¶ Introduction

This page is the Design Justification File (DJF) for the Separation Mechanism responsible of the first event : Rocket Separation.

¶ Definitions and Abbreviations

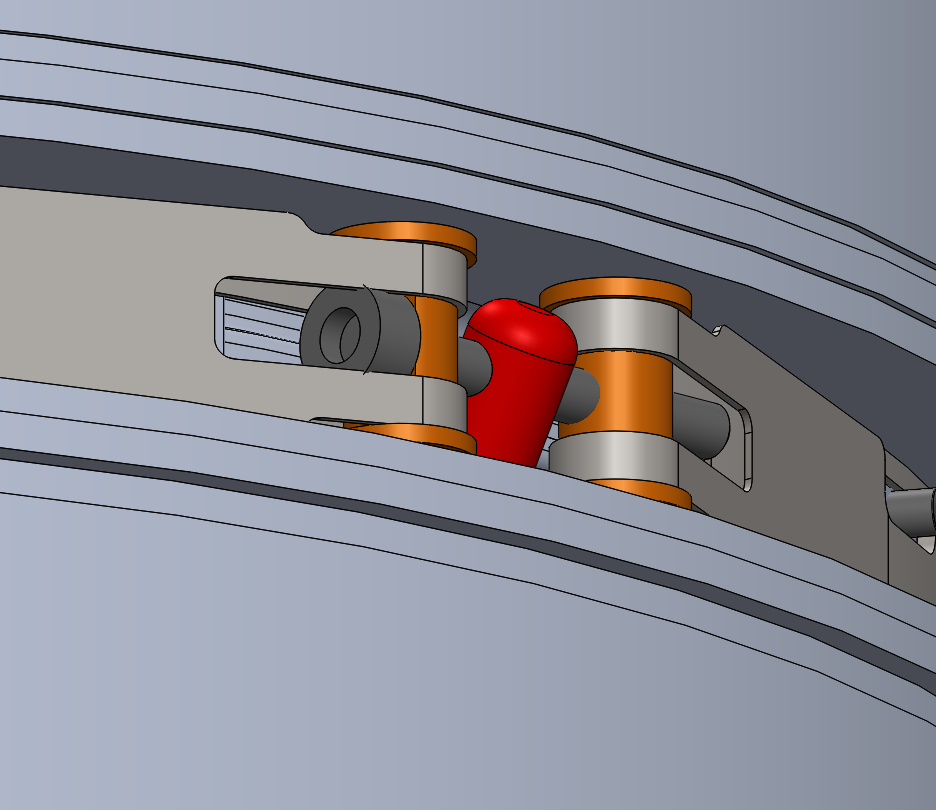

Clamp Band: It's a spring steel band with metallic clamps attached to it. It is tighten around the two rigs of the separation mechanism to to keep together the 2 LV modules before first event and it is released at first event to allow LV separation and drog parashute deploiment

Lower and Upper rings: 2 circular elements attached to the LV designed to be fasten togheder via the clamp band

- DJF : Design Justification File

- SepMec : Separation Mechanism

- CB : Clamp Band

- LV : Launch Vehicle

- ERT : Epfl Rocket Team

- REB : Recovery Bay

- PLB : Payload Bay

- AV : Avionic

¶ Relevant Knowledge Needed

In order to gain a better understanding on what we are looking for and which parameters influences our design's performance, it is important to have an understanding of these core concepts.

- 1st event

- Mechanical SepMec

The easiest way to recover a rocket, without damaging it, is to use parachutes. 1st event is the first occurring in the recovery sequence. It is triggered by LV AV right after apogee detection. ERT LV first event usually correspond to a separation of the LV in 2 parts in correspondence to the SepMec, situated between REB and another LV module (PLB in the case of Firehorm). This separation allow the release of a drogue (or reefed) parachute enabling the begin recovery sequence. The 1st event have to be triggered right after apogee detection and have be fast enough to allow parachute deployment before the LV gain a too high descent speed. This would eventually result in too high deceleration for the LV resulting in too high structural load on the LV structure.

The approach used until now by the ERT is to have a mechanical SepMec. The system is based on the three main component previously described: CB, Upper and Lower Ring. The CB is tighten via a screw in order to couple together the 2 rings respecting the structural LV load requirements. After apogee detection the CB is opened freeing the 2 rings hence the 2 LV modules. This mechanism design have already proven his relatability on previous RET LV and was selected for Firehorn project from the beginning design phase.

¶ Design Options

Being the mechanism similar to the one previously used a design scale up is done in order to adapt the mechanism to the new requirements and load cases. The design is basically a scale-up, reiteration and adaptation of Nordend Separation mechanism with some minor changes. De design phase of CB and Rings follow the same iterative process followed for Nordend SepMec design and detailed in 2023_ST_TN_E02.

