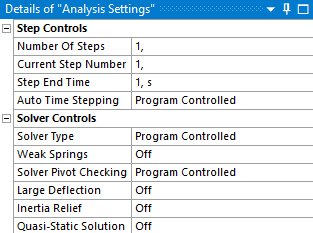

In both cases the analysis settings were left program controlled which gives the following settings:

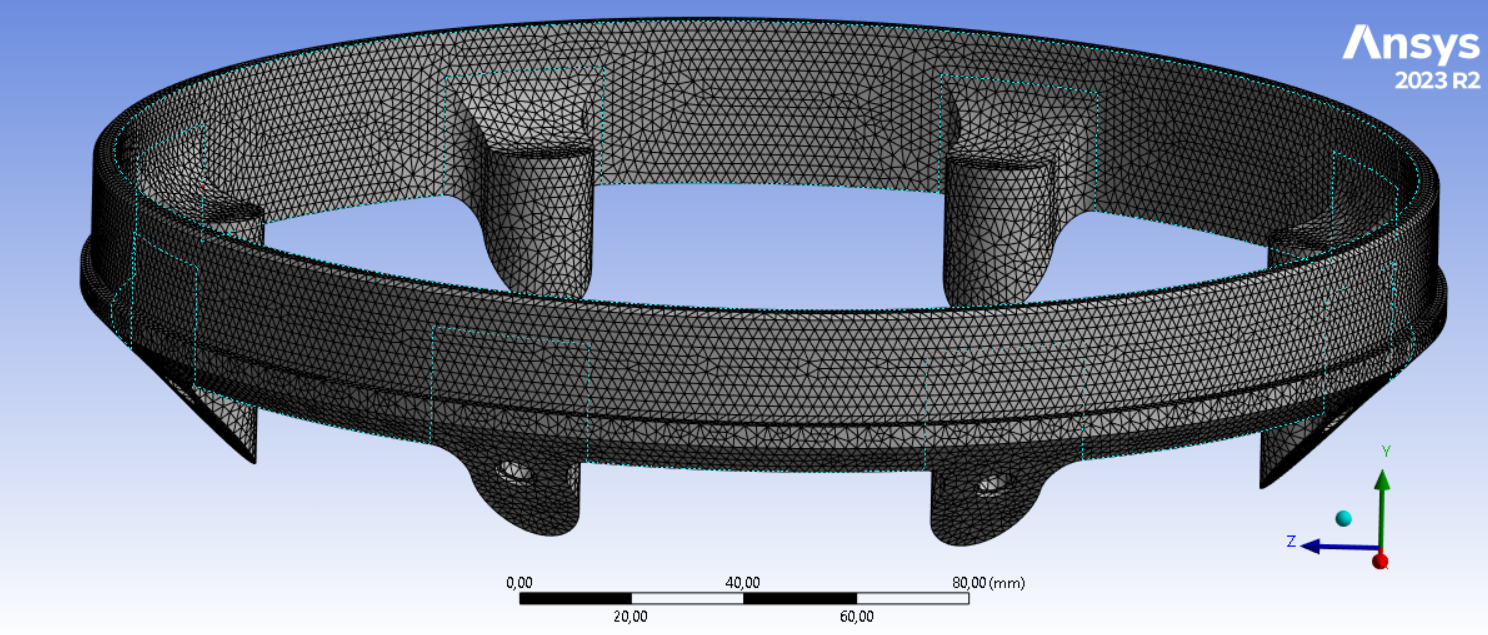

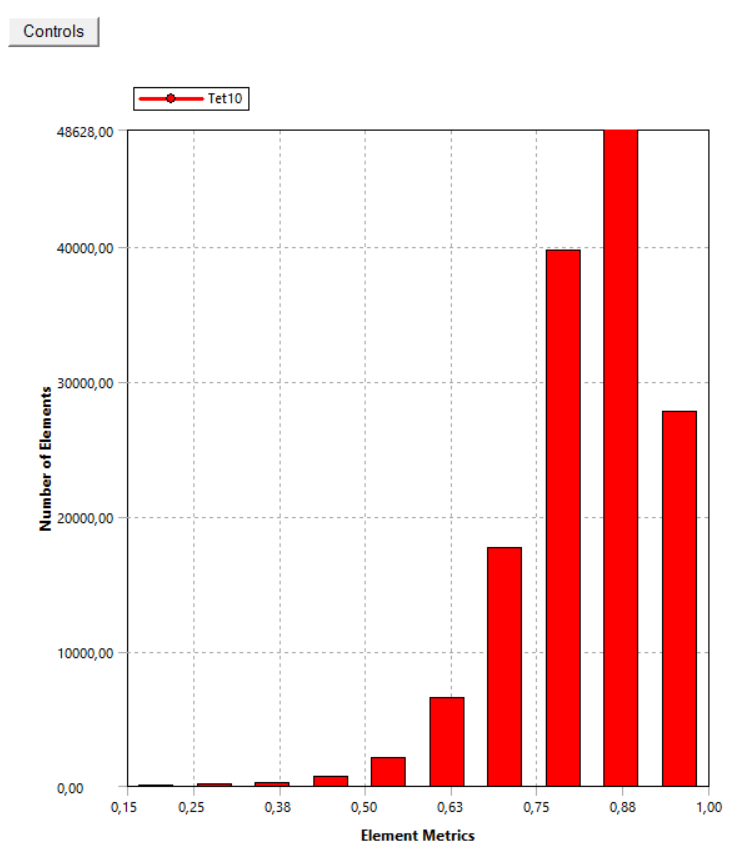

¶ Mesh

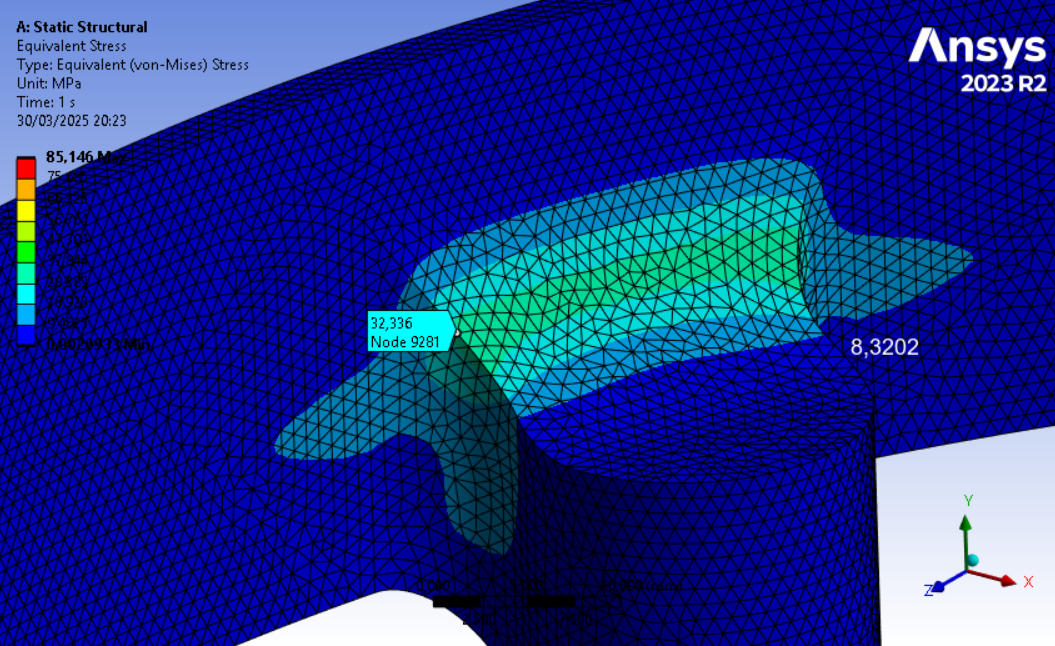

We choose to use the 3D solid elements to realize our analysis. The mesh is constituted of tetrahedral mesh of quadratic element order (Tet10).

To verify mesh convergence, we probed the stress under the tension load case, at the same node where the coupler is subjected to bending:

| Size (mm) | 2 | 1 |

|---|---|---|

| Stress (MPa) | 32.29 | 32.33 |

| Deltas (%) | / | 0.12 |

The 'size' quantity refers to the sizing setting applied on the geometry.

We use the mesh with an element sizing of 2 mm as it is sufficiently refined (less than 2% difference with the finest mesh).

