¶ Introduction

¶ Purpose, Objective and Scope

The objective of this Design Definition File (DDF) is to go over the computations done on the last version of the Hopper Structure to make sure it complies with the requirements of the vehicle. It will not go into the design choices of each sub assemblies. This is done in summary in the DJF (Design Justification File) of the main structure or in detail in the DJF of the specific sub assemblies. All of these files can be found here.

¶ Definitions and Abbreviations

- ST : Structure

- AV : Avionics

- PR : Propulsion

- LV : Launch Vehicle

- DOF : Degree of Freedom

- CDR : Critical Design Review

- BOM : Bill of Material

¶ Applicable and Reference Documents

- Design Requirement List (2024 DRL)

- High-Level Interface Management (2024 HLIM)

- Bill of Material and production plan of the Hopper (2024 BOM)

- Critical Design Review (CDR) of the Hopper on the 13.05.2024

- Flexure-based gimbal with high support stiffness for rocket thrust vector control (IAC2023)

- Compliant mechanism Simon Henein's thesis

¶ Requirements

Here are the requirements that apply to the design of the structural parts. The rest of the requirements can be found here.

-

2024_I_REQ_7

Total Dry Mass

The LV's total dry mass shall be [69'0000][±2'000]g. -

2024_I_REQ_9

Total Height

The LV's total height shall be [2'300][±200]mm. -

2024_I_REQ_11

Desert environment

The LV should satisfy the IP54 water and dust ingress standard (IP STD). -

2024_I_REQ_12

Temperature Range

The LV shall operate within the temperature range from [-10]°C to [50]°C. -

2024_I_REQ_14

Radial acceleration

The LV and all its components shall withstand [3.5]g of radial acceleration. -

2024_I_REQ_15

Axial acceleraion

The LV and all its components shall withstand [10]g of axial acceleration. -

2024_I_ST_REQ_1

Declaration of Purpose

The ST shall guarantee the structural integrity of the LV. -

2024_I_ST_REQ_2

Subsystems assembly

The ST shall guarantee that every LV's subsystem can be integrated to ensure the functionning of the LV. -

2024_I_ST_REQ_3

Assembly human needs

The assembly of the ST shall require at most [4] operators. -

2024_I_ST_REQ_4

Symmetry

Excluding propulsion elements, the ST shall be quadri-symmetric.

-

2024_I_ST_AVIONICS_BAY_REQ_1

Declaration of Purpose

The Avionics bay shall hold all the boards and antennas of the AV subsystem. -

2024_I_ST_AVIONICS_BAY_REQ_2

Avionics Bay - Avionics Interface

The AV Bay shall host the bards of the AV subsystem. -

2024_I_ST_AVIONICS_BAY_REQ_3

Avionics Bay - Upper Structure Interface

The AV Bay shall be directly mounted on top of the upper structure. -

2024_I_ST_AVIONICS_BAY_REQ_4

Avionics Bay Length Contribution

The AV Bay's length shall be at most [400]mm. -

2024_I_ST_AVIONICS_BAY_REQ_5 Avionics Bay Mass Contribution

The AV Bay's mass shall be at most [2'400]g. -

2024_I_ST_AVIONICS_BAY_REQ_6

Avionics Bay RF Considerations

The AV bay shall be designed to minimize RF interferences. -

2024_I_ST_AVIONICS_BAY_REQ_7

Avionics Bay Accessiblity

The AV Bay shall be designed so as to maximize the antennas's clearence. -

2024_I_ST_AVIONICS_BAY_REQ_8

Avionics Bay Axial Mass Distribution

The AV Bay's center of mass shall be no further that [10]mm from the LV's central axis.

