¶ title: 2023_ST_PP_F01_Coaxial_Tanks

description: Link: https://rocket-team.epfl.ch/en/rocket_ss/structure/Nordend/2023_ST_PP_F01

published: true

date: 2025-05-21T19:09:19.880Z

tags:

editor: markdown

dateCreated: 2023-08-04T09:31:22.160Z

¶ title: 2023_ST_PP_F01_Coaxial_Tanks

description: Link: https://rocket-team.epfl.ch/en/rocket_ss/structure/Nordend/2023_ST_PP_F01

published: true

date: 2024-12-30T21:17:23.813Z

tags:

editor: markdown

dateCreated: 2023-08-04T09:31:22.160Z

¶ title: 2023_ST_PP_F01_Coaxial_Tanks

description: Link: https://rocket-team.epfl.ch/en/rocket_ss/structure/Nordend/2023_ST_PP_F01

published: true

date: 2023-12-01T02:40:10.288Z

tags:

editor: markdown

dateCreated: 2023-08-04T09:31:22.160Z

¶ Coaxial Tanks Production Procedure

¶ Table of Contents

¶ 1. Introduction

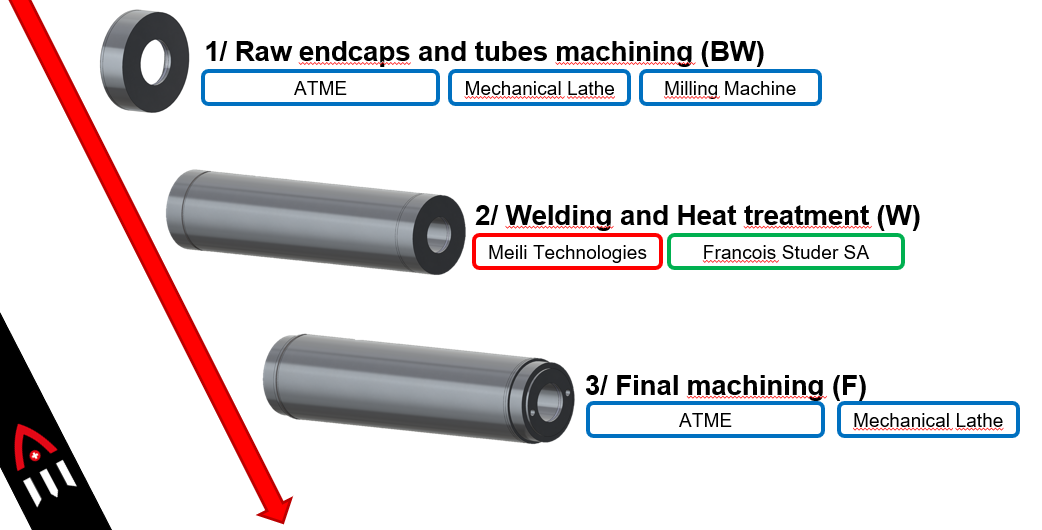

The coaxial tanks of Nordend are a complicated and flight critical system, extensive design collaboration was done between the ERT and different workshops (ATME - Machining, Francois Studer SA - Annealing, Meili Technologies - Welding) to mitigate manufacturing difficulties.

¶ 2. Reference Documents

| Doc. ID | Ref |

|---|---|

| Tanks TN | Tanks Technical Note |

| Tanks TRP | Tanks Test Report and Procedure |

| Coupler TN | Coupler Technical Notes |

¶ 3. Definitions and Abbreviations

| --- | --- |

| EXT | External Tank |

| INT | Internal Tank |

¶ 4. Production Description

¶ 4.1 Description

The coaxial tanks are split in two distinct tanks : an internal tank, and an external one.

In 2023, two set of coaxial tanks were produced, a test set and a flight set, identical in all aspect. They were named according to their production quality.

In this document we will focus only on the production of one set of coaxial tanks.

¶ 4.3 Parts Lifecycle and States

The parts being subjected to a long production cycle (machined, welded, annealed, and then machined again), a nomenclature was created to follow the part's state.

Coaxial Tank production timeline summary, extracted from Nordend's CDR, deadlines aren't mentionned for clarity

This is the expected timeline, however due to weld defects our tanks were leaking, leading to additionnal welding operations after the Final state (F), detailed under the following Tanks Test Report and Procedure

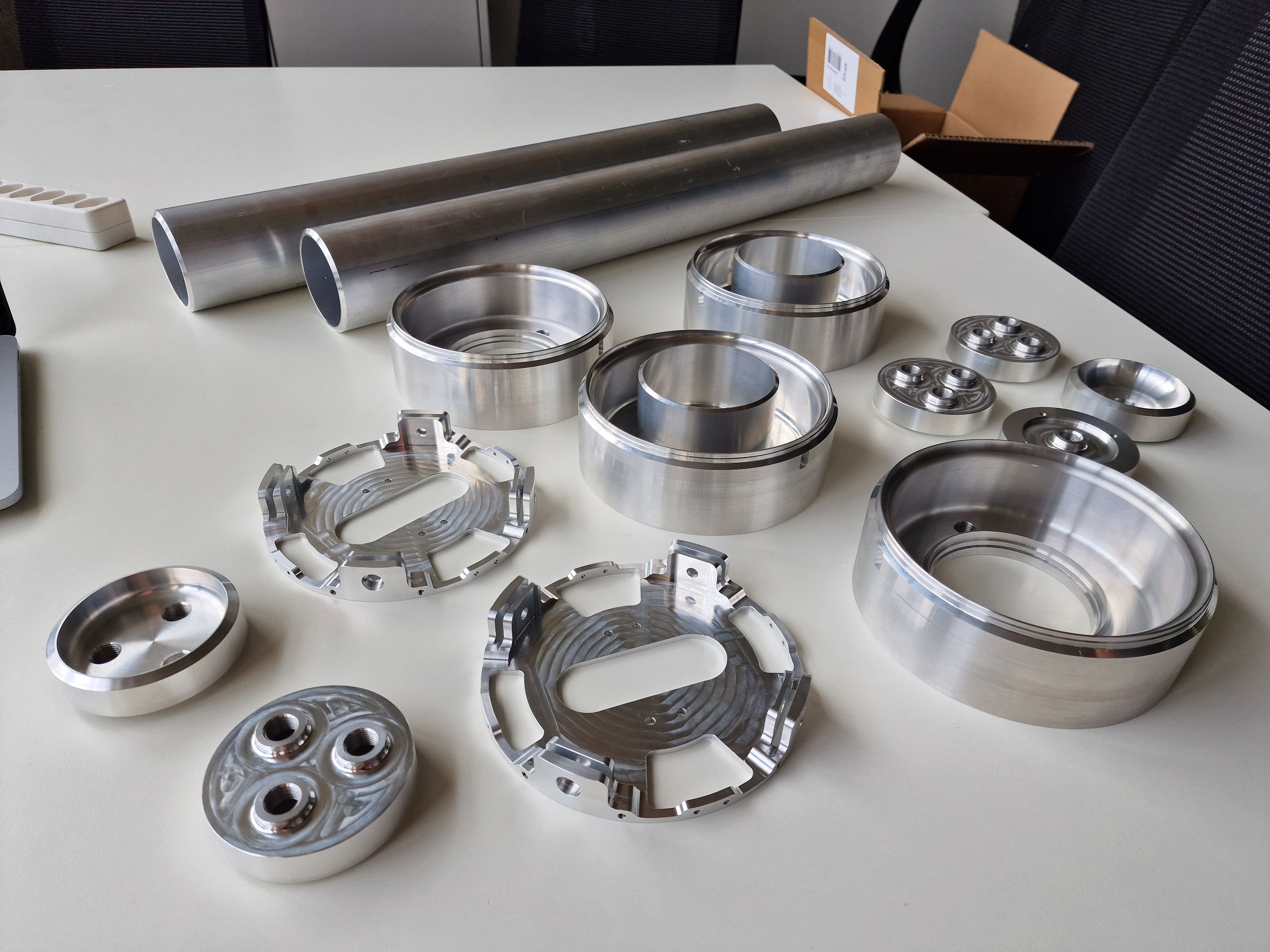

Before starting their production cycle, the parts are in their raw material state.

Raw material was bought :

Thyssenkrupp :

- 6082 T6 raw material (160 [mm] diameter)

- 6082 T6 raw material (125 [mm] diameter)

Alcobra.de / Alumeco.de :

- 6082 T6 tube (80 [mm] external diameter, 5 [mm] thickness)

- 6082 T6 tube (90 [mm] external diameter, 5 [mm] thickness)

- 6082 T6 tube (160 [mm] external diameter, 5 [mm] thickness)

Tubes in their raw state, on their way to the ATME

Finding tubes that fit together with the right material was really hard, and should be considered early in the tank developpement

The first step is the machining of the raw endcaps and tubes by ATME, known as the before welding state.

