¶ Introduction

The Boattail is one of the main components of Engine Bay. Its primary objective is to streamline airflow and reduce drag at high speeds, thereby improving aerodynamic efficiency and stability during flight. One of its secondary goals is to protect the engine from sustaining any possible damages at touch down and, together with the Exhaust Shield, avoid any of the hot gases produced by the exhaust nozzle from re-entering the EB and damaging internal components.

¶ Definitions and Abbreviations

- EB: Engine Bay

- FT: Fixation Tree

- CFRP: Carbon-fiber-reinforced polymers

- DS-EB: Dual-Stage Engine Bay

- SS-EB: Single-Stage Engine Bay

- CNC : Computer Numerical Control

¶ Narrowing the Design Options

Due to the second design being a direct evolution of the first one, no formal trade-off analysis was made between competing configurations. The design was iteratively improved in response to updated requirements. As mentioned in the Thrust Plates DJF, a strategic decision was made to prioritize mass reduction in order to enhance rocket performance, at the expense of optimal aerodynamic shaping.

¶ Requirements and Design Criteria

¶ Requirements

These are main requirements that motivated this change and guided us through the conception of the current version of the Boattail:

-

2024_C_SE_ST_ENGINE-BAY_REQ_05

Boattail length

The ENGB shall have a boattail length of [250][+/-20]mm -

2024_C_SE_ST_ENGINE-BAY_REQ_11

Engine bay structure mass

The total mass of the ENGB structure shall be [6000][+/-600]g. -

2024_C_SE_ST_ENGINE-BAY_REQ_13

Exhaust isolation

The ENGB structure shall isolate the engine exhaust from it's internals -

2024_C_SE_ST_ENGINE-BAY_REQ_15

Engine Shock Protection

The boattail shall protrude at least [20]mm rearwards of the engine nozzle's end -

2024_C_SE_ST_ENGINE-BAY_REQ_17

Boattail load case

The boattail shall withstand [2000]N of axial compression loads.

¶ Functional Description

The Boattail’s main function is to enhance aerodynamic efficiency by reducing drag and managing the flow of exhaust gases. In order to achieve this, the boattail must fulfill multiple sub-functions:

- Streamlining the EB's rear profile to minimize turbulence.

- Redirecting and isolating hot exhaust gases to prevent thermal damage to the internal systems.

- Providing structural support and shock absorption during landing.

- Integrating with the Exhaust Shield and Thrust Plate, ensuring a coherent system architecture.

These sub-functions require mechanical robustness, heat resistance, and precise alignment with adjacent components.