-

2024_I_ST_UPPER_STRUCTURE_REQ_1

Declaration of Purpose

The Upper Structure shall host the propellant tanks. -

2024_I_ST_UPPER_STRUCTURE_REQ_2

Upper Structure Structural Elements

The Upper Structure's flight and pressure loads shall be born by the propellant tanks. -

2024_I_ST_UPPER_STRUCTURE_REQ_3

Upper Structure - Propulsion Interface

The Upper Structure shall host the Propulsion's "pressurization circuit" plumbing. -

2024_I_ST_UPPER_STRUCTURE_REQ_4

Upper Structure - Middle Structure Interface

The Upper Structure shall be mounted onto the middle structure. -

2024_I_ST_UPPER_STRUCTURE_REQ_5

Upper Structure Length Contribution

The Upper Structure's length shall be at most [760]mm. -

2024_I_ST_UPPER_STRUCTURE_REQ_6

Upper Structure Mass Contribution

Excluding propulsive elements, the Upper Structure's mass shall not exceed [6'200]g. -

2024_I_ST_UPPER_STRUCTURE_REQ_7

Upper Structure Axial Mass Distribution

The Upper Structure's center of mass shall be no further that [10]mm from the LV's central axis. -

2024_I_ST_UPPER_STRUCTURE_REQ_8

Upper Structure Accessiblity

The Upper Structure shall be mounted so as to be within arm's reach of any operator. -

2024_I_ST_UPPER_STRUCTURE_TANKS_REQ_1

Declaration of Purpose

The upper structure's tank shall be used as the on-board storage of propellant. -

2024_I_ST_UPPER_STRUCTURE_TANKS_REQ_2

Tanks Nominal Pressure

The propellant tank shall maintain a nominal pressure of [40][± 2]bar. -

2024_I_ST_UPPER_STRUCTURE_TANKS_REQ_3

Tanks Propellant Load

The tanks shall contain propellants for at [15]s-long mission.

-

2024_I_ST_MIDDLE_STRUCTURE_REQ_1

Middle Structure - Avionics Interface

The batteries shall be mounted onto the Middle Structure. -

2024_I_ST_MIDDLE_STRUCTURE_REQ_2

Middle Structure - FTS Interface The FTS shall be mounted onto the Middle Structure. -

2024_I_ST_MIDDLE_STRUCTURE_REQ_3

Middle Structure - Propulsion Interface

The COPV shall be mounted onto the Middle Structure. -

2024_I_ST_MIDDLE_STRUCTURE_REQ_4

Middle Structure - Propulsion Interface

The propulsion's "engine circuit" shall be mounted into the Middle Structure. -

2024_I_ST_MIDDLE_STRUCTURE_REQ_5

Middle Structure - Legs Interface

The legs shall be mounted on the Middle Structure. -

2024_I_ST_MIDDLE_STRUCTURE_REQ_6

Middle Structure Length Contribution

The Middle Structure's length shall be at most [680]mm. -

2024_I_ST_MIDDLE_STRUCTURE_REQ_7

Middle Structure Mass Contribution

The Middle Structure's mass shall be at most [16]kg. -

2024_I_ST_MIDDLE_STRUCTURE_REQ_8

Middle Structure Accessiblity

The Middle Structure shall be mounted so as to be within arm's reach of any operator. -

2024_I_ST_MIDDLE_STRUCTURE_REQ_9

Middle Structure Axial Mass Distribution

The Middle Structure's center of mass shall be no further that [10]mm from the LV's central axis.

-

2024_I_ST_GIMBAL_REQ_1

Declaration of Purpose

The Gimbal shall redirect the thrust of the engine based on commands relayed by the electronics. -

2024_I_ST_GIMBAL_REQ_2

Gimbal - Middle Structure Interface

The Gimbal shall be mounted into the middle structure. -

2024_I_ST_GIMBAL_REQ_3

Gimbal Length Contribution

The Gimbal shall not directly contribute to the LV's total length. -

2024_I_ST_GIMBAL_REQ_4

Gimbal Mass Contribution The Middle Structure's mass shall be at most [5.5]kg. -

2024_I_ST_GIMBAL_REQ_5

Gimbal Mechanically Enforced Limits The Gimbal shall be mechanically prevented from reaching angles beyond [20]°. -

