¶ 2025_C_ST_Shockplate_FEA

This document aims to present the method used to analyse with finite elements software the shockplate of the Firehorn rocket.

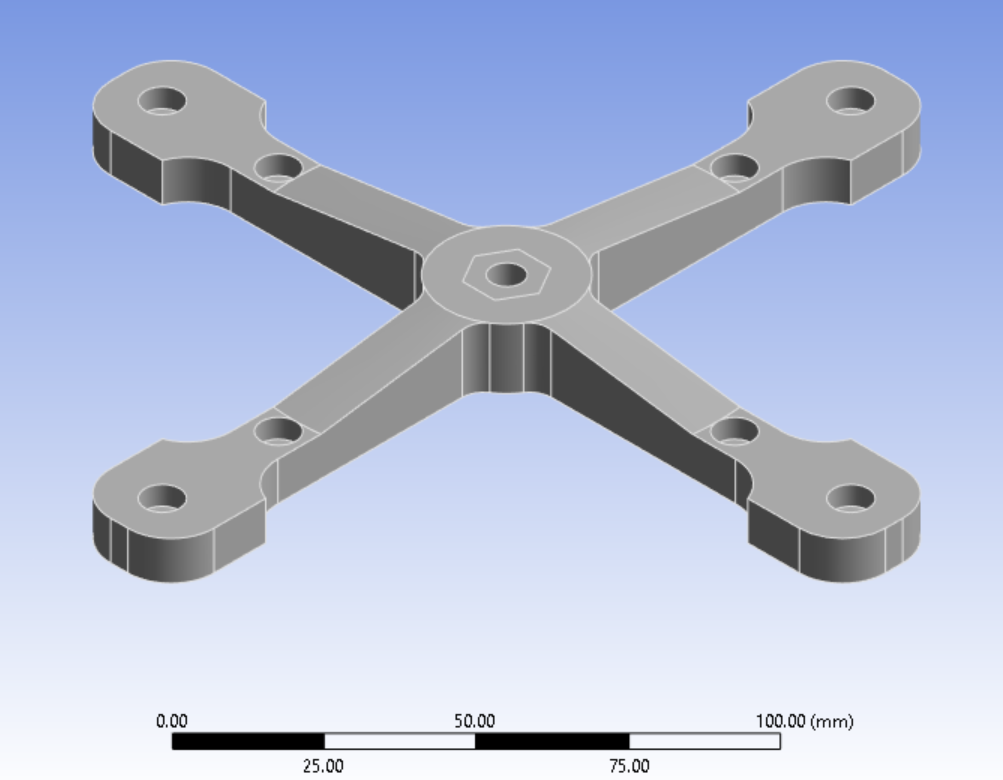

¶ Geometry and Function

The Shockplate is the part directly connected to the parachute, therefore it is the first part that reacts to the force of the parachute when it is deployed. The shockplate is also connected to the recovery bay through the coupler system with 4 fixation points.

¶ Material

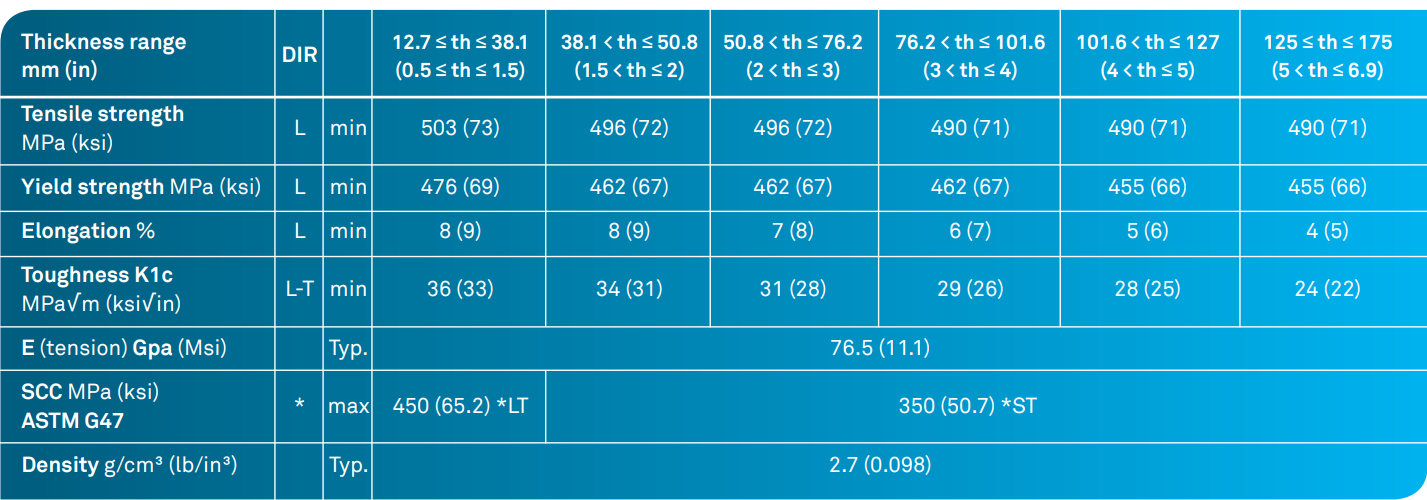

The thrustplate is machined in 2050-T84 alloy. This alloy has the following properties:

¶ Load case

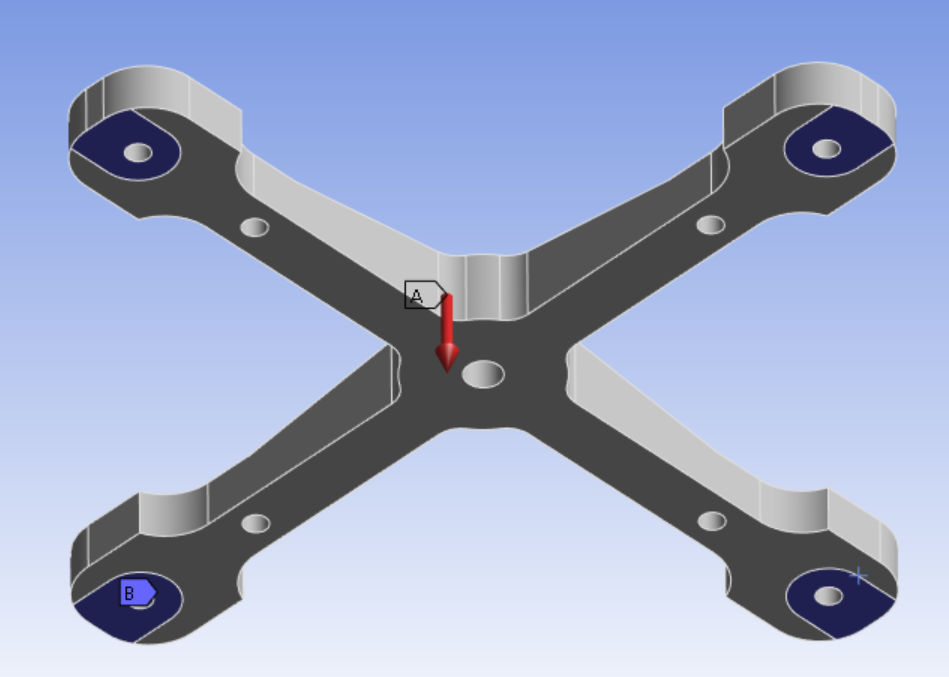

The force applied on the shockplate is an axial force of 4800 N applied on where the bolt would stand

¶ Finite Element Analysis

¶ Software

The software used for the FEA analysis was Ansys, ans the CAD of the piece was made using Solidworks

¶ Type of simulation

The simulation performed was a static structural analysis to estimate the Von mises constraints for the load case of 4800 N

¶ Goal of the Simulation

The goal of the simulation is to validate that the thrustplate can withstand a load of 4800 N the designated engine surface with a MoS of 0.25, knowing that the material yield strength is 476 MPa.

¶ Inputs

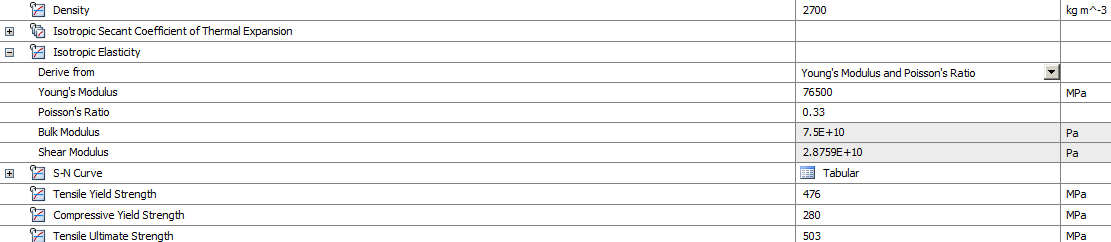

We use the following unit system: mm-t-N-s-mV-mA

The material properties used were:

The boundary counditions were:

- The faces directly in contact witht the coupler are in fixed support, and the force is directed in -z

Time was not taken into account for these simulations.

¶ Mesh

¶ Different mesh used

The three meshes used were 0.5mm, 1mm and 2mm

¶ Mesh refinement

No refinement has been applied.