- Final state (F) of the whole system was already settled at this stage.

- Corresponding batch at ATME is 02.3

- Extensive collaboration was done with Meili Technologies to find the weld chamfers and overall geometries.

Most of the BW state parts

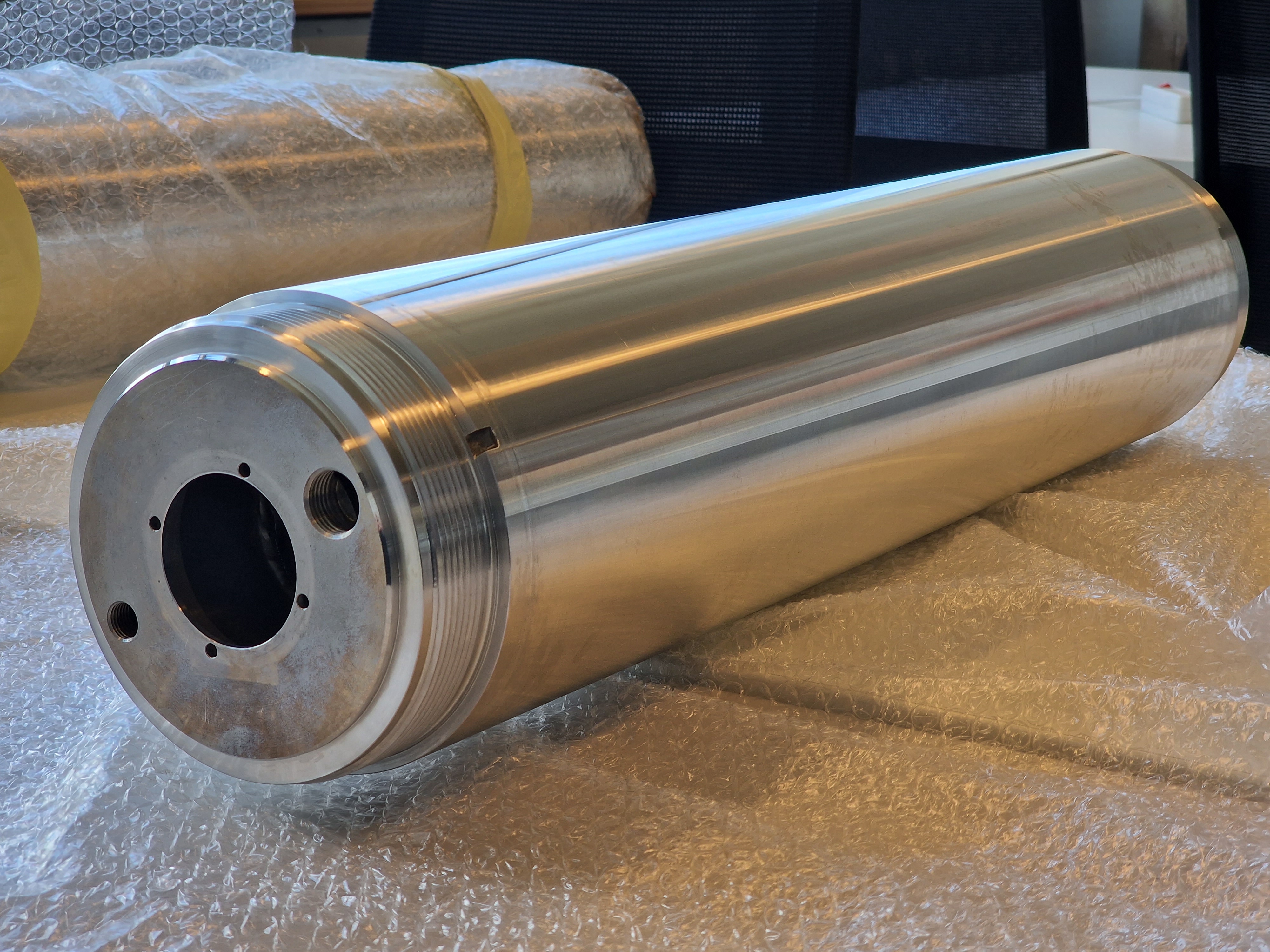

The parts are welded by Meili Technologies at their facility, the tanks are then starting too look like such !

- Great care was taken to ensure the alignement of the endcaps relative to one another, since after welding we can't rotate them anymore !

- Parts in their welded state were sent to Francois Studer SA to do an annealing (T6) to restore the aluminium properties after the welding process.

A closeup of the external tank in it's Welded state

Damages can occur during these operations, don't hesitate to take some pictures before and after.

The raw tanks are machined by ATME to reduce their external diameter and machine the threaded coupling solution.

- Corresponding batch at ATME is 03

- ATME machined additionnal parts in order to mount the tanks to the laythe.

An external tank in it's final state

This is the expected final state, however due to weld defects our tanks were leaking, leading to additionnal weld operations, detailed under the following Tanks Test Report and Procedure