2024_I_ST_GIMBAL_REQ_6

Gimbal Torque

The Gimbal torque shall not exceed [4.5]Nm within the allowed motion range. -

2024_I_ST_GIMBAL_REQ_7

Gimbal Angle Resolution

The Gimbal shall ensure a maximum positioning error of the nozzle [1]% within the mecanically allowed angle range. -

2024_I_ST_GIMBAL_REQ_8

Gimbal Angle Timing Precision

The Gimbal shall be able to travel [10]° in less than [100]ms. -

2024_I_ST_GIMBAL_REQ_9

Gimbal Temperature Rating The Gimbal shall be designed to operate at a maximum temperature of [573] K at the attachment point with the engine. -

2024_I_ST_GIMBAL_REQ_10

Gimbal Total Volume

The gimbal mechanism shall fit within a volume of [150x450x450]mm^3.

-

2024_I_ST_LEGS_REQ_1

Declaration of Purpose

The Legs shall ensure the LV remain safe and steady on the ground for the entire duration of operations. -

2024_I_ST_LEGS_REQ_2

Legs Deployed Length Contribution

The Legs' length when deployed shall be at least [600]mm. -

2024_I_ST_LEGS_REQ_3

Legs Mass Contribution

The maximum total mass of the legs — as a whole — shall be [15]kg. -

2024_I_ST_LEGS_REQ_4

Legs Energy Damping

Each Leg shall feature a reversible passive energy damping system. -

2024_I_ST_LEGS_REQ_5

Feather Falling

Each Leg shall resist an impact at [3] m/s for the dry mass with an additional FoS of [1.5]. -

2024_I_ST_LEGS_REQ_6

Legs Ground Stability

The Legs shall be designed to prevent tipping-over at landing with an inclinaison of [20]°. -

2024_I_ST_LEGS_REQ_7

Legs Engine Clearance

The Legs shall ensure a minimum engine clearance with respect to the ground of [40]cm. -

2024_I_ST_LEGS_REQ_8

Legs Terrain Adaptability

The maximum total mass of the legs — as a whole — shall be [15'000]g. -

2024_I_ST_LEGS_REQ_9

Legs Thermic Resistance The foot of each leg shall resist engine hot gases reflection for at least [2]s.