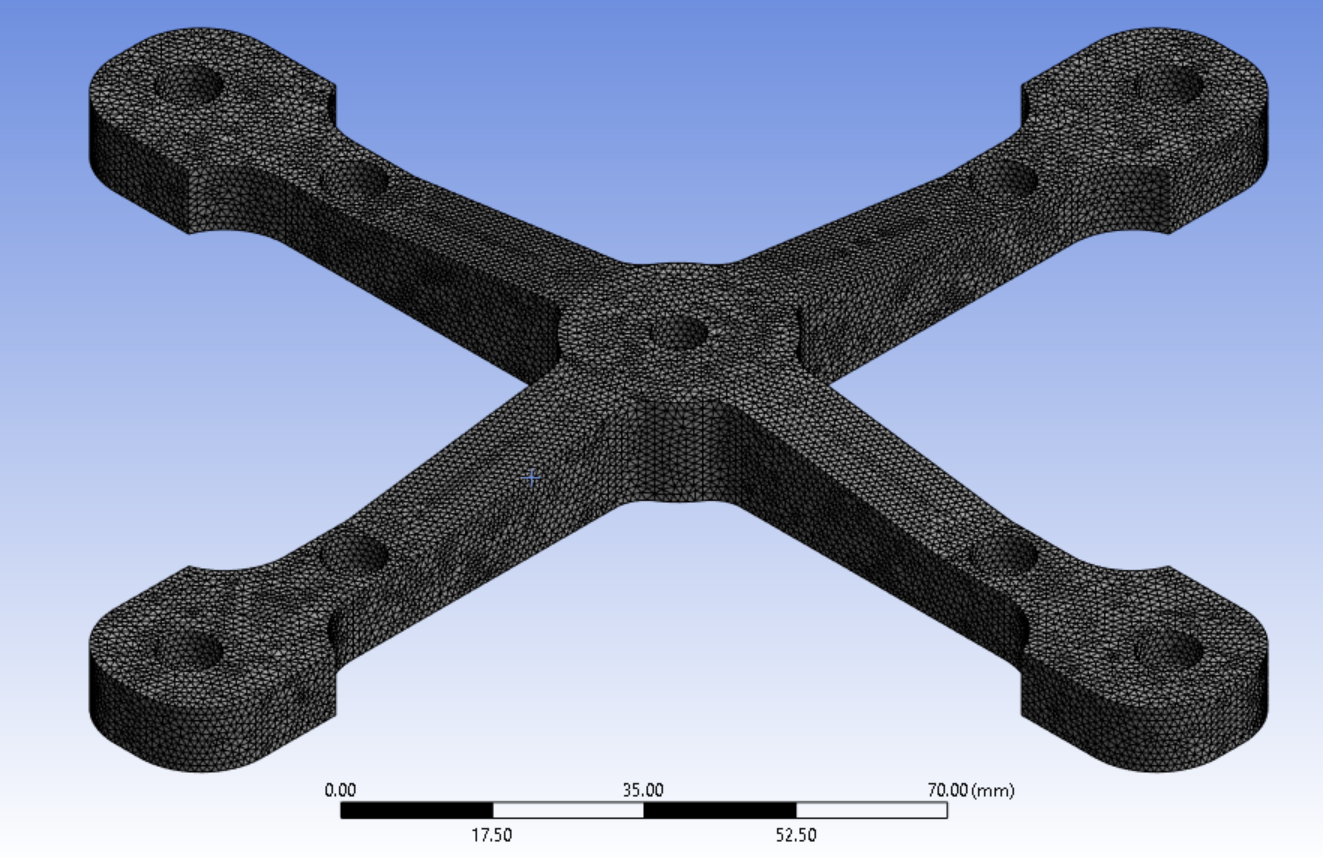

¶ Final mesh used Example 2mm

Here is a picture of the 2mm mesh

¶ Outputs