¶ 4.2 Parts List

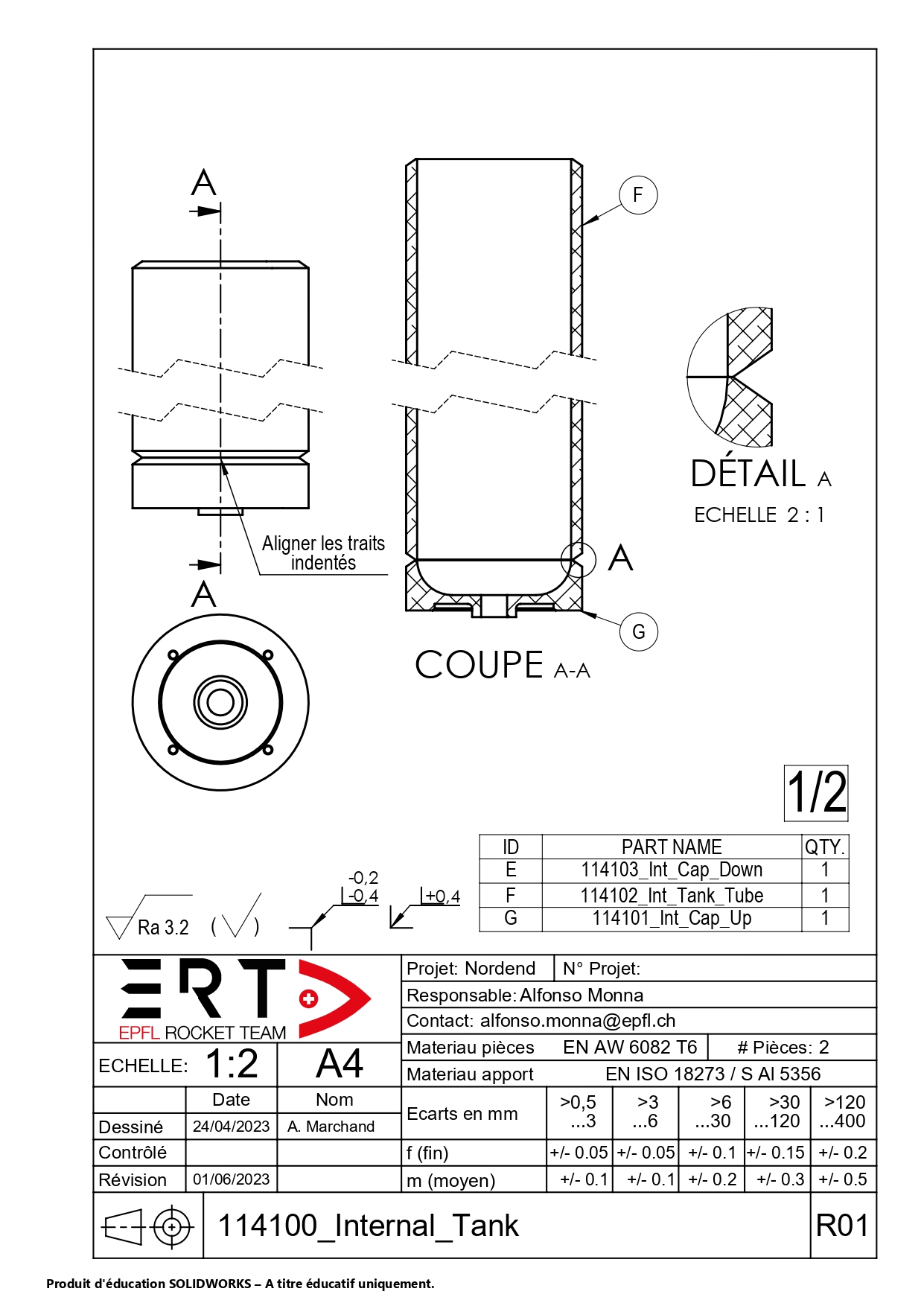

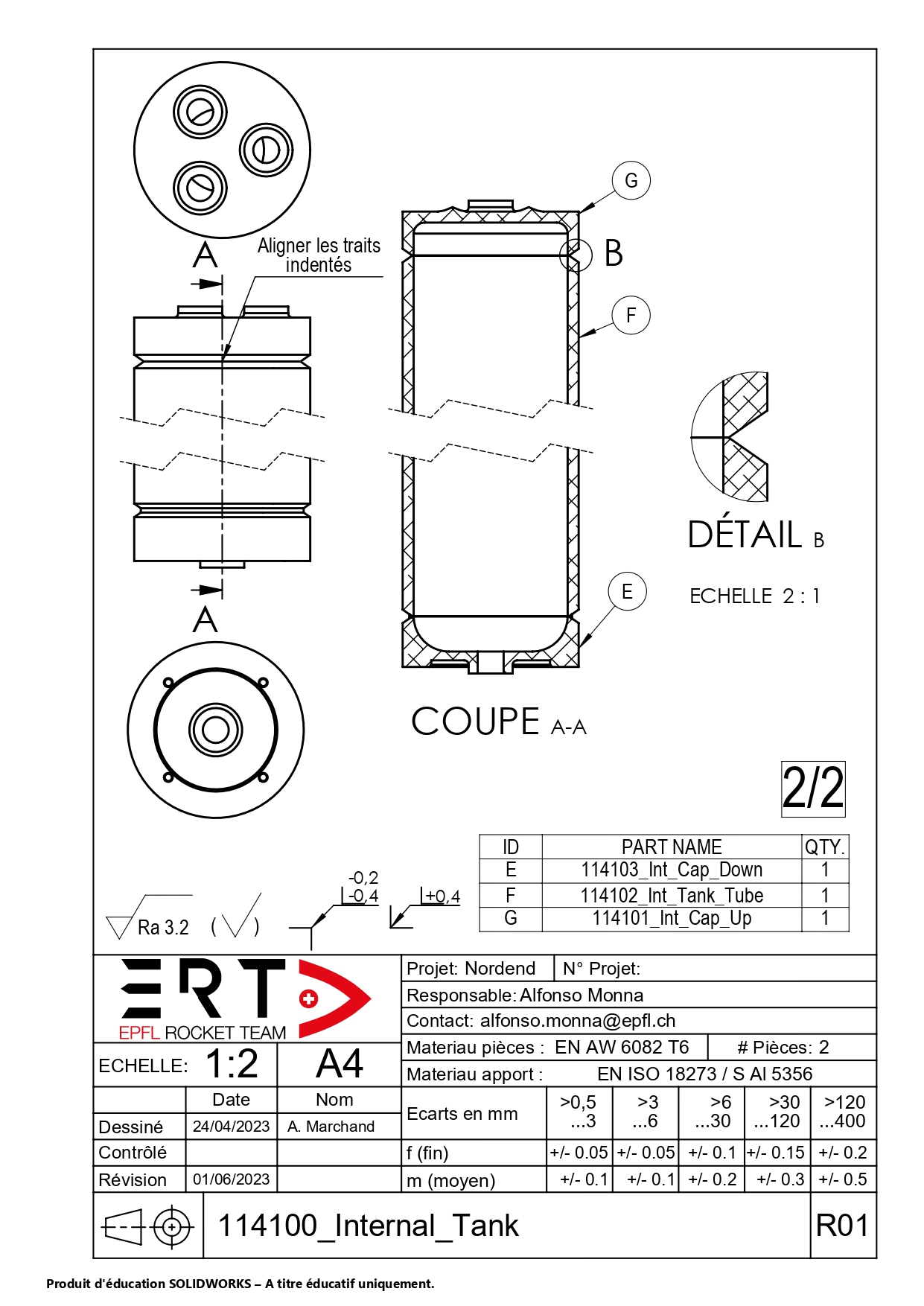

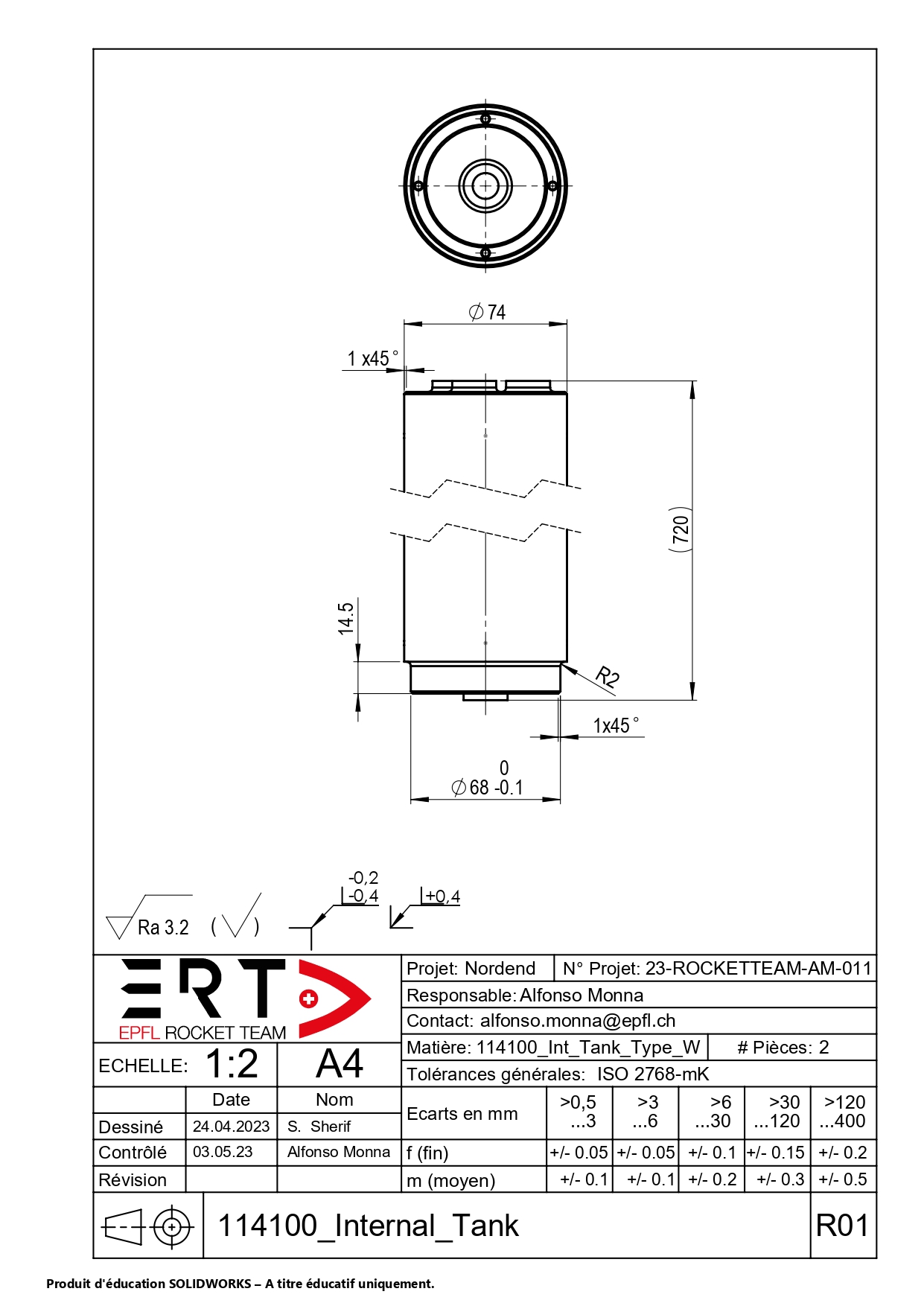

The following table recaps all the parts constituting the final internal tank :