¶ Function Tree

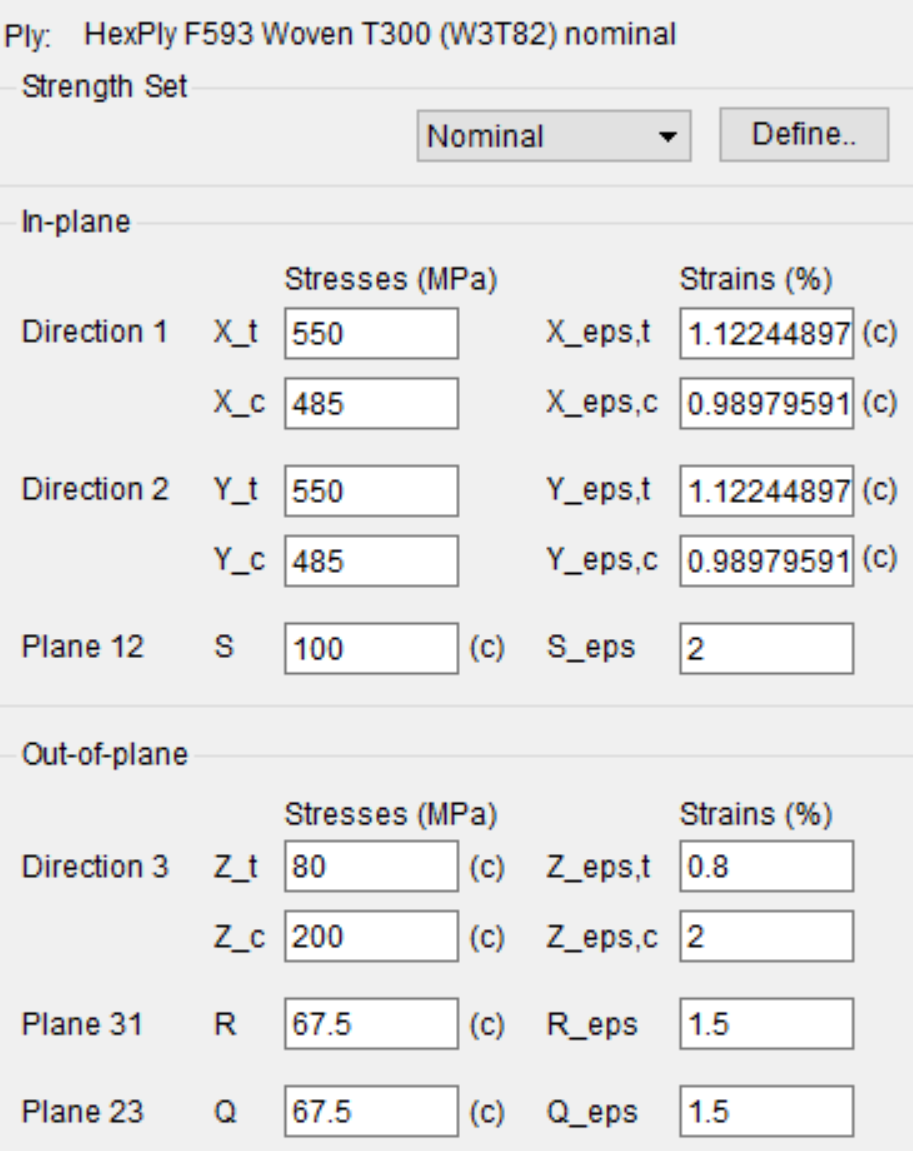

¶ Preliminary lay-up definition

- Material: HexPly © W3T-282-42'-F593-14

- Weave: plain

- [mm]