The final mesh is the one generated with an element sizing of 5 mm on the whole geometry. It contains 143022 elements and 229983 nodes. The average element quality is around 85%.

The following pictures illustrate the mesh as well as the element quality of the mesh.

¶ Outputs

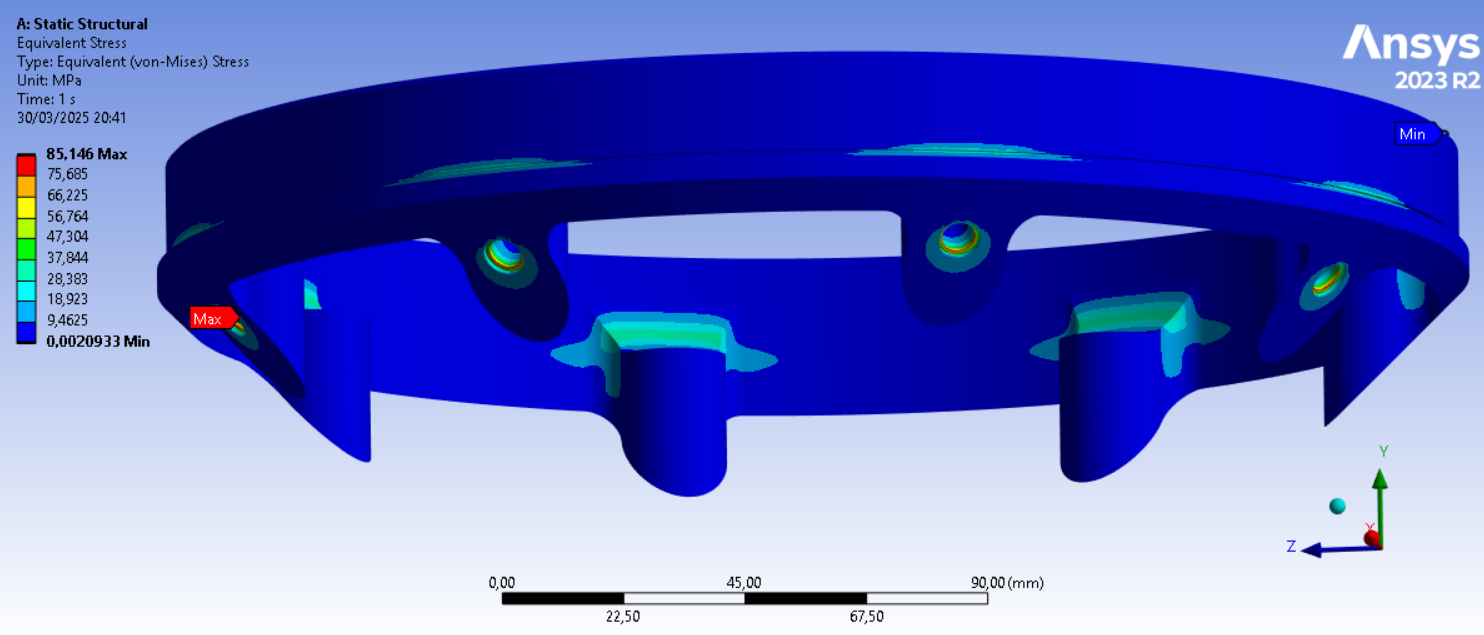

¶ Tension load case

The maximal stress is found on the edge of a screw hole so it might be a concentration of constraints But it is not exceedingly high compared to the surrounding constraints so we still take it into account. It has a value of 85.15 MPa. The couplers being manufactured in 2050-T84 aluminum alloy, its yield strength is of 476 MPa, which is not exceeded.