| Description | Part Ref | # Units |

|---|---|---|

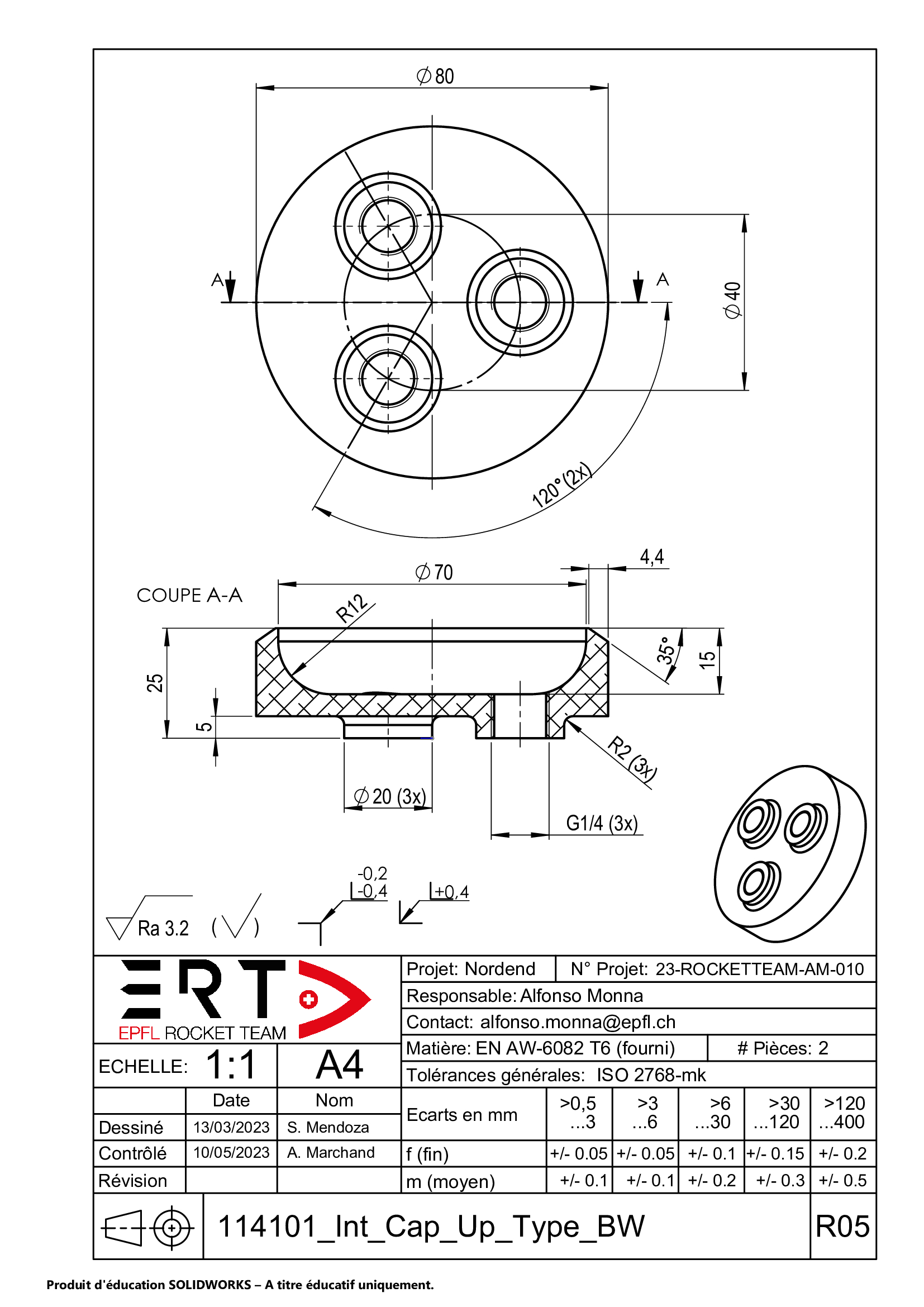

| Internal Cap Up | 114101_Int_Cap_Up | 1 |

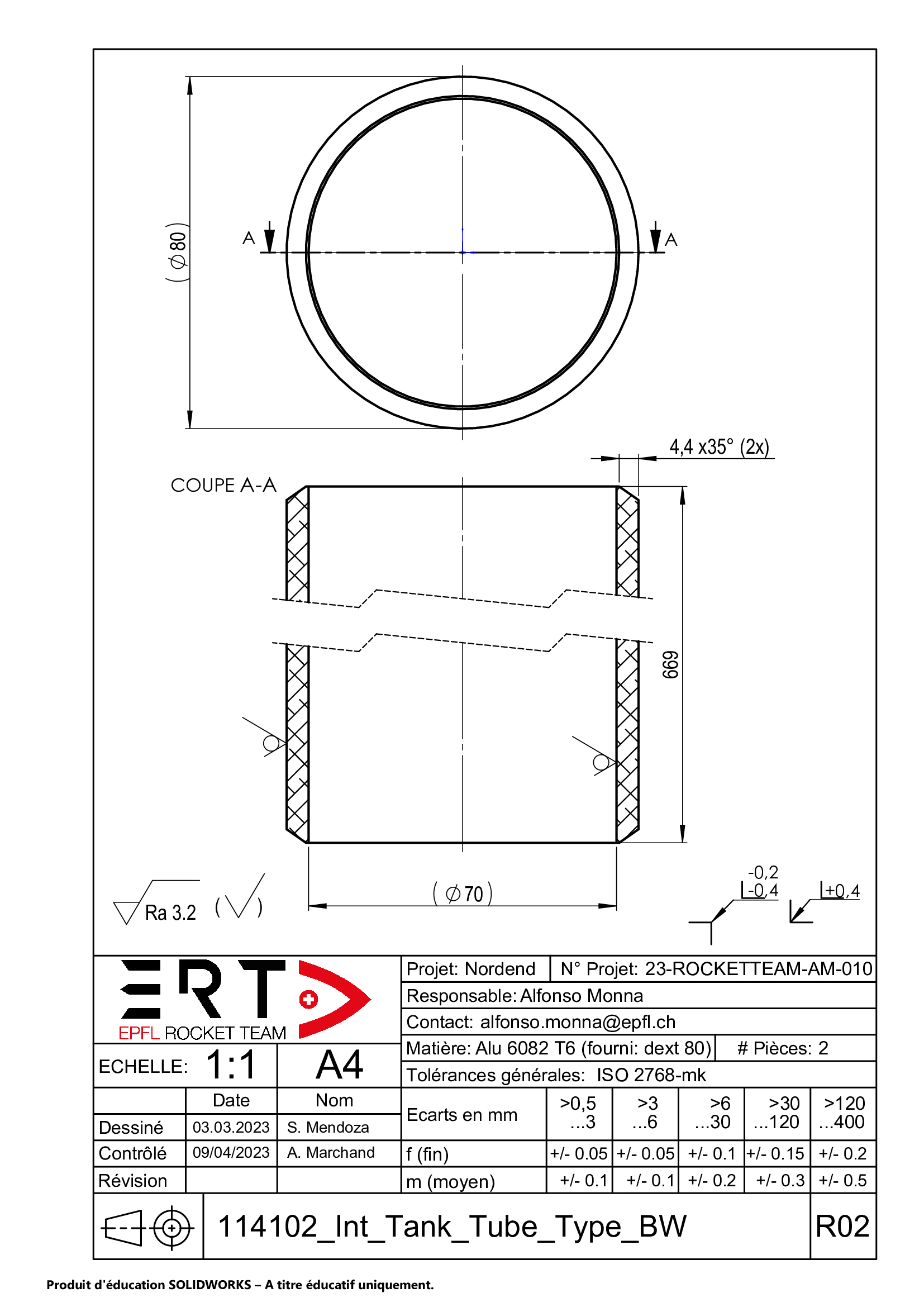