¶ Launch Vehicle Overview

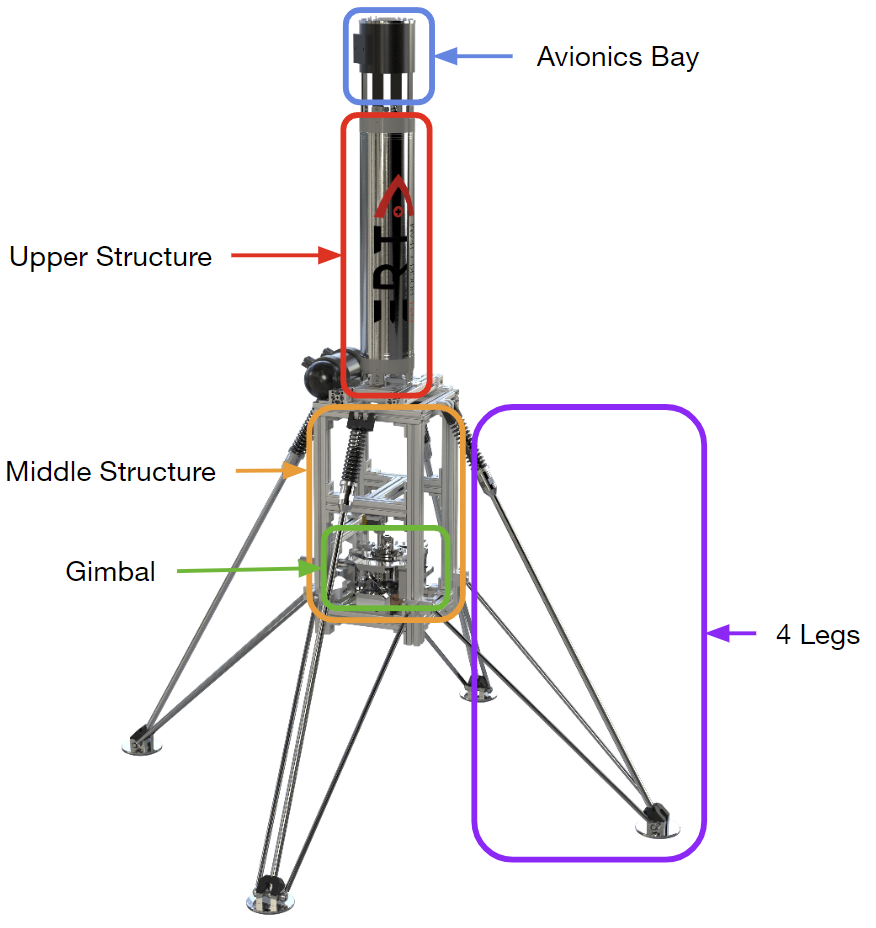

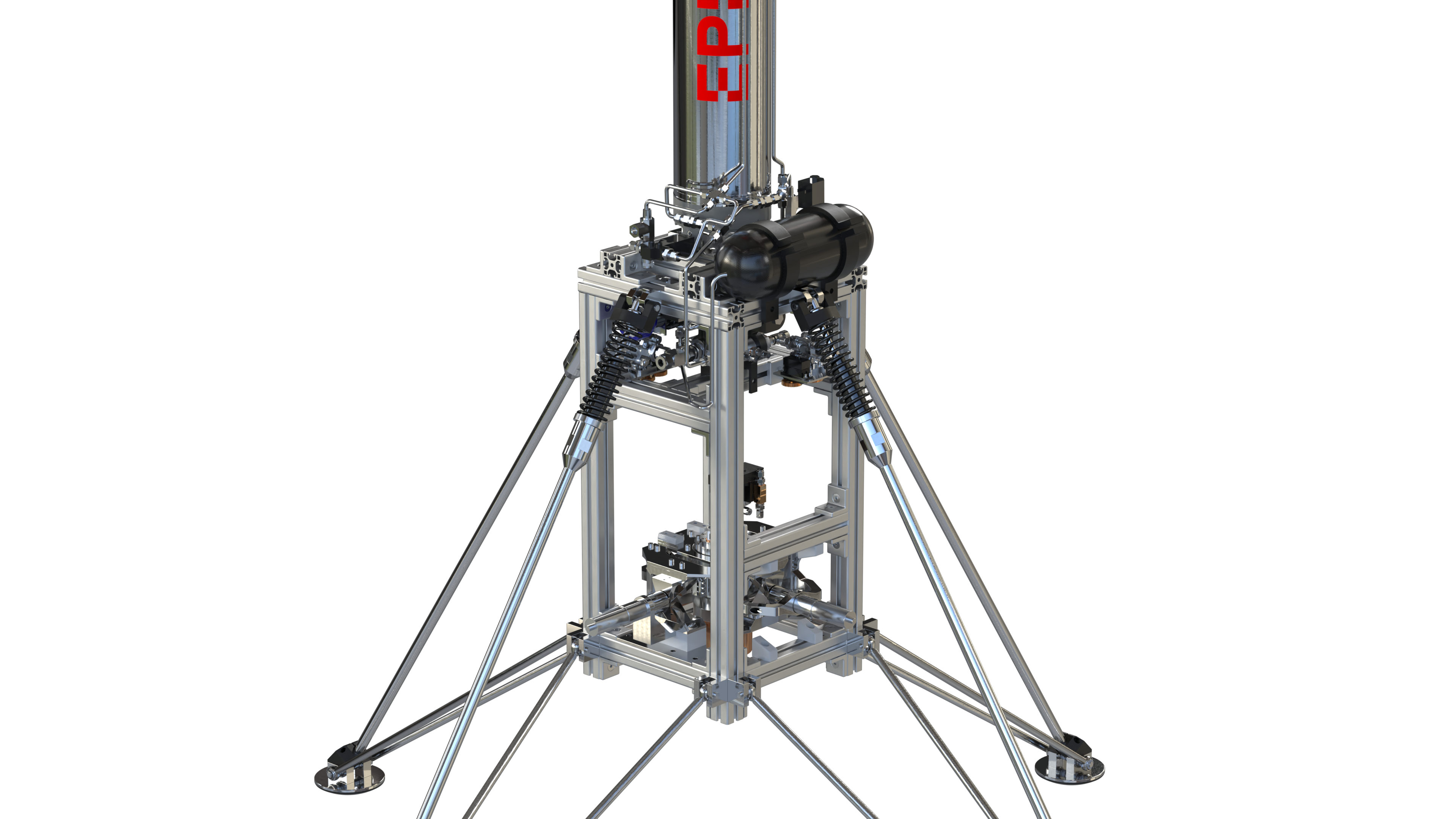

The main function of the structure of the hopper is to link all the parts and subsystems (AV and PR) of the launch vehicle together. The other main function is to assure the protection of the subsystems against the elements and loads. The hopper is seperated into 4 main sub-assemblies:

1. The upper structure: consists of Nordend's backup coaxial tank and of the Avionics bay (where the main sensors stay)

2. The middle structure: composed of an assembly of aluminium profiles. The middle ST connects to all the other sub-assemblies.

3. The gimbal: has the function of holding and guiding the rocket engine DEMO-A3 to achieve the thrust vector control (TVC) necessary to have a stable flight.

4. The Legs : necessary for absorbing the shock of the landing event composed of a damper and spring system

Here is an overview of the current 2024 launch vehicle that has been manufactured.

¶ Sub-sub-assemblies Tree & Nomenclature

As there are over 900 parts on the main Hopper assembly, this tree won't show all the parts but just the sub assemblies of the sub assemblies. It also shows the nomenclature followed to name our parts.