| [GPa] | [GPa] | [MPa] | [MPa] |

|---|---|---|---|

| 49 | 42 | 550 | 495 |

¶ Lay-up Definitions

- x is the direction of 0° orientation

- t: traction

- c: compression

- f: flexion

- s: shear

First Ply Failure (FPF) analysis is conducted with Tsai-Wu criterion

| ID | Lay-up Description |

|---|---|

| E | (0/+45) |

| D | (+45/0/+45) |

| C | (0/+45/0/+45/0) |

| B | (0/+45/−45/−45/+45/0) |

| A | (90/+45/0/0/+45/90) |

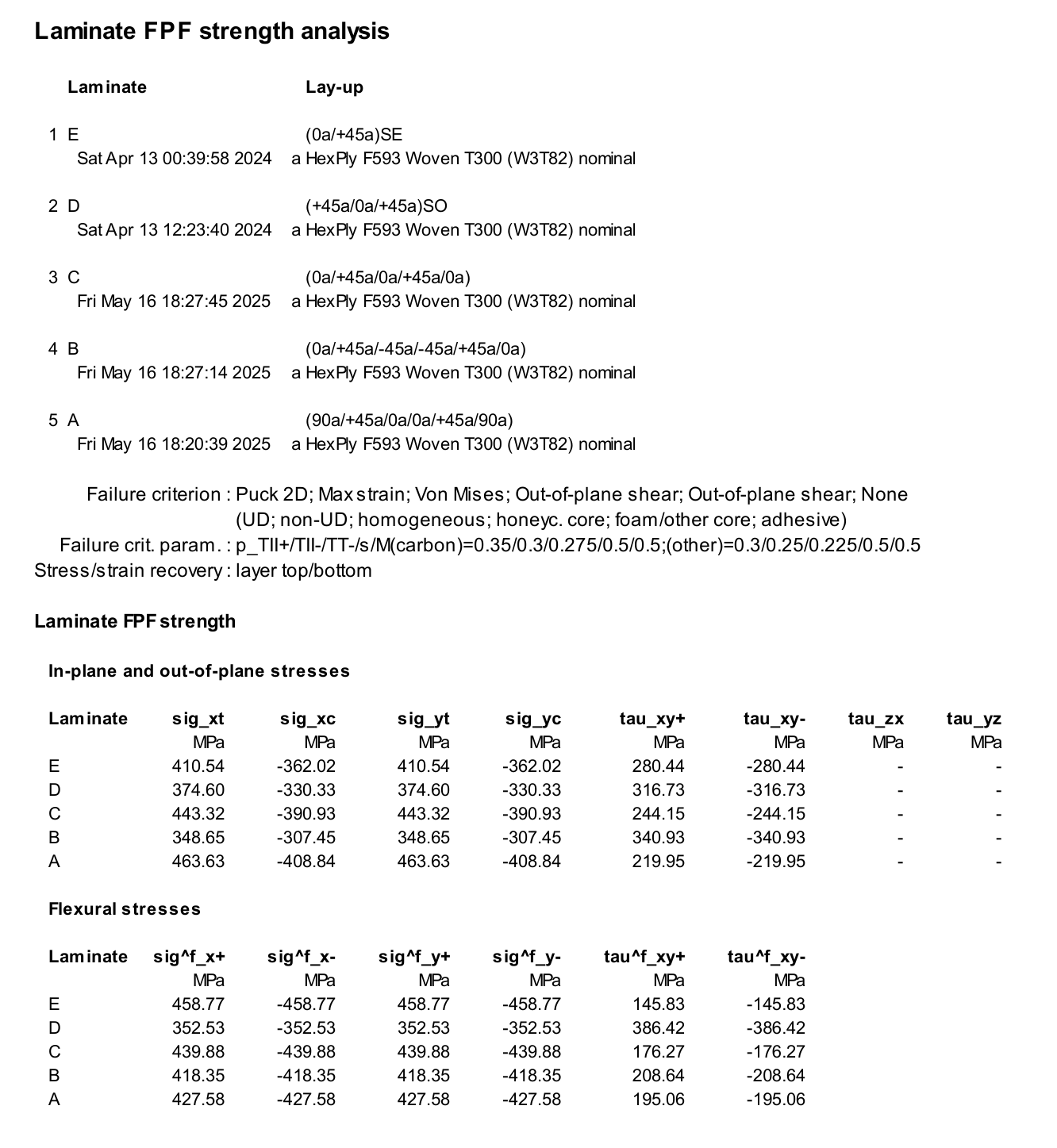

¶ In-Plane & Out-of-Plane Strength

| Lay up | \ | \ | \ | \ | \ \tau_ |

|---|---|---|---|---|---|

| E | 410.54 | −362.02 | 410.54 | −362.02 | ±280.44 |

| D | 374.60 | −330.33 | 374.60 | −330.33 | ±316.73 |

| C | 443.32 | −390.93 | 443.32 | −390.93 | ±244.15 |

| B | 348.65 | −307.45 | 348.65 | −307.45 | ±340.93 |

| A | 463.63 | −408.84 | 463.63 | −408.84 | ±219.95 |

¶ Flexural Strength

| Laminate | \ | \ | \ |

|---|---|---|---|

| E | ±458.77 | ±458.77 | ±145.83 |

| D | ±352.53 | ±352.53 | ±386.42 |

| C | ±439.88 | ±439.88 | ±176.27 |

| B | ±418.35 | ±418.35 | ±208.64 |

| A | ±427.58 | ±427.58 | ±195.06 |

¶ Comparative Insights

¶ Highest In-Plane Strength:

- A has the best in-plane tensile/compressive performance in both directions.

- C is close and more balanced in compression and tension across all directions.

¶ Highest Shear Strength:

-

B and D offer the best in-plane shear resistance:

- B: ±340.93 MPa

- D: ±316.73 MPa

¶ Flexural Strength:

- E has high axial flexural strength, but weak shear under bending.

- D dominates in shear flexion (±386.42 MPa), which is important for resisting bending moments.

¶ Final Recommendation

Selected Lay-up: [90°, +45°, 0°, 0°, +45°, 90°] → Lay-up A

¶ Why this Lay-up?

- Strongest overall performance in axial tension and compression

- Excellent in-plane stiffness due to the 0° core and outer 90° layers

- Good flexural resistance with balanced ply orientation

- Most robust lay-up among all options tested

- Outperforms Lay-up C in axial and bending loads

- High safety margins under worst-case FEA loads

¶ Key Properties

- Total Thickness: 6 plies × 0.24 mm = 1.44 mm

- In-plane Modulus: E1≈E2≈39.5 GPa

This configuration provides maximum strength and stability, making it the safest choice for critical load conditions and bending scenarios. Perfect for final sizing in high-demand structural zones.

¶ Simplified geometry

To facilitate finite element modeling, the geometry of the Nosecone was simplified. The actual slightly curved shape was replaced with a truncated cone extending from the tip to the base of the Nosecone. This simplification helps avoid artificial stress concentrations at the convergence point of a full cone.