| Internal Tube | 114102_Int_Tank_Tube | 1 |

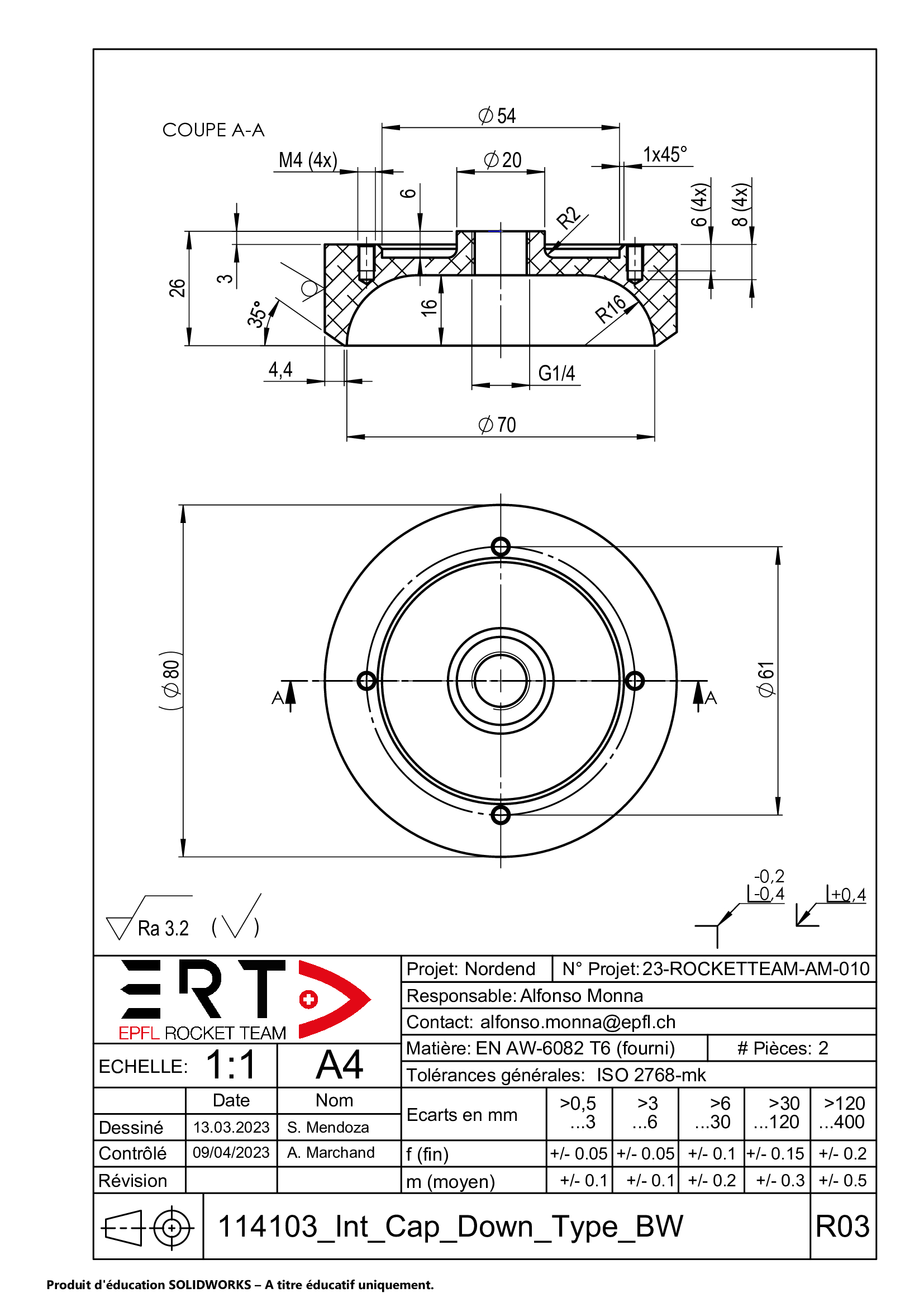

| Internal Cap Down | 114103_Int_Cap_Down | 1 |

A closeup of the internal cap up, in it's BW state