¶ COTS Parts Table

| Part Name | Number of Parts | Main Characteristics | Link to Data Sheet |

|---|---|---|---|

| I14103_Damper | x4 | Stroke = 75mm, Adjustable damping coefficient 300-~300 000 [Ns/m] | Weforma_WE-M 1,25 |

| I14113_Spring | x4 | De = 45mm , L0 = 205, C = 7.94 N/mm, Ln = 81mm | CA 5.00/205.00 on Ressorts du Léman |

| Maxon actuators | x2 | 1:103 Reductor gives : Max nominal torque of 14 [Nm] and Max speed : 6000 [rpm] | Part_3_Datasheet |

| I11303_Oldham_Coupling | x2 | Admissible lateral movement : 2.5 [mm], Outer diameter : 35[mm], Axle diameter : 8 [mm] | MCZ-35-8X8C Coupling |

¶ SRAD Sub assembly Description

¶ Gimbal

The best way to understand the compliant gimbal is to first read the corresponding paper done for the 2023 IAC conference: Flexure-based gimbal with high support stiffness for rocket thrust vector control

This paper regroups all necessary formulas to easily characterise and dimension a flexure based gimbal from the stiffness to the compression or traction force put on a pivot.

A more detailed wiki file on the gimbal can be found in the Gimbal DDF.

¶ Legs

A more detailed wiki file on the legs can be found in the Legs DDF.