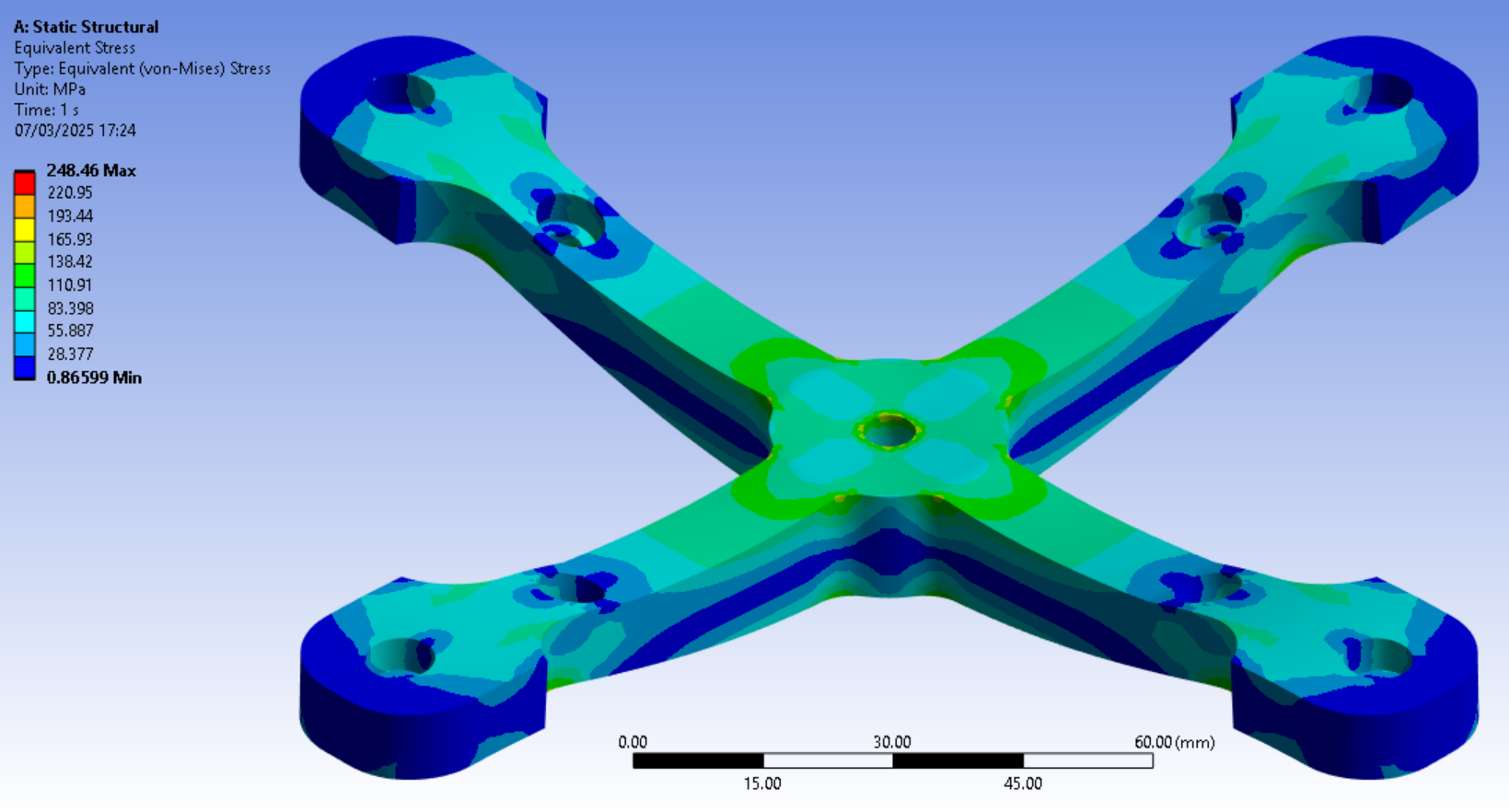

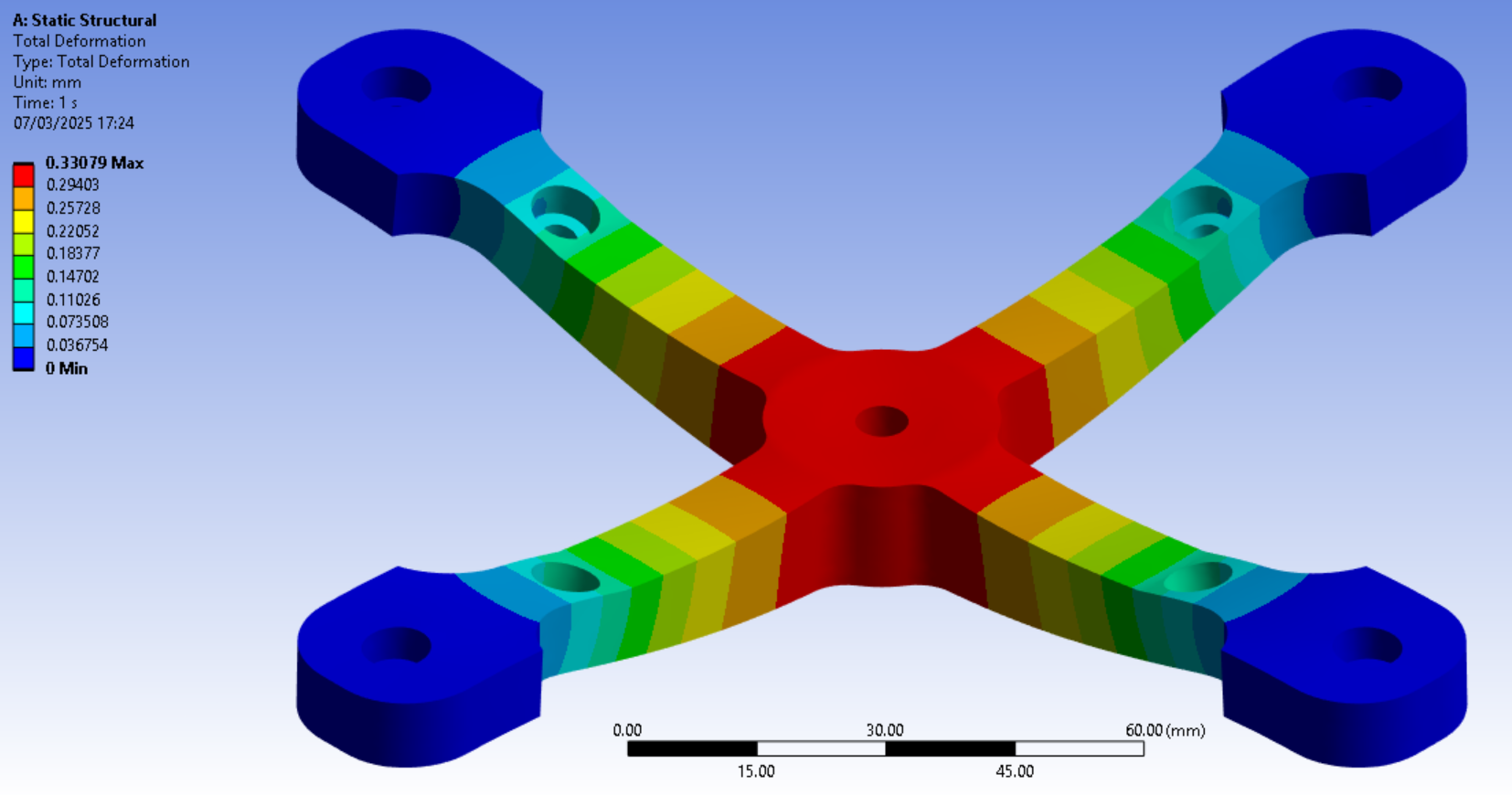

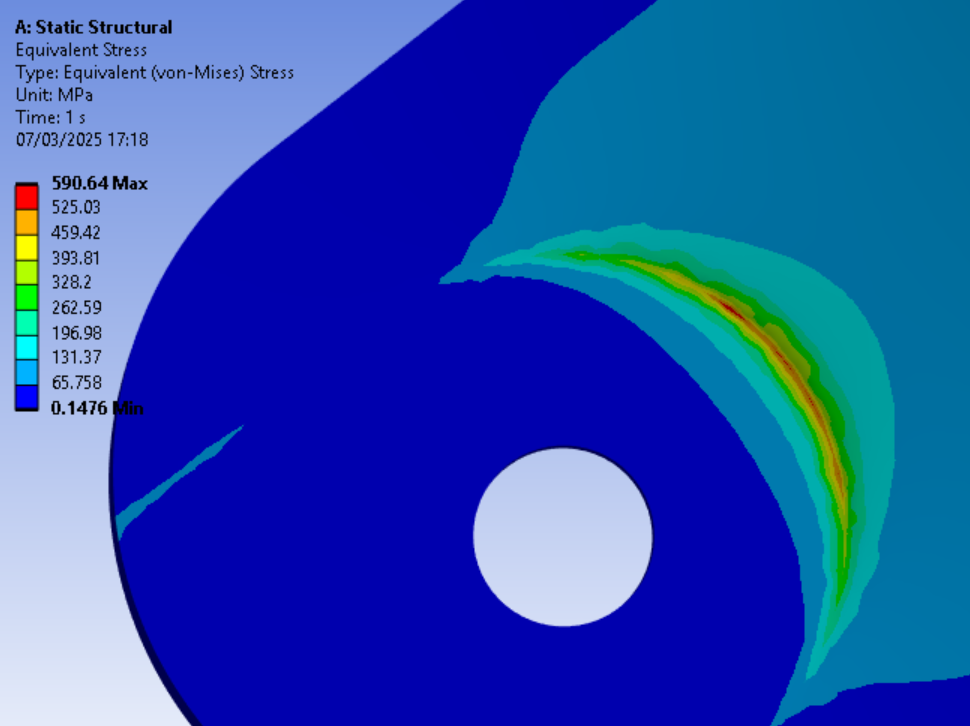

Here is the simulation for the 2mm mesh:

For the equivalent stress:

For the total deformation:

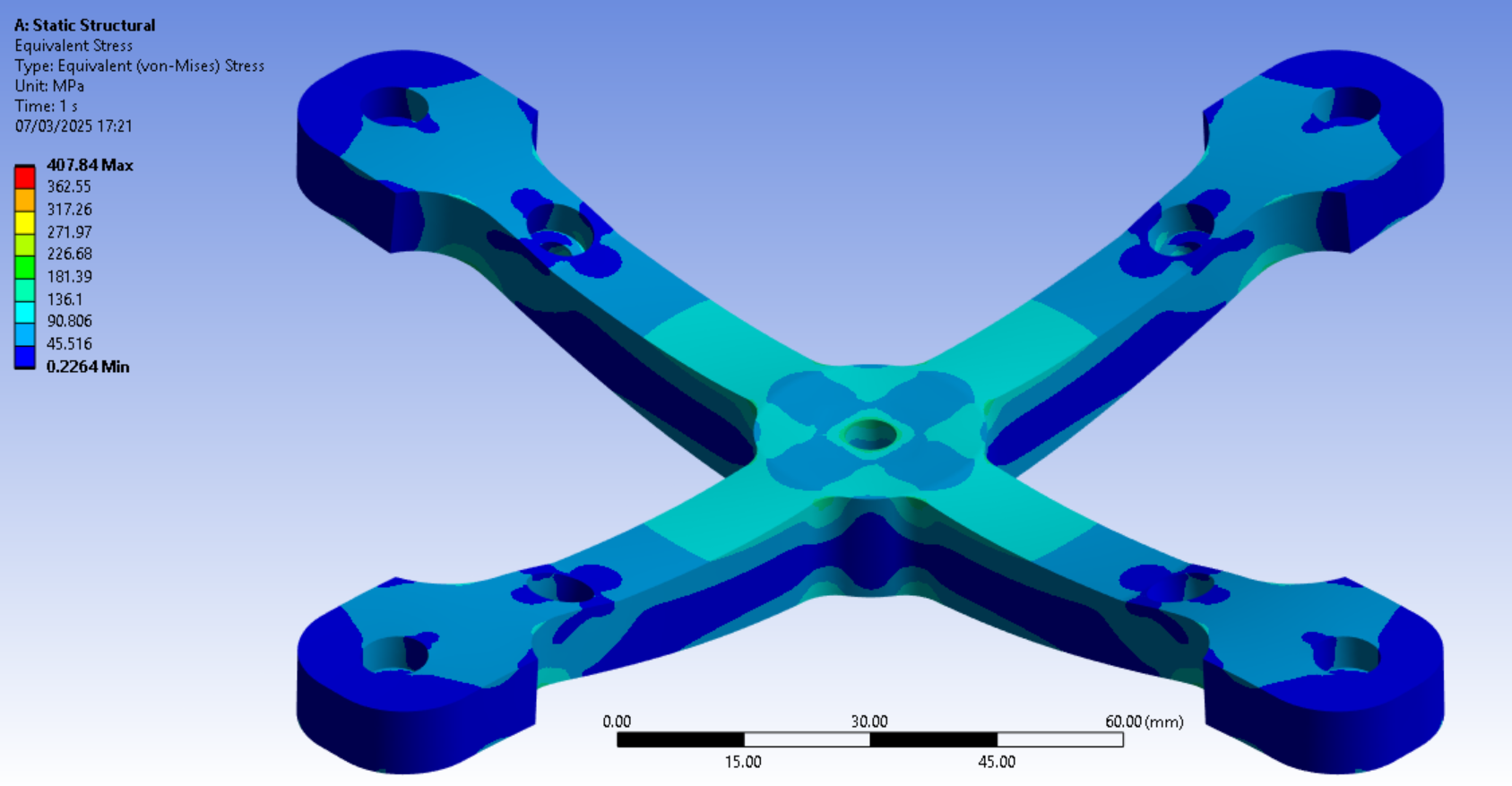

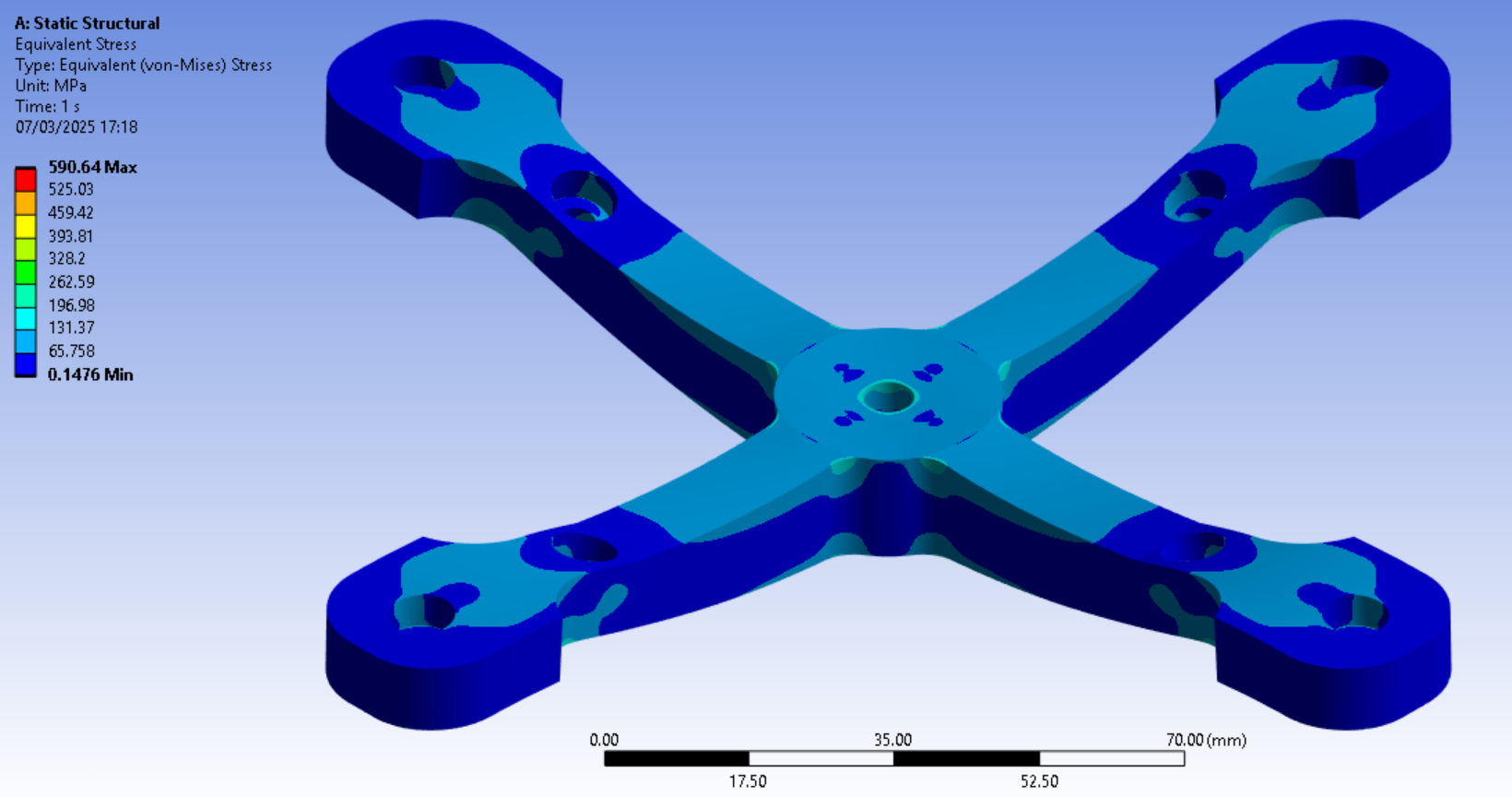

Here is the simulation for the 1mm mesh:

For the equivalent stress:

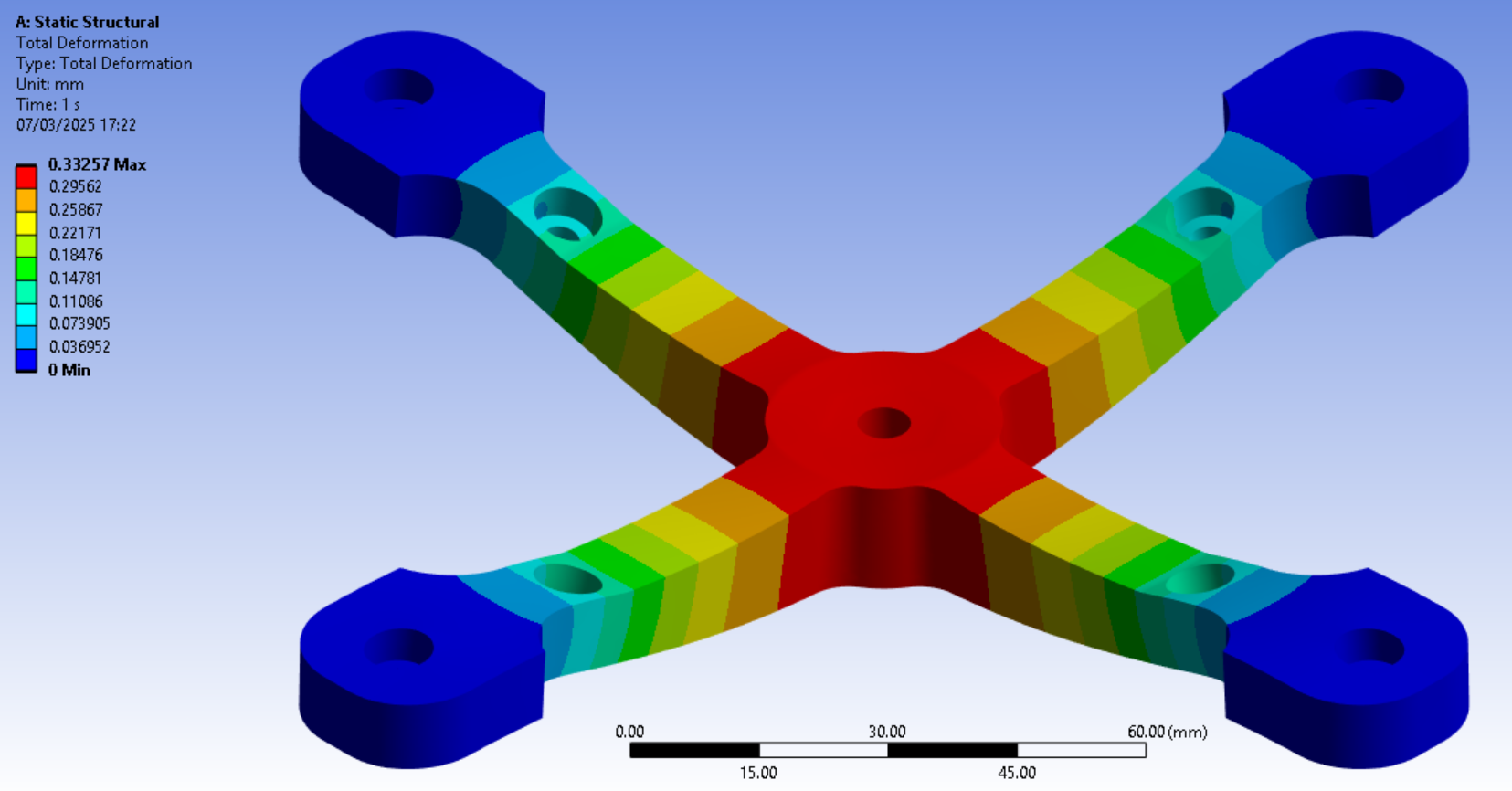

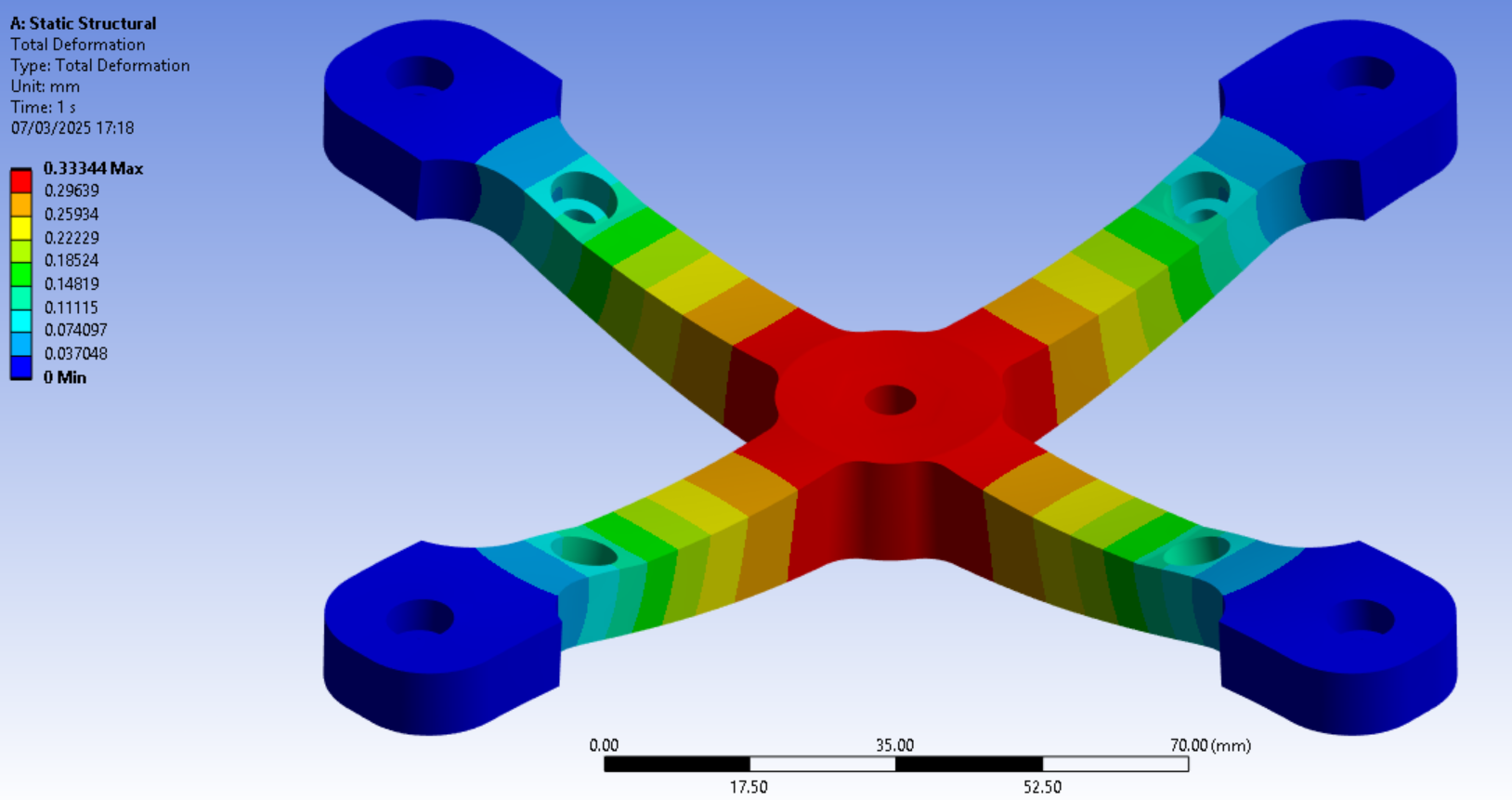

For the total deformation:

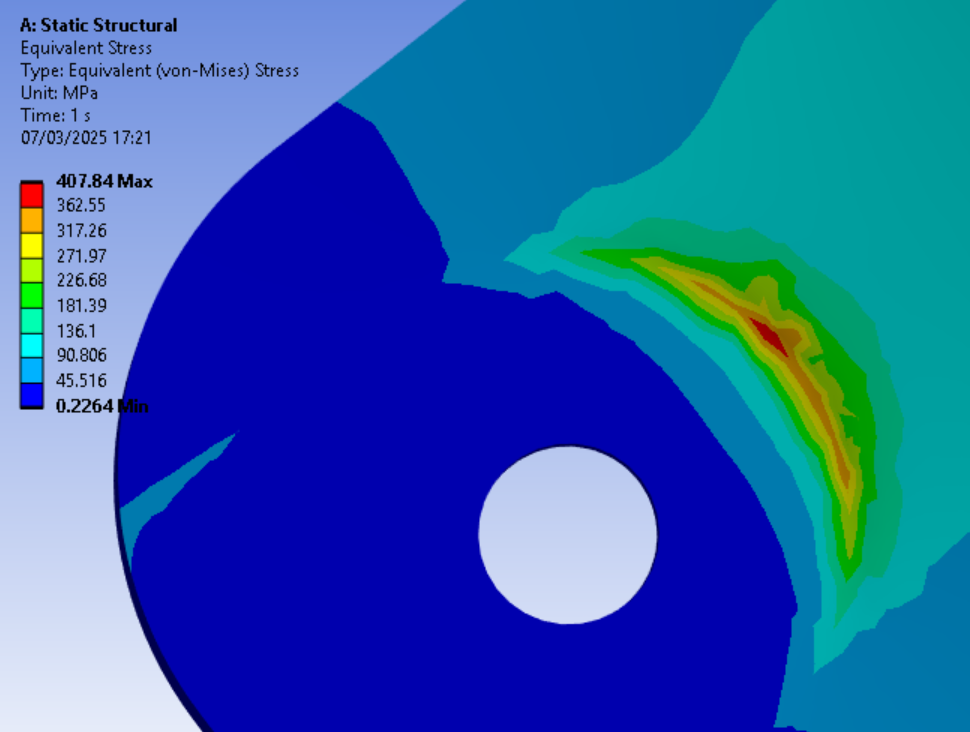

Zoom on the accumulation of stress:

Here is the simulation for the 0.5mm stress:

For the equivalent stress:

For the total deformation:

Zoom on the accumuéation of stress:

We see that our boundary conditions give an accumulation of stress on the edge of the fixed support, since these values of stress are only on the edge of the fixed support we can discard these values.

We are left with values of 262 MPa for 0.5 mm mesh, wich is the highest value of stress out of all meshes but still gives a MoS of 0.82 which is calculated with (476/262) - 1 = 0.82

¶ Conclusion

The goal of reaching a 0.25 MoS is therefore attained