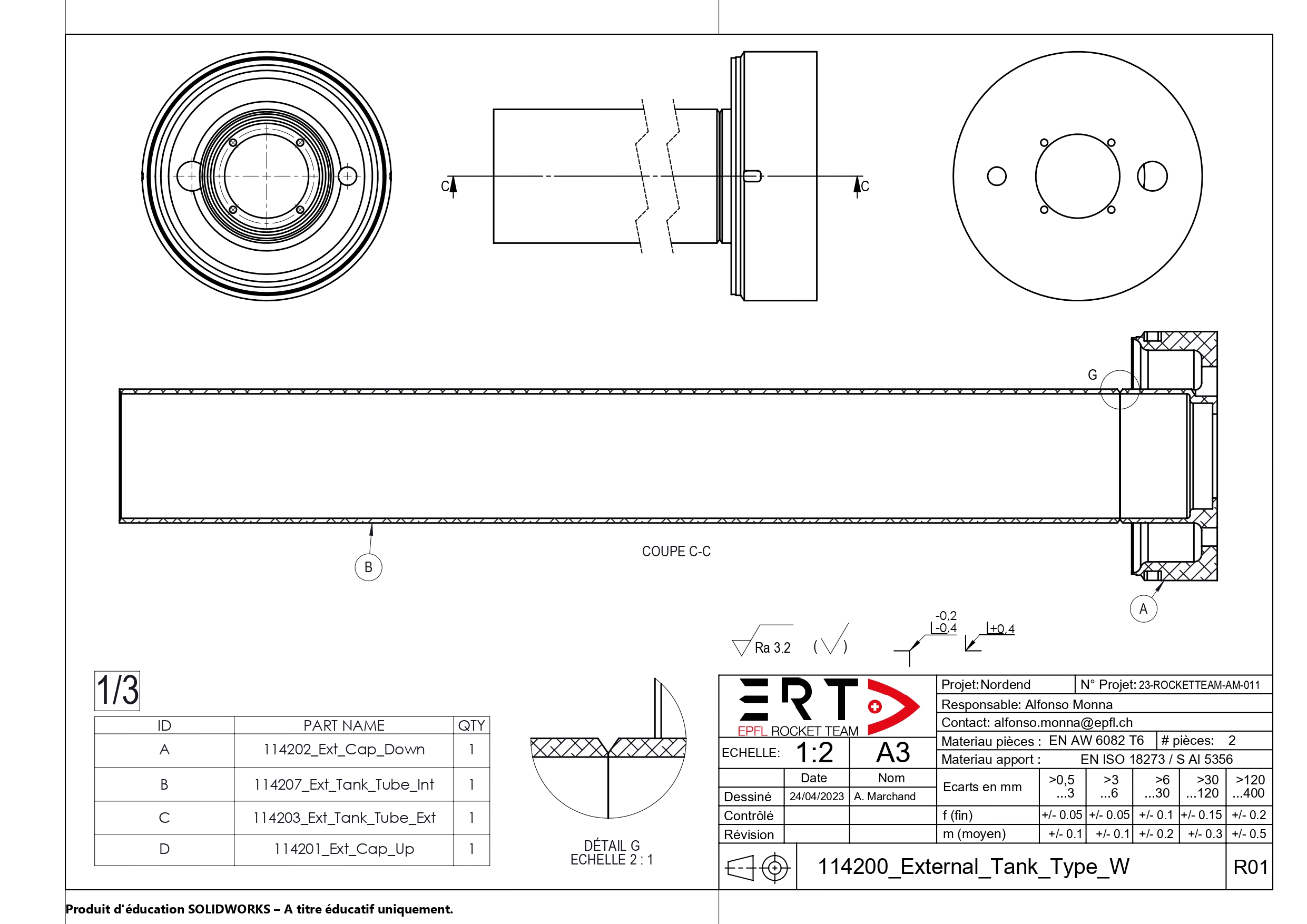

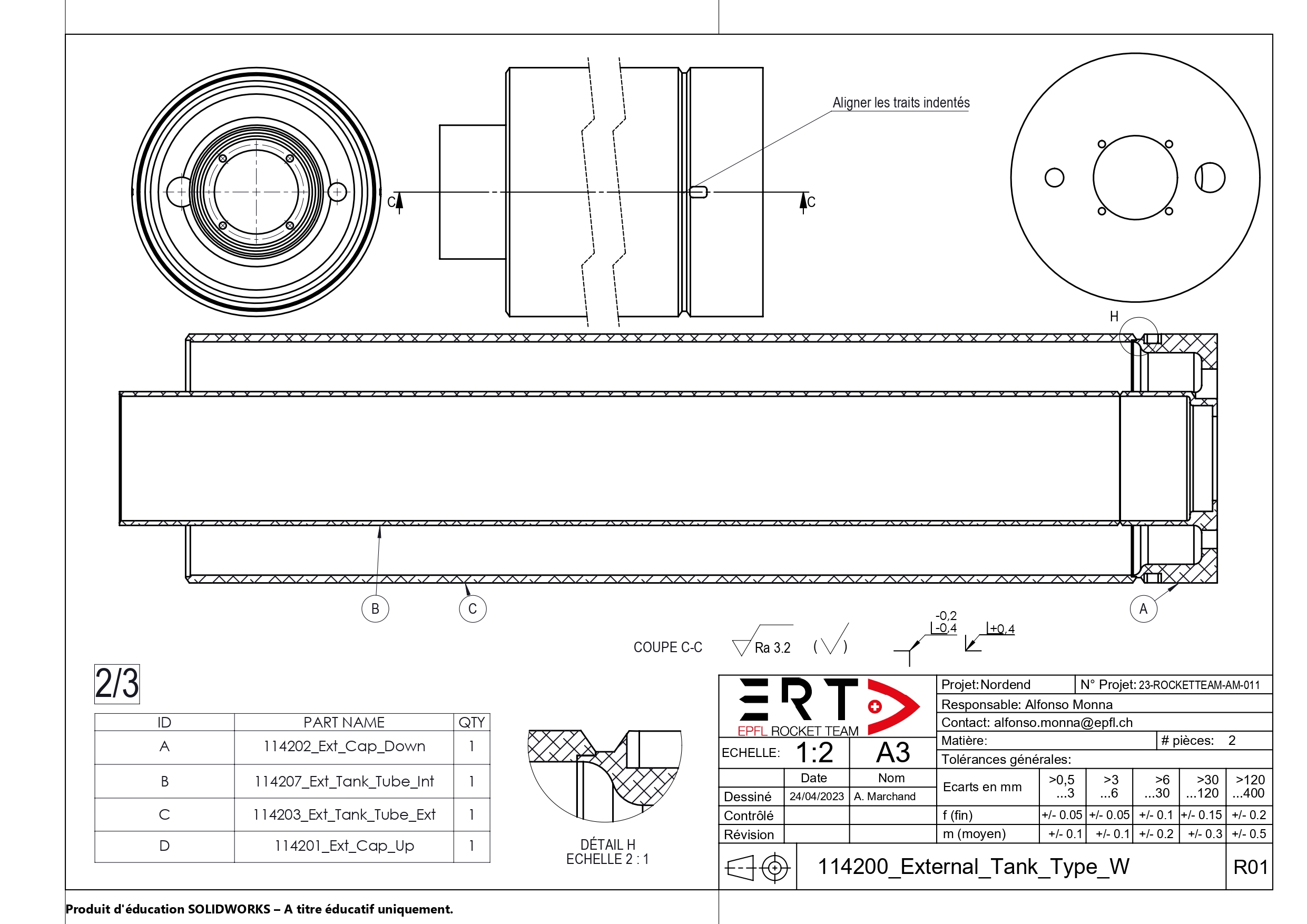

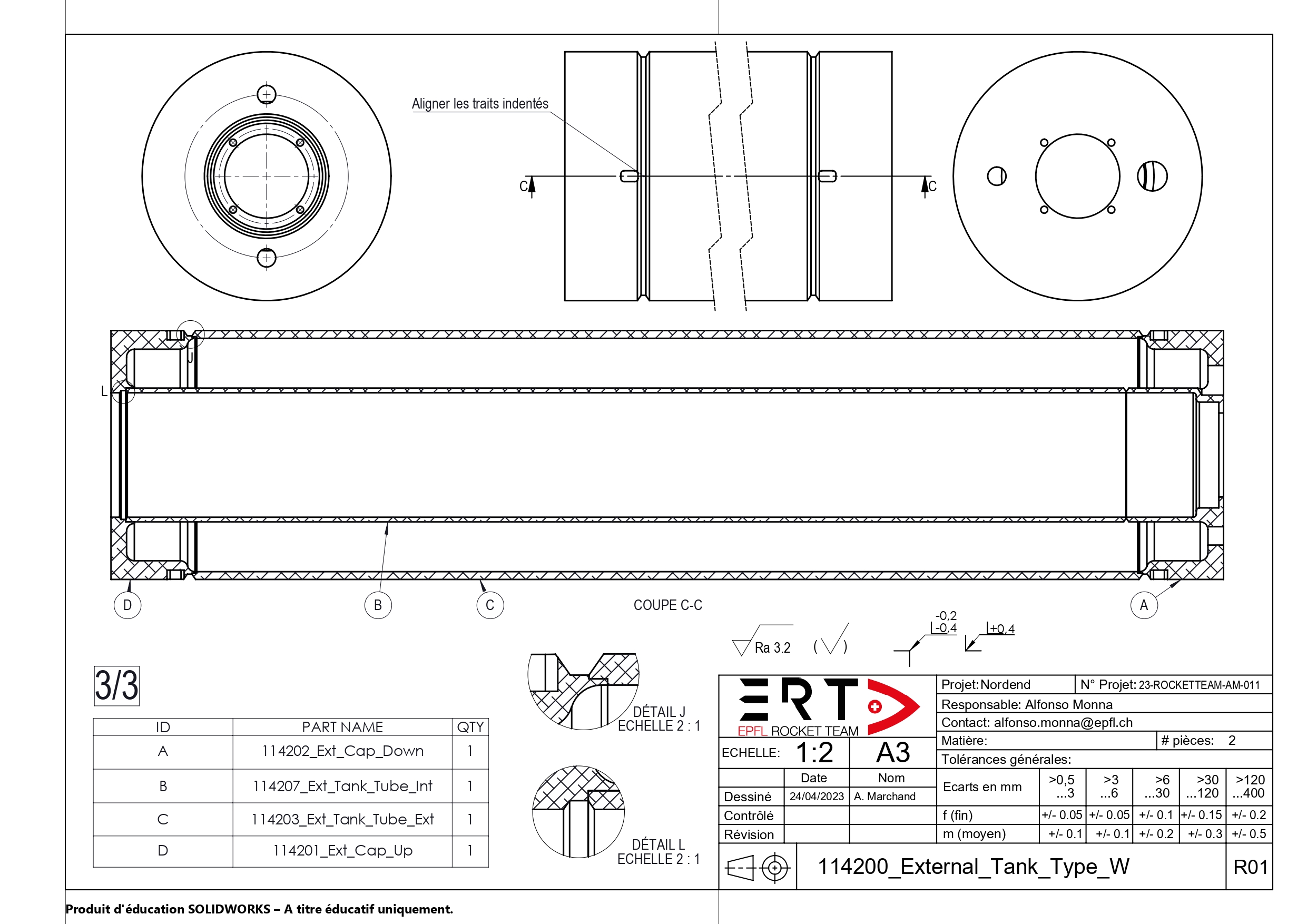

The following table recaps all the parts constituting the final external tank :