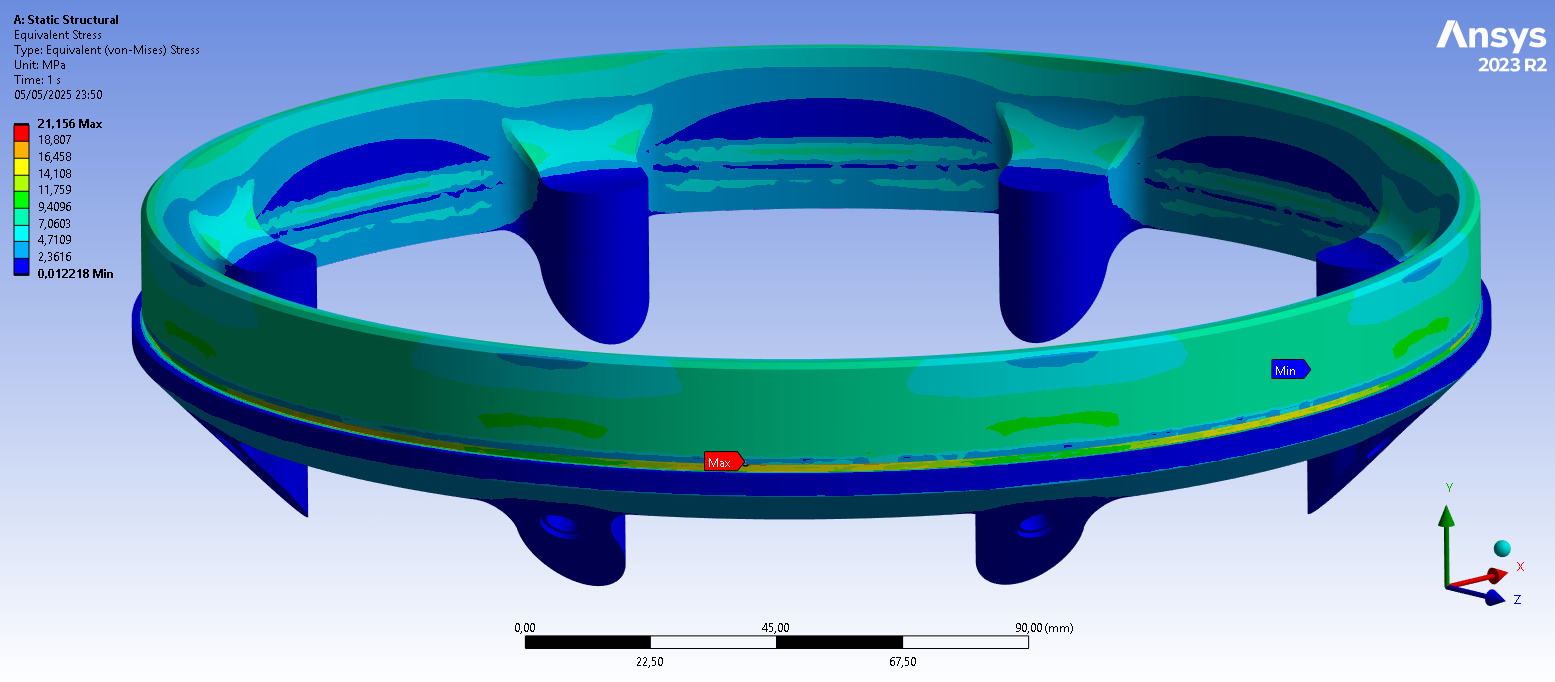

¶ Compression load case

The maximal stress is found in the grove under the glued part of the coupler. It has a value of 21.156 MPa. The couplers being manufactured in 2050-T84 aluminum alloy, its yield strength is of 476 MPa, which is not exceeded.