The dimensions used for this simplified cone are as follows:

- Upper diameter: 246.12 mm

- Lower diameter: 212.09 mm

- Projected length: 250 mm

This approach enables more stable modeling in the simulation software (Altair EsaComp), while maintaining a reasonable approximation of the distributed loads acting on the component.

¶ FEA

FE model

Boundary conditions: clamped at (, ), free at (, )

Element type: cylindrical shell

Caution: The results are partially dependent on mesh quality.

The FEA module in Altair EsaComp has notable limitations—particularly with large parts, where mesh refinement is restricted beyond a certain threshold.

While the absolute accuracy of the results may be limited, the outcomes remain consistent across different laminate configurations, especially when a reasonably refined mesh is used.

As long as the same mesh settings are applied, comparative evaluations between lay-ups are reliable due to the presence of systematic rather than random errors.

Overall, the analysis is semi-quantitative, but sufficiently accurate to support informed laminate selection.

The analysis gives reserve factors (RF) as outputs.

The part resists load if

Here is a synthesized summary of the Laminate FPF strength analysis for all lay-ups (A–E) using the available data, focusing on both in-plane and flexural strength. The summary includes key comparison points, highlights, and concludes with a recommendation similar in style to your previous report.

¶ Definitive Lay-up

Among all structural constraints, bending remains the most critical. After evaluating the performance of each laminate under axial traction, compression, and flexion, the laminate A was selected for its robust and balanced performance.

The lay-up [0, +45]S was rejected early due to insufficient strength in nearly all loading scenarios. Similarly, symmetric lay-ups such as [45, 0, 45]x (with x = S or SO) were less reliable, especially in flexion, where they failed primarily due to shear. Conversely, [0, +45, 0]x lay-ups tend to fail in compression under flexion, which is generally a safer and more progressive failure mode.

After comparing more complex options (6-ply lay-ups B and A), lay-up A stood out by offering:

- Excellent axial compression and tension resistance

- Very good shear and flexural strength

- Improved out-of-plane behavior thanks to outer 90° plies

- More balanced and quasi-isotropic behavior in the transverse direction

- Better global structural damping and delamination resistance

Although slightly thicker and heavier than 5-ply laminates, its mechanical performance justifies the additional ply.

Chosen Lay-up: [90, +45, 0, 0, +45, 90]

Thickness: 6 plies × 0.24 mm = 1.44 mm

Effective modulus:

This configuration will be used for further validation, including buckling, vibration, and potential impact analysis in later stages.

¶ Interfaces

The Boattail interfaces with several key components of the rocket architecture, both mechanically and functionally:

Airframe Interface:

The Boattail connects directly to the lower structure of the Airframe via a bolted interface. This connection must ensure both structural continuity and aerodynamic smoothness at the transition point.

Engine Bay (EB) Structure:

The Boattail is structurally integrated into the Engine Bay and shares a common fixation system (FT). The connection is both mechanical and thermal, requiring careful material selection and thermal isolation strategies to prevent heat transfer from the nozzle exhaust.

Exhaust Shield:

Interfaces thermally and spatially with the Exhaust Shield to ensure full coverage from exhaust gases. This relationship is critical in maintaining internal EB component safety during engine burn and preventing backflow of hot gases.

¶ Design Constraints

¶ Constraints for Production

Manufacturing Process:

The Boattail is produced using infusion molding in a female mold, which necessitates careful layering and mold preparation. The new version includes increased CFRP layers to handle additional structural loads, particularly in light of the full-rocket load-bearing requirement.

Tooling and Mold Compatibility:

The Boattail mold was derived from the Nosecone's mold geometry, implying tight tolerances and compatibility in interface profiles, which restrict rapid geometry iterations.

Assembly Order:

Some Boattail components must be integrated prior to full Engine Bay assembly to allow for accurate alignment and fastening, limiting accessibility during later integration stages.

¶ Constraints for Operation

Thermal Considerations:

Operators must ensure correct positioning of thermal insulation between the Boattail and internal components. Improper sealing can cause recirculation of hot exhaust gases, damaging avionics or EB structural components.

Handling Precautions:

Due to the Boattail's role in full rocket support, it must be handled using specific load-bearing jigs during transport and integration, especially when under compressive load.

¶ Other Constraints

Transport and Storage:

Given its size and structural fragility when not integrated, the Boattail must be stored with custom foam supports. Flat storage is discouraged to avoid deformation of contact surfaces.

Reusability:

Due to exposure to high thermal and mechanical stresses, particularly from exhaust and touchdown impacts, the Boattail is considered a limited-reuse component unless post-flight inspection confirms structural integrity.