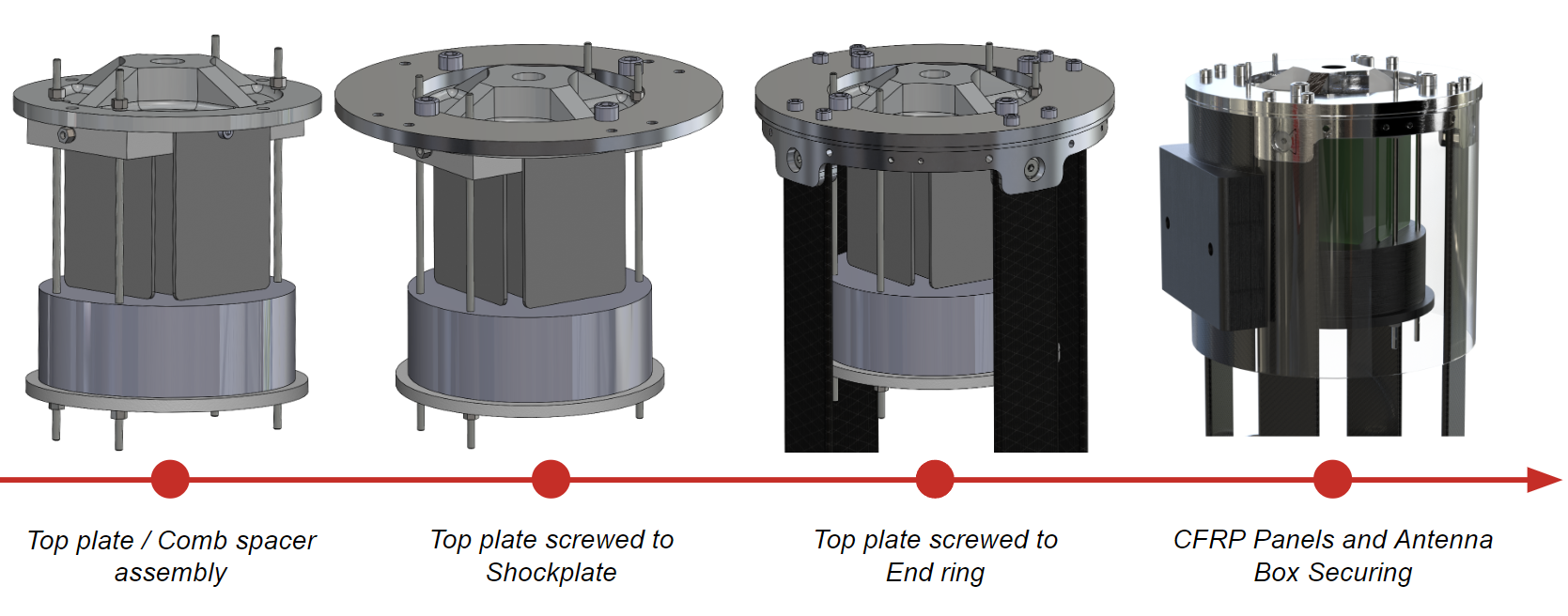

¶ AV Bay

The avionics bay has the purpose to hold the avionics boards.

A more detailed wiki file on the AV bay can be found in the Upper structure DDF.