| Description | Part Ref | # Units |

|---|---|---|

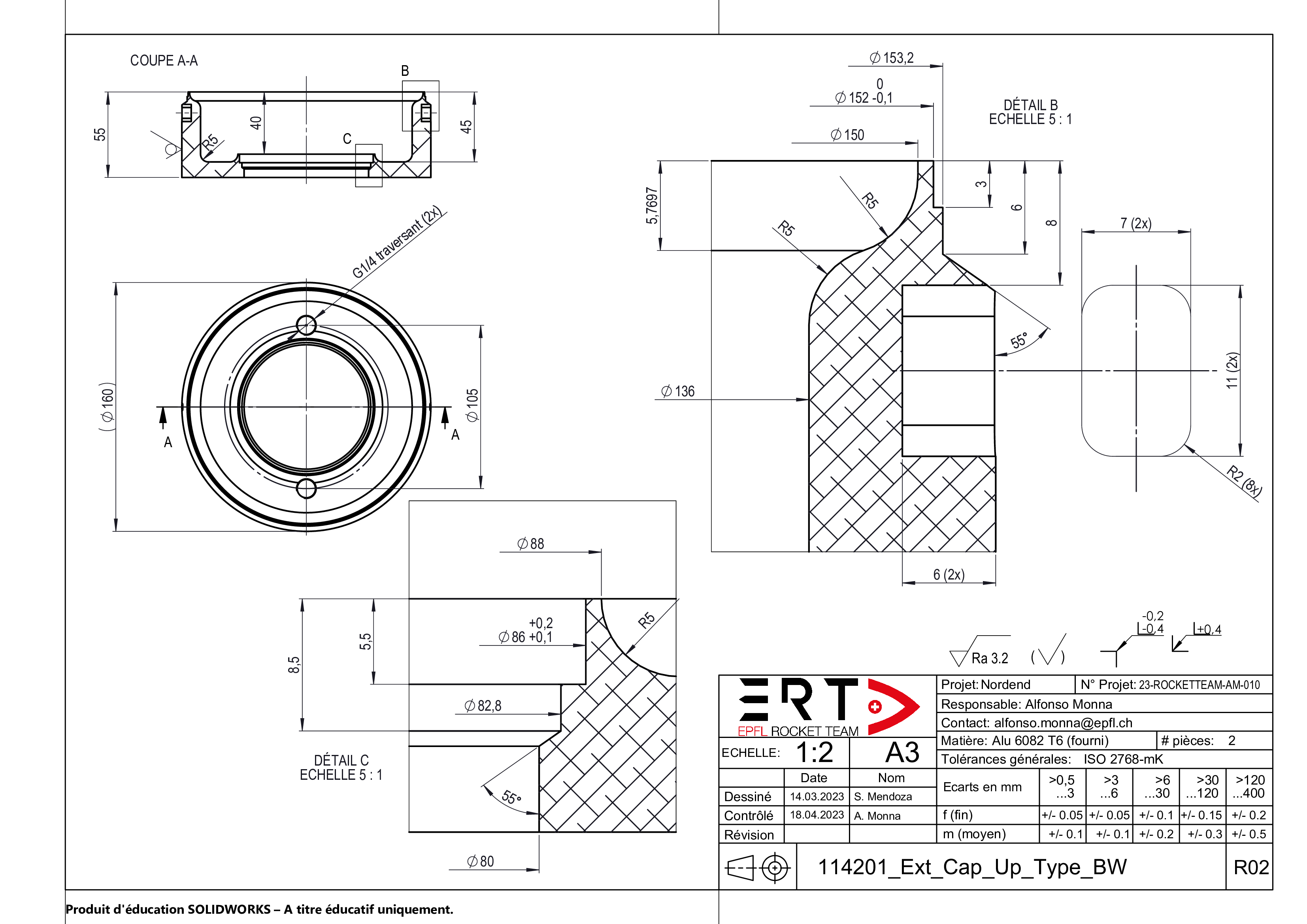

| External Cap Up | 114201_Ext_Cap_Up | 1 |

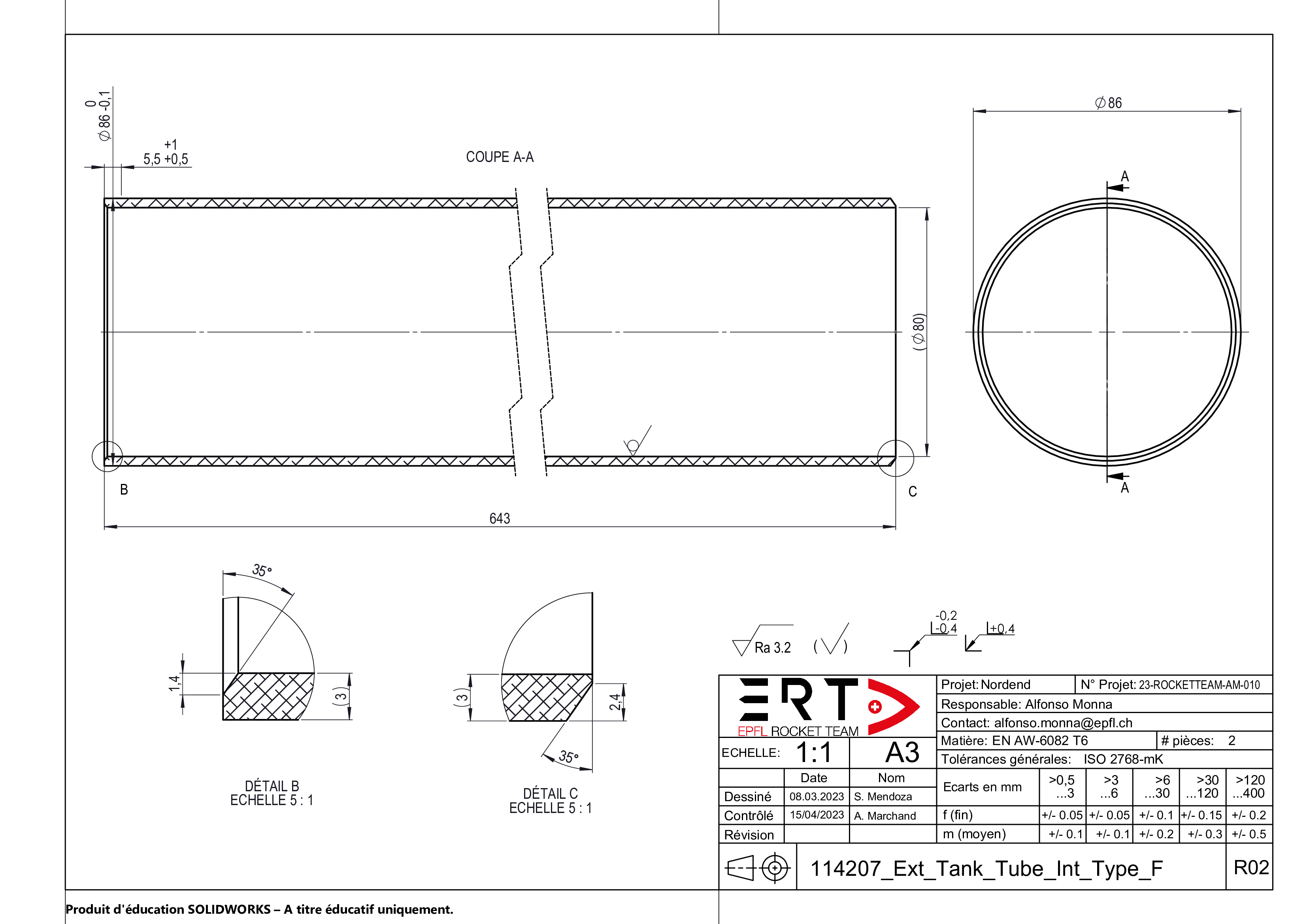

| External Tube Internal | 114207_Ext_Tank_Tube_Int | 1 |

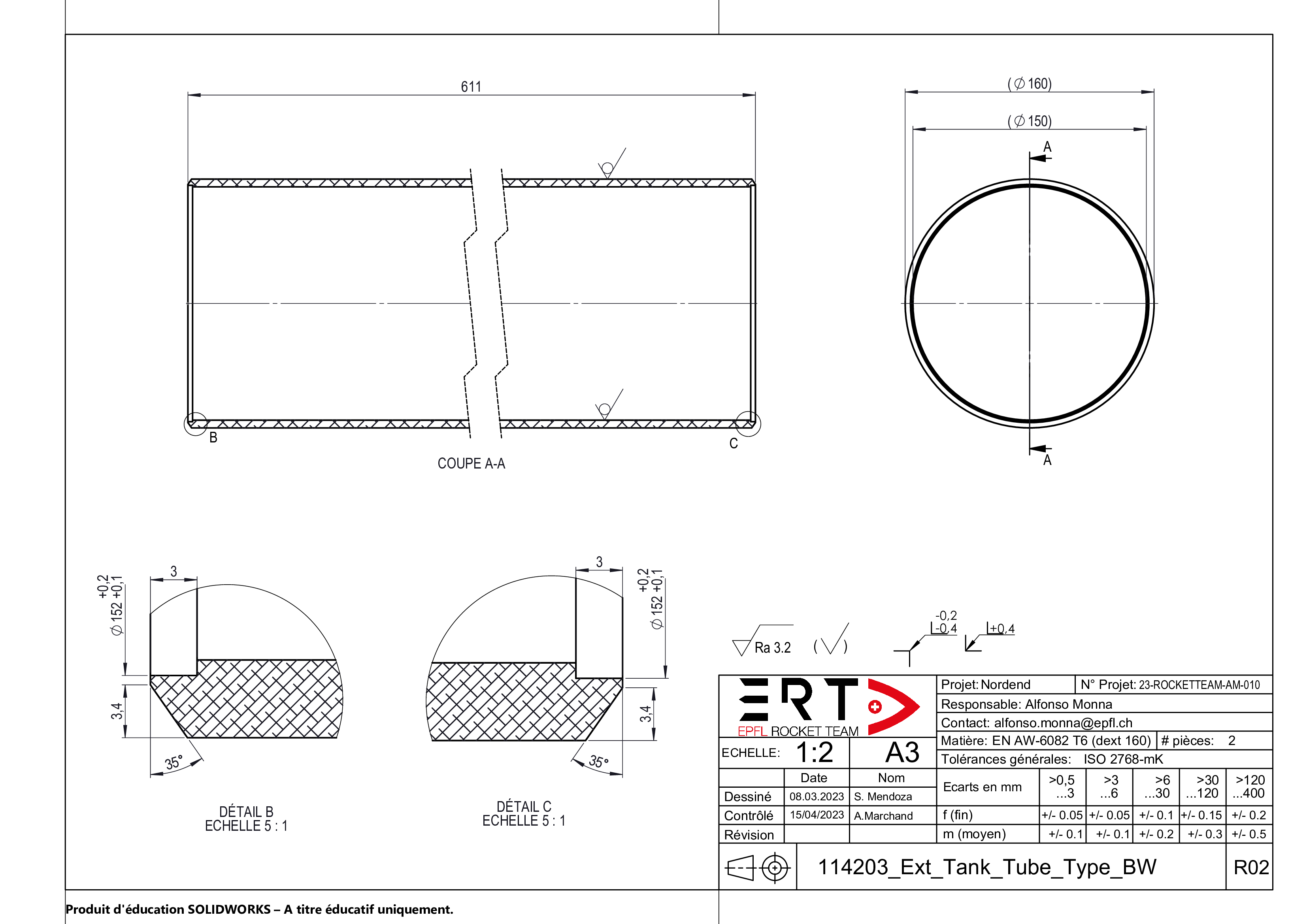

| External Tube External | 114203_Ext_Tank_Tube_Ext | 1 |

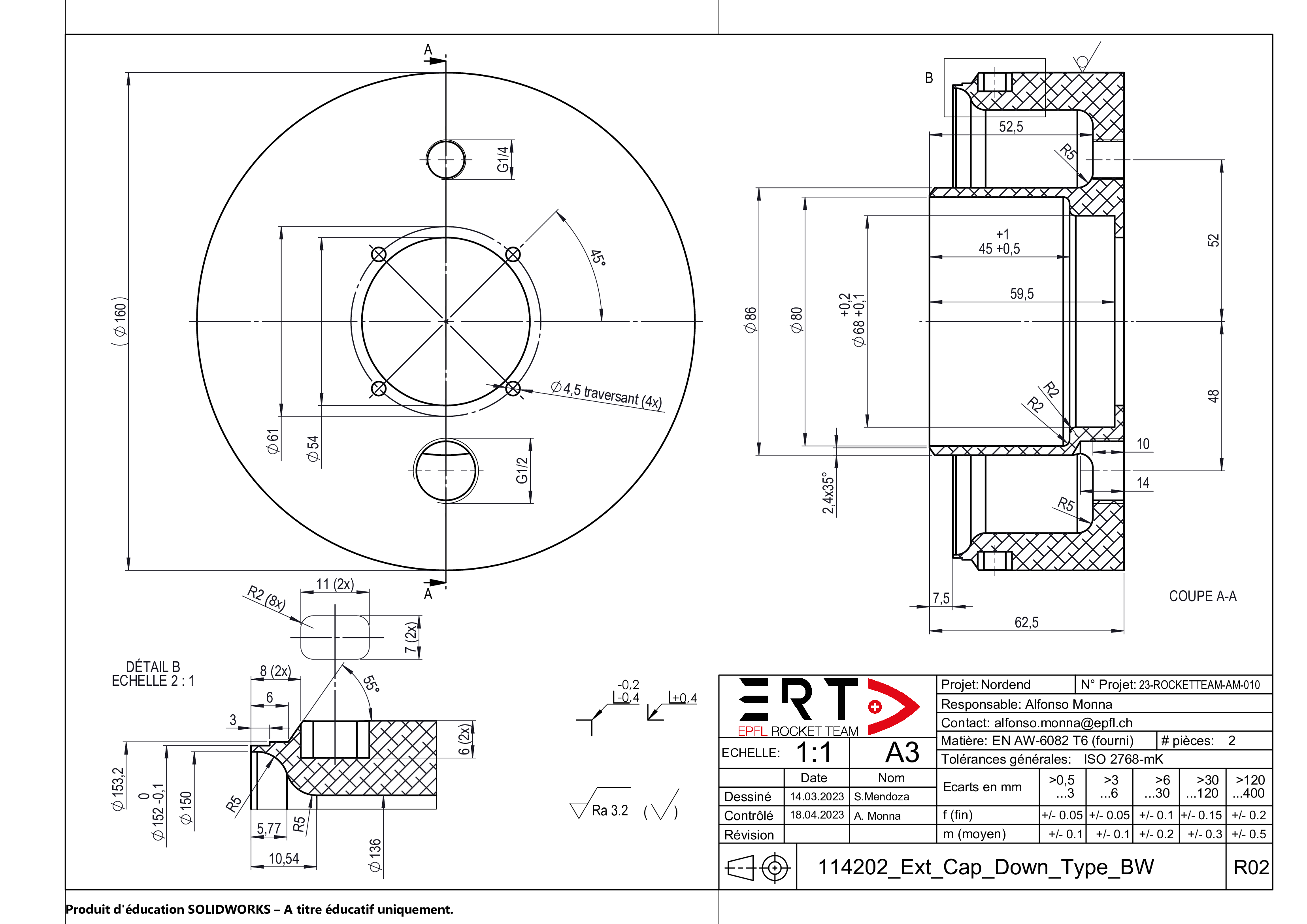

| External Cap Down | 114202_Ext_Cap_Down | 1 |

A closeup of the external cap down, in it's BW state

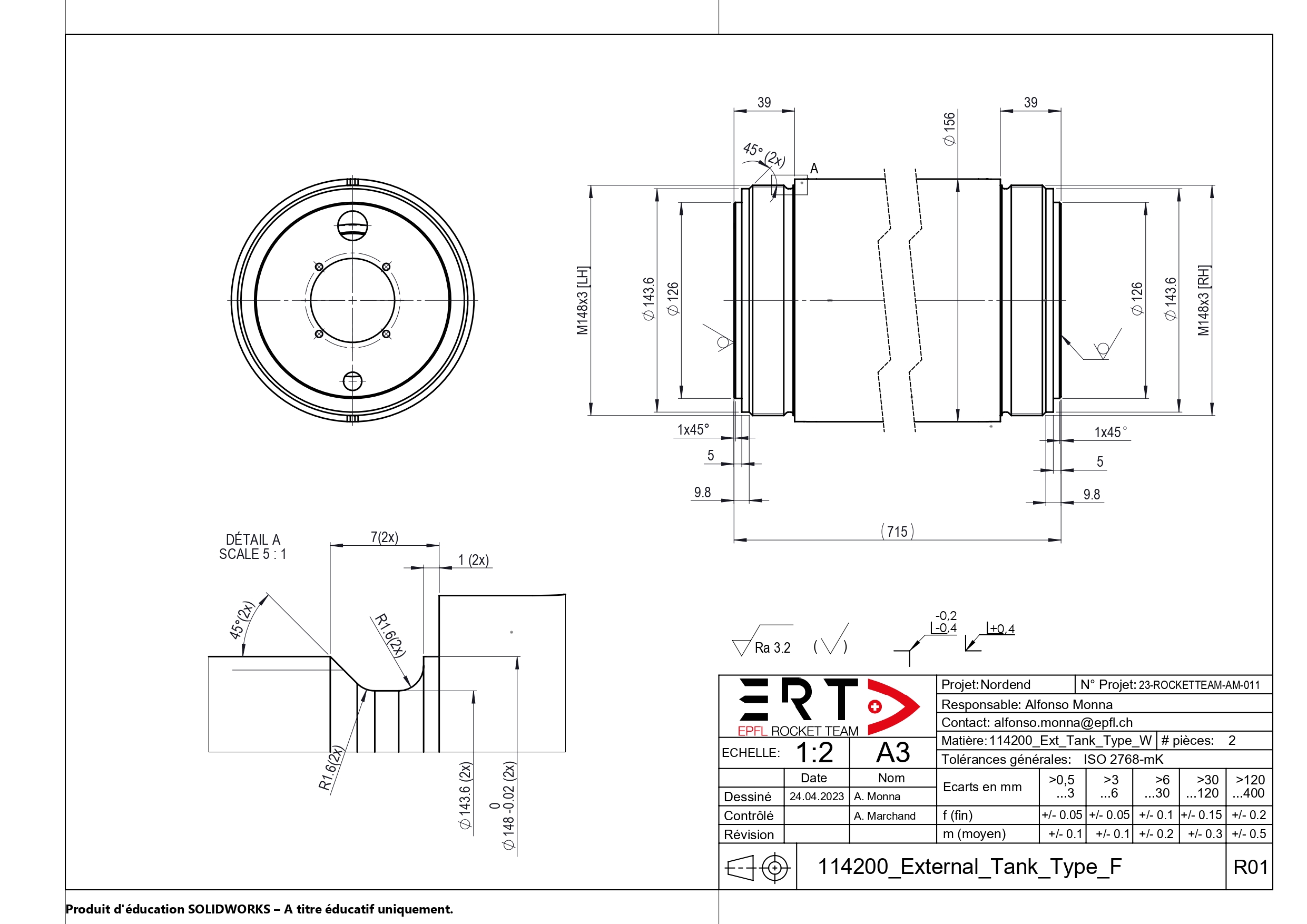

¶ 4.3 Technical drawings

The technical drawings are also available in pdfs under the following drive folder.

¶ 4.3.1. Before Welding (BW)

¶ 4.3.2. Welded (W)

The welded technical drawings indicates the welding sequence. For details on the weld cords, check the Tanks Technical Note

¶ 4.3.3. Final (F)

¶ 5. Cost Estimation

The following table gather the estimated cost of each workshop. Exact spending of the structure subsystem can be found in the Nordend Master Budgets

| Furnisher / Workshop | Type | Cost Estimation |

|---|---|---|

| Thyssenkrupp | Raw 6082 T6 in bulk | CHF 1 286,46 |

| Alumeco | 6082 T6 tubes | CHF 813,09 |

| ATME | Machining | CHF 3500 |

| Meili Technologies | Welding | CHF 0 (sponsored) |

| Francois Studer SA | Annealing | CHF 0 (sponsored) |

| TOTAL | CHF 5600 |

¶ 6. Conclusion

Nordend tanks production is heavily reliant on external workshops, allowing for overall higher production quality but making the overall operation quite complex.

It's aluminium nature made it difficult to weld, steel conventionnal tanks are recommended for future cryogenic rockets. If possible, try to do test parts before the final ones, to validate the production techniques.

Collaboration with the wokshops proved to be essential for the timeline management as well as the feasability of the overall system. Meetings with the chosen workshops should start as early as possible in the design process.