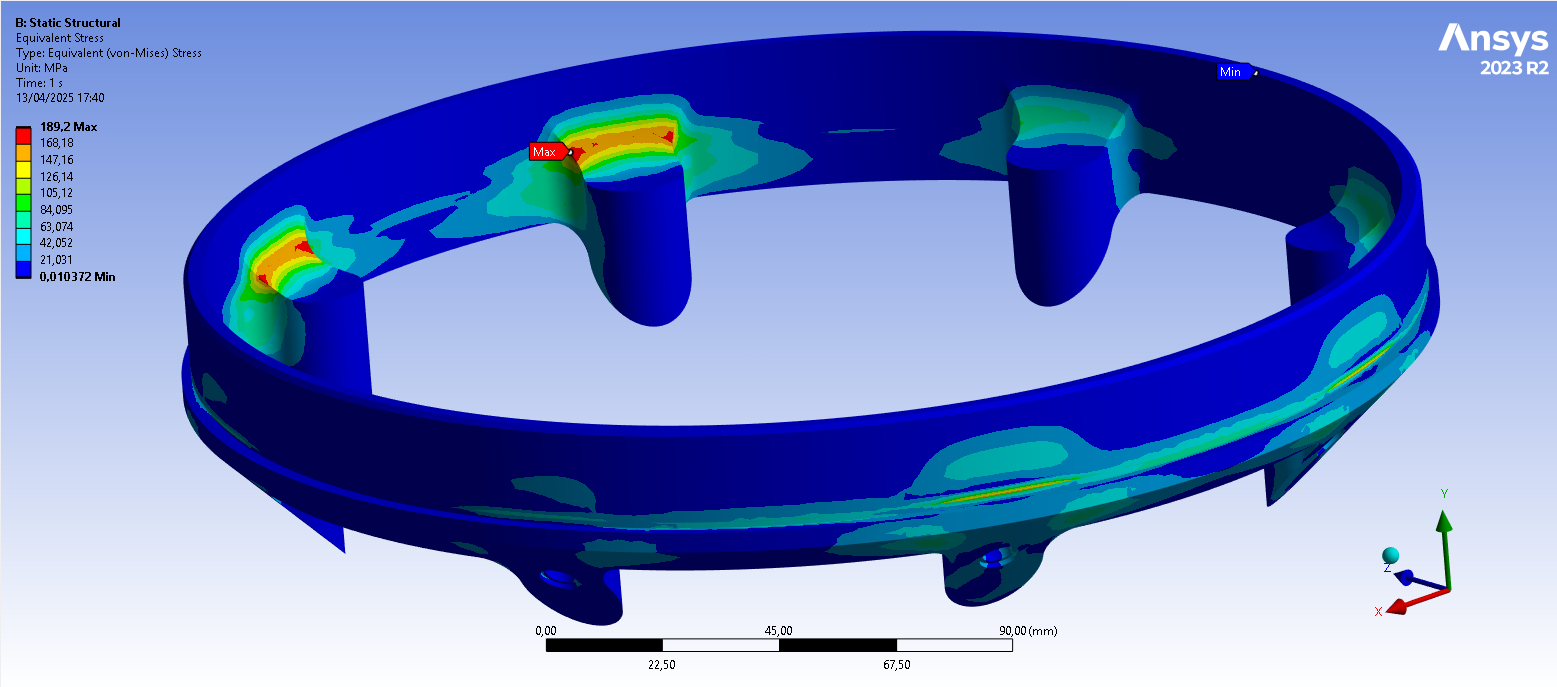

¶ Moment load case

The maximal stress in this case is found on one of the 8 extrusions which house the screw holes. it has a value of 189.2 MPa. The couplers being manufactured in 2050-T84 aluminum alloy, its yield strength is of 476 MPa, which is not exceeded.

¶ Margin of Safety

The formula of the minimum Margin of Safety being the following:

We have:

¶ Force load case

¶ Compression load case

¶ Moment load case

In all cases we have a MoS greater than the required 0.25.

¶ Conculsions

The main focus of the simulation was to determine if the tensile strength of the material is exceded under the loads which the coupler is supposed to withstand.

¶ Force load case

The simulation results indicate that under the load case of 7700 N, the maximal von mises equivalent stess within the part has a value of 85.15 MPa which corresponds to a margin of safety of 4.59 which is well over the 0.25 required. Therefore, this load being higher than the 4800 N required we can conclude that the following requirement is verified.

- 2024_C_SE_ST_RECOVERY-BAY_REQ_13 Upper shockplate load case

The shockplate in the recovery bay of the FH I LV shall withstand [4800]N of axial tensile loads.

The simulation results indicate that under such a load, the maximal von mises equivalent stess within the part has a value of 21.156 MPa which corresponds to a margin of safety of 21.5 which is well over the 0.25 required. Therefore, we can conclude that the following requirement is verified.

- 2024_C_SE_ST_COUPLER_REQ_20 Coupler load case - compression

The Coupler shall withstand [15000]N of compression loads.

¶ Moment load case

Furthermore, the results indicate that under the load case of 7500 Nm, the maximal von mises equivalent stess within the part has a value of 189.2 MPa which corresponds to a margin of safety of 1.52 which is well over the 0.25 required. Therefore, we can conclude that the following requirement is verified and we can validate the design for FH 9.

- 2024_C_SE_ST_COUPLER_REQ_21 Coupler load case - bending

The Coupler shall withstand [7500]Nm of bending moment.