¶ Upper Structure

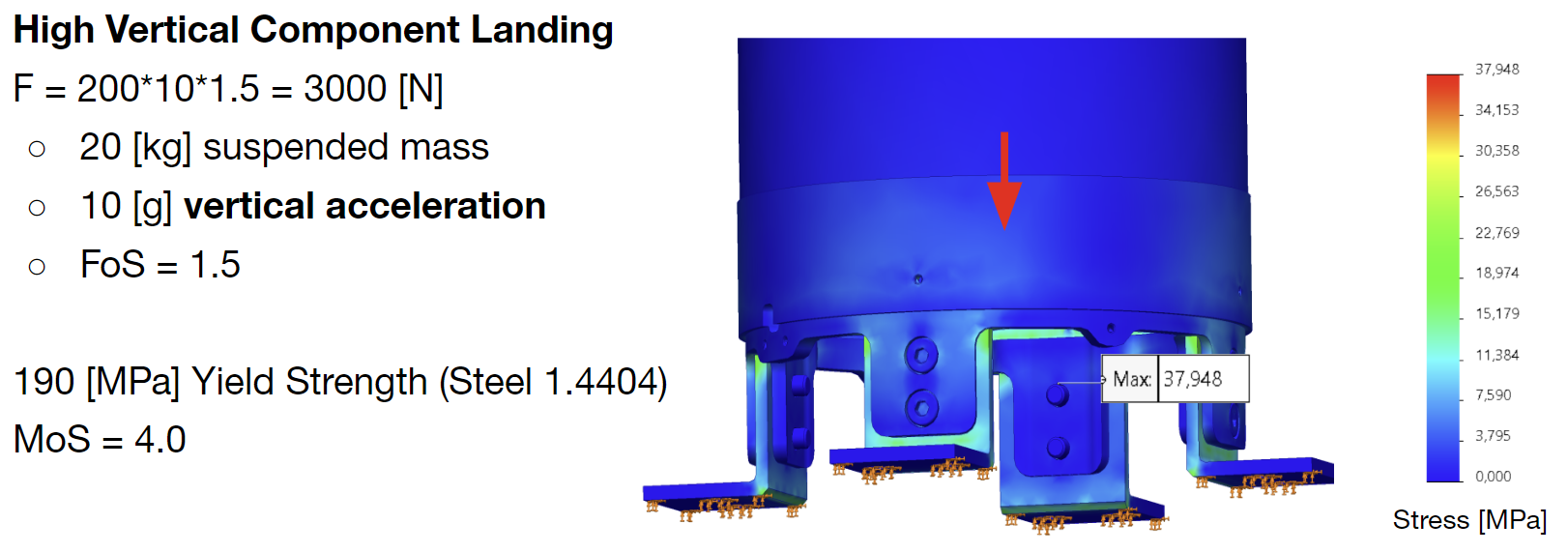

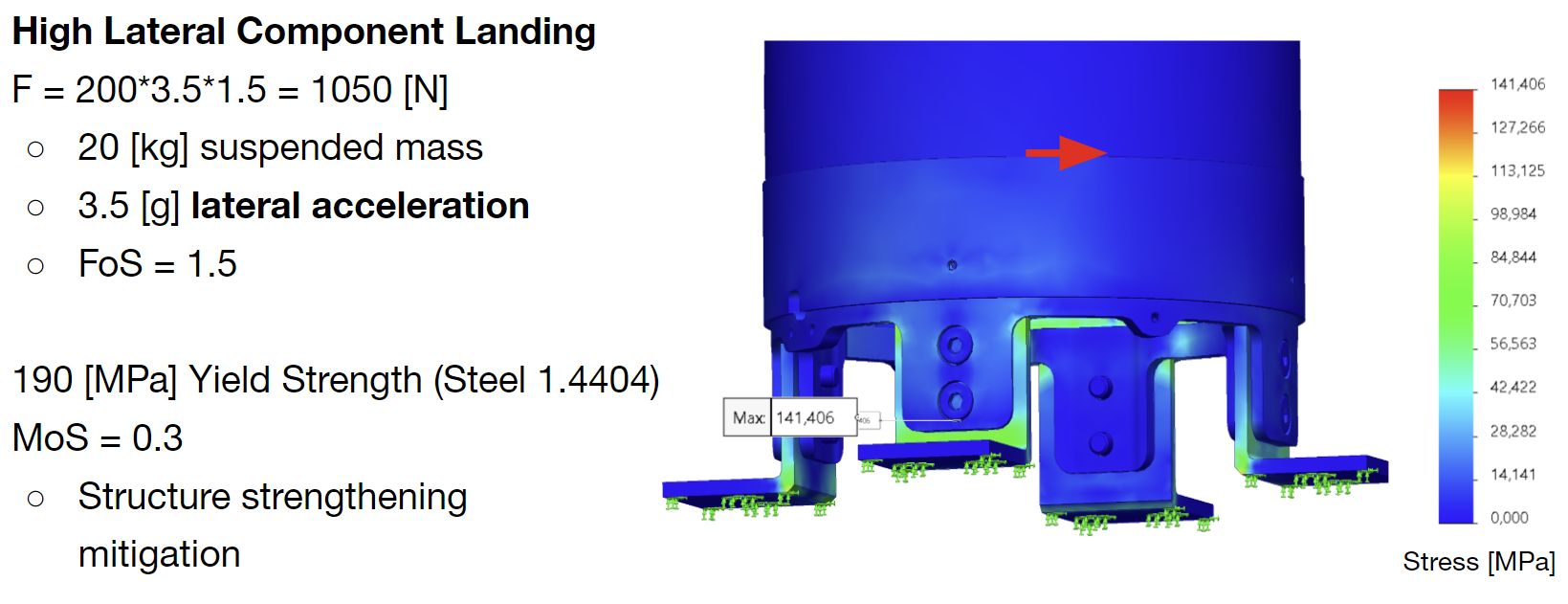

Nordend's tank is fixed to the middle structure using 4 steel brackets. Here are the simulations related to the two axial and radial acceleration loads. The axial simulation has a relatively high margin of safety but the radial load has a quite small margin of safety. This problem could be mitigated by a few solutions; the material could be replaced by a stronger steel with higher yield strength, or the tank could receive bracing with either a structure around it or cables going down to anchor points on the middle structure.

A more detailed wiki file on the Upper Structure can be found in the Upper structure DDF.

¶ Middle Structure

A more detailed wiki file on the Middle Structure can be found in the Middle structure DDF.

¶ Interfaces

The structure part of the hopper has two main interfaces with AV and PR:

The Structure has to hold the main Avionics boards which are in the AV Bay. Then cables run down to a box filled with LiPo batteries and actuator boards (for the gimbal and propulsion). Here is the LLIM with AV:

There are multiple interfaces with the Hyperion Class A rocket engine and plumbing:

- 2024_I_ST_AC_PHY_LLIM_01 Gimbal-Engine Interface

- 2024_I_ST_AC_PHY_LLIM_02 Plumbing Mounting

- 2024_I_ST_AC_PHY_LLIM_03 Plumbing-Tank Interface

¶ Technical Budget, Margins and Deviation

Costs budgets document can be found in 2024_I_SE_BUD.

Length and mass budgets document can be found in 2024_I_SE_LVS.

| Type of value | Units | Actual Value | Requirement Value | Deviation |

