¶ Introduction

This document serves as "the spine" for our Bachelor Project on Anti Buckling Rings (ABR) Report - essentially, we outline the work done and link to the rest of the documentation, where the actual work is explained.

The Rocket Team's launch vehicle, Firehorn, was developed with modularity in mind. It was made so that each bay (Pressurant, Avionics, Engine) could be split into different modules, and then reconnected with couplers. In addition, "Modular Part Systems" were developped - essentially, a generalized component for all modules where sub systems can mount their parts to the structure.

These requirements yielded a design composed of 2 main parts:

- Couplers: aluminum pieces designed to hold flight loads and connect modules togehter

- Rods: CFRP rods designed to hold the flight loads across the length of the rocket, forming the "height" of modules

With thin long rods holding the engine's compression load, a critical failure mode was considered: buckling. To stop this, Anti Buckling Rings (ABR) were designed: essentially a ring surrounding the rods, "keeping them together" and increasing the critical load before which buckling occurs. This is where our bachelor project comes into play.

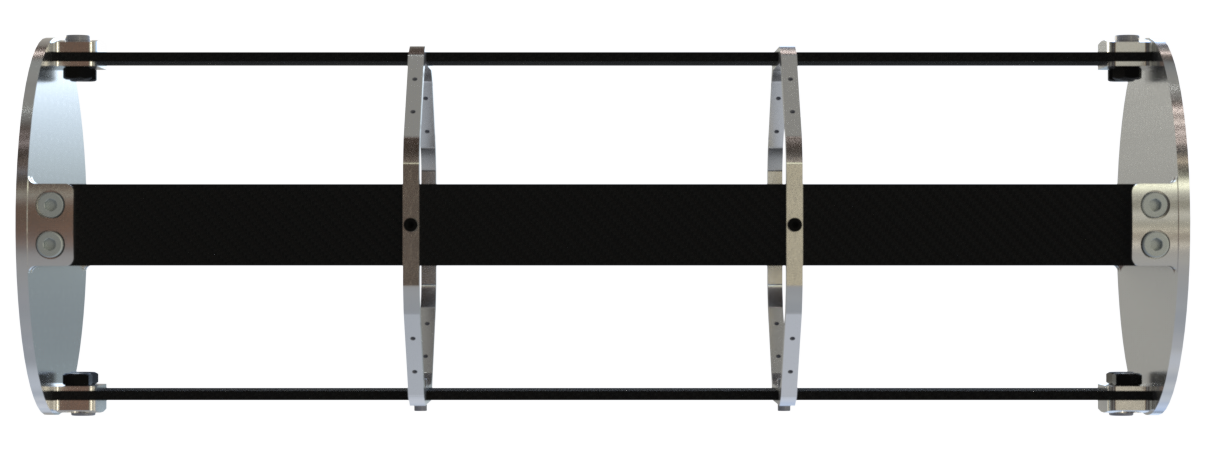

Here, the pressurant bay:

Originally, our project's direction was quite clear: optimize the design of anti buckling rings by exploring new materials and new geometries, with a specific focus on composites and carbon fiber. The objective was to go through design, analysis, manufacturing, and testing phases.

At our Preliminary Design Review, we were tasked with scaling down the anti buckling ring development, where, instead of manufacturing full scale rings, we would make small ones to validate the simulations, so that if the improved designs were worth it, we would then allocate the budget to manufacturing at a different time. We were also given the task of performing Dynamical Analyses for the first time in the Rocket Team's history, the objective being to develop this capacity within the Rocket Team's members, and to have another point of comparison between the Anti Buckling Rings.

We approached these tasks in 3 main phases:

- Initial Design Process: the initial research, design, and analysis phase where we got acquainted with the material available to us (most notably Florent Piton and Vianney Jacob's Semester Project designing the original Anti Buckling Rings) and started working - this was mostly done before the Preliminary Design Review in Week 8.

The next two phases were done concurrently, with Rafael and Joaquin focusing on manufacturing and testing, and Pedro focusing on dynamical analysis. - Manufacturing and Testing: preparing and executing the process of making Anti Buckling Rings, then preparing the tests to validate our simulations

- Dynamical Analyses: performing various dynamical analyses to learn how to do them and continue comparing our different designs

¶ Initial Design Process

Once we had our initial designs, we started the analysis work on Ansys. Before the PDR, 3 analyses were performed:

- COPV Analysis: [INSERT LINK PLS] as part of the Bachelor Project, we were tasked with analyzing the effect of the load applied by the COPV's weight on the Anti Buckling Rings.

- "Simplification" Analysis: [INSERT LINK PLS] we believed we could use the simulations on the aluminum anti buckling rings executed in a previous project (Aluminum ABR Analysis) to find the forces experienced by the ABRs, and consequently only simulate the rings, not the entire assemblies. Unfortunately, this was unsuccesful.

- Eigenvalue Buckling Analysis: the core of our analysis, where we found the "load factors" (multiplication factor of the current load before a buckling mode occurs) of our composite ABRs, allowing us to compare our designs to the previous aluminum design.

The conclusion of these analyses, surprisingly and disappoitingly, was that our composite ABR designs had a worse performance to mass ratio than the aluminum ones.

¶ Manufacturing and Testing

¶ Dynamical Analysis

After our Preliminary Design Review (PDR), we started dynamical analyis. The goal was: educational for the Rocket Team, to analyze the engine bay's performance under dynamical load, and to continue comparing our ABR designs.

Initially, we started by performing analysis on the Pressurant Bay, the same bay on which we had worked on for the eigenvalue buckling analyses. This analysis was mostly preliminary