¶ 2025_C_ST_ABR_TSP

¶ Introduction

¶ Purpose, Objective and Scope

¶ Introduction

¶ Purpose

This document is prepared to define and guide the structral testing of the small scale ABRs intended to validate the possible new carbon fiber design made during the bachelor project concerning the ABRs. The goal of this test is to validate the computer simulation of the new designs of ABRs through the deformation and maximum stress of the new parts.

This document provides a test specification and a possible test procedure, as the actual test procedure needs to be first validated by the supervisor of the traction machines.

¶ Objective

As stated above, the main objective of this test is to verify the results of the simulation on the ABRs made with Ansys ACP. The verification includes noting both the differences of maximum deformation of the parts as well as the maximum stress that these parts can support. It will be then determined the influence of the manufacture on these results to then conclude on the validity of the simulations.

¶ Test Specification Section

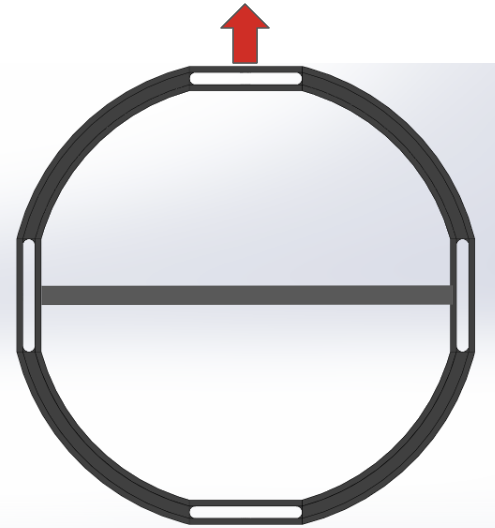

We will test the carbon fiber ABRs made during the bachelor project by applying a gradual force on one of its straight parts, while at the same time blocking any "buckling" of the two adjacent straight parts by linking them with a substantially resistant rod; the ABR is held down by blocking the final straight part to the machine directly. The force and the deformation of the part is directly given by the traction machine itself ensuring precise measurements.

Here is a diagram example of the test:

¶ Test Procedure

¶ Tools and Instruments Required

| Tool / Instrument | Purpose |

|---|---|

| Traction machine | Measuring and applying the deformation and force |

| ABRs (at least 3 for a fair test) | Part we want to measure |

| CFRP/metal rod | Blocking the two perpendicular straight faces of the ABR |

| Traction machine equipment | Seting up the machine and maintaining the ABR in place |

¶ Step-by-Step Procedure

¶ Before the Test

-

Prepare the test specimen

- Visually inspect the ABR for possible damage during demoulding, and verify that the spacers are correctly held in place with resine

-

Seting the machine

- With the help of the representative for the traction machine verify that the software part of the machine is correctly done

- Then setup the hardware of the machine making sure the right cables are properly connected

- Then with the help of the representative setup the ABR on the machine enuring it is properly fixed

-

Ensure safety

- Make sure the safety mode on the machine is on, wear protective glasses in the enventuality of debris from the breaking of the ABR

- It is also mandatory that multiple people are present during the tests in the eventuality of an accident

¶ After the Test

-

Post-test visual inspection

- Examine the part to ensure that the test concluded on a rupture

-

Document results

- Rcover all the test files from the traction machine through the specific procedure provided during the training

-

Clean up

- Clean up the traction machine for all the carbon fiber debris, as well as all the equipment used during testing

¶ Test Specification

¶ Pass/Fail Criteria

The ABRs are consdered to have passed the tests if after having reviewed the results of the maximum deformation an stress, these values are sufficiently close to the simulation. It is important to take into account the difficulties that occured durng the manufacturing of the small scale ABRs which have an impact on the final parts used during the tests.

¶ Test Procedure

¶ Test Safety

¶ Main Risks

| Safety Concern | Probability | Impact | Severity | Mitigation | Post-Mitigation Probability | Post-Mitigation Impact | Post-Mitigation Severity |

|---|---|---|---|---|---|---|---|

| ABR breaking in an "explosive" way leading to carbon micropieces dispersing | Medium | health hazard | Medium | Durng the test prepare a safety glass to protect the users and the surroundings | Low | Low | Low |

| Traction machine crushing the hand of the user | Low | health hazard | Very High | follow the safety procedures, have multiple users in the room, don't approach the machine during testing | Very Low | low | Very high |

| ABR damage during insertion | Low | Test invalid | Medium | Do the setup with the traction machine representative | Very Low | Low | Low |