|---|---|---|---|---|

| AV Bay | kg | 2.400 | ||

| Upper Structure | kg | 9.800 | ||

| Middle Structure | kg | 15.600 | ||

| Legs | kg | 15.560 |

¶ Design Constraints

¶ Constraints for Production

155 mechanical parts that needed to be machined compose this Hopper ! As these parts were machined by students at the SPOT, this created a need for a production planning so not too many ERT students occupied the machining workshop at once. This document can be found in this document: 2024_I_PRODUCTION-TRACKER. It is advised to use such a document to keep track of which parts are left to machine. This is also a good to not upset Ivan, the mechanical coach.

A maximum of complex curves were made in 5mm thick aluminium plates so these could be laser cut on the laser at the SPOT. Even though the laser had problems, this simplified the production for certain parts.

¶ Constraints for Operation

¶ Transportation

The legs of the hopper can be taken off or can take much less space by removing 8 circlips off of the lower struts of the legs. This allows easy transportation of the dissassembled Hopper. A tool is planned to be designed to more easily remove the legs without the Hopper falling to the ground. This tool should have wheels to easily move the Hopper around.

¶ First flight

When the Hopper will first fly, it is planned to do so attached to a crane. This forced the addition of an eyebolt to the top of the hopper. Calculations were also done to make sure the parts connecting the eybolt to the structure would also hold the stresses.