A key aspect that is reconsidered for Firehorn is the CB opening system. Even if the previously used method (Dyneema and Nichrome) is still considered, a new option is proposed (Pyro Cutter).

This technique consist in closing the clamp band o one side using a Dyneema cable. It's a cable that can sustain high mechanical tension without compromising the CB integrity when tightened. A Nichrome wire, electrically connected to the board responsible for 1st event detection, is enrolled around the Dyneema wire. After apogee, a high current is used to heat-up the Nichrome wire by joule effect. This is used to melt the Dyneema cable braking up and opening the CB.

System proven on previous ERT LV

No high energy event (Pyro) in the process

Room for redundancies (2 Nichrome wires)

Operation to put in place the system can be tricky, complex and long

Opening time is not easy to be precisely determined and can be longer than the one required

The Dyneema cable introduce a small uncertainties on the CB length and tightening being an elastic cable loop made by splicing.

The risk of cable braking prematurely during flight or assembly procedure is non null.

This solution consist in using a commercial Pyro Cutter to open the BC. The idea is to use this sistem to cut in 2 the tightening screw of the CB.

- Link to the site of a Pyro bolt cutter supplier

{.links-list}

Simple to implement. Commercial Pyro Cutter.

Simpler SepMec integration procedure. Only tightening screw to be placed.

Fast actuation.

Room for redundancies (2 Fastening screw to be cut in different CB points).

Small quantity of Pyro in the system (even if not considered in NON-ENERGETIC category by euroc)

¶ Detailed Design

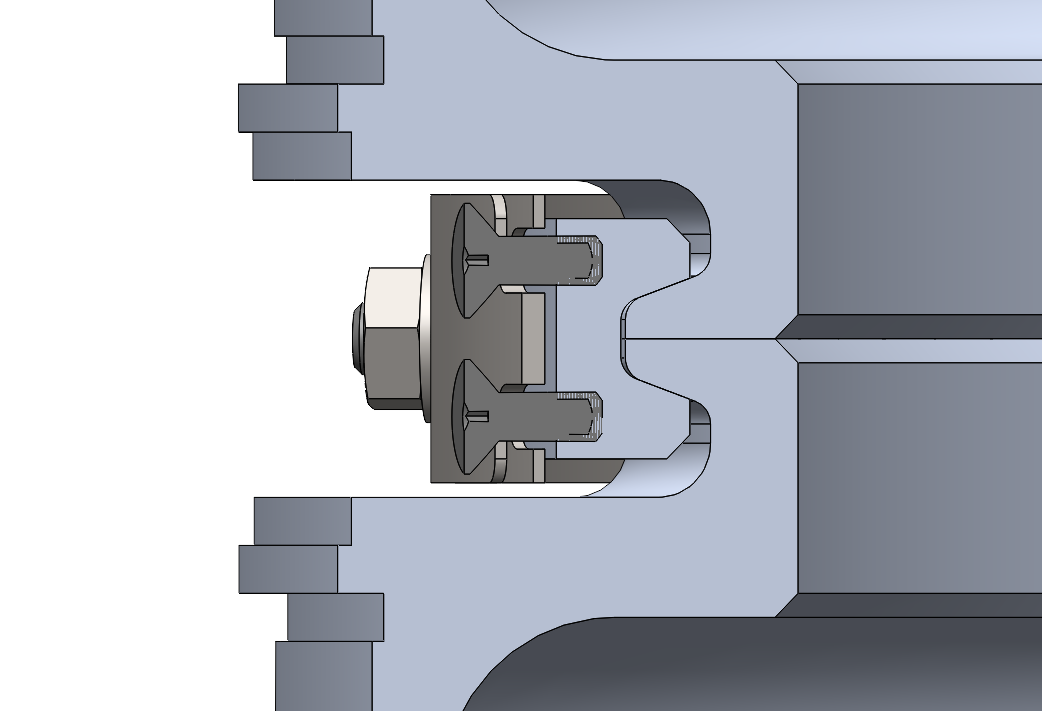

A first iteration of the Pyro Cutter design is shown in this section. This concept will be tested before being finally selected and the Dyneema and Nichrome system will be still kept as a backup option.

Using a pyro cutter would in principle jus trequire to add a hole (min 5mm in diameter) to allow to porition the cylindrical cutter shell and allign it with the tightening screw passing trought it. Only 2 electrical wires going to AV tough the space between RE tube nd the external carbon fiber tube would be needed to be integrated.

It is worth to mention that there is not a lot of space to allocate a pyro cutter so the minimal cutter size needed to cut an M2.5/3 bolt need to be checked with the producer.