¶ title: 2023_ST_TN_B01_Nosecone

description: Link: https://rocket-team.epfl.ch/en/rocket_ss/structure/Nordend/2023_ST_TN_B01

published: true

date: 2025-05-21T19:10:46.420Z

tags:

editor: markdown

dateCreated: 2023-07-13T14:49:58.500Z

¶ title: 2023_ST_TN_B01_Nosecone

description: Link: https://rocket-team.epfl.ch/en/rocket_ss/structure/Nordend/2023_ST_TN_B01

published: true

date: 2024-12-30T21:17:45.590Z

tags:

editor: markdown

dateCreated: 2023-07-13T14:49:58.500Z

¶ title: 2023_ST_TN_B01_Nosecone

description: Link: https://rocket-team.epfl.ch/en/rocket_ss/structure/Nordend/2023_ST_TN_B01

published: true

date: 2023-12-01T02:41:27.473Z

tags:

editor: markdown

dateCreated: 2023-07-13T14:49:58.500Z

¶ Nosecone Technical Note

¶ 1. Introduction

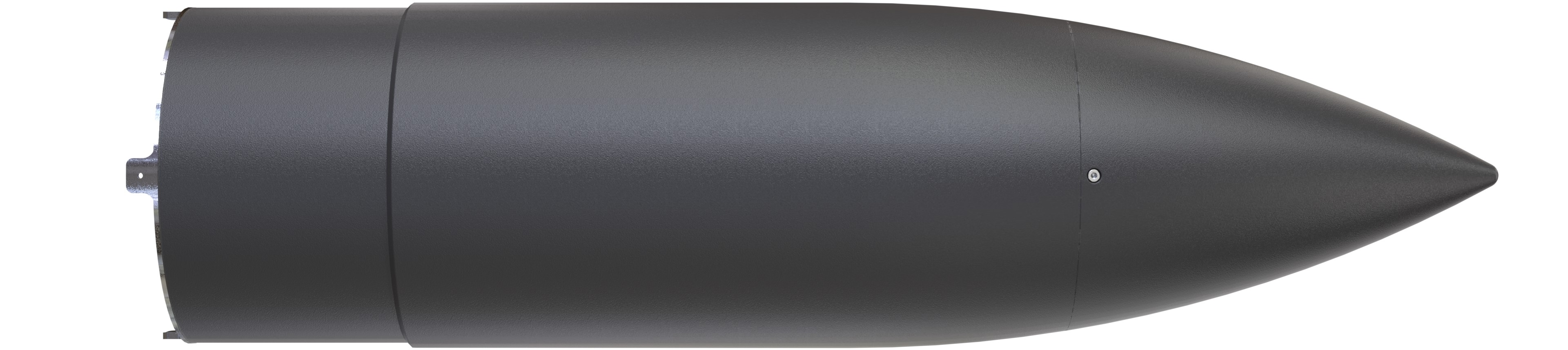

The nosecone of the rocket is the part containing the payload. It also pierces through air, so it has to be aerodynamic. The tangent ogive shape has been chosen for Nordend's nosecone according to FD simulations. It is made of carbon fiber - infused Nylon 6.

In this document we only focus on the design side of the assembly, full production procedure of the nosecone assembly can be found here

¶ 2. Reference Documents

| Ref | Description |

|---|---|

| [RD01] | Nose cone design - Wikipedia |

¶ 3. Definitions and Abbreviations

| LV | Launch Vehicle |

| BL2 | Bella lui 2 |

| WH | Wildhorn |

| RE | Recovery |

| ERT | EPFL Rocket Team |

| EPFL | École Polytechnique Fédérale de Lausanne |

| FD | Flight Dynamics |

| PIS | Payload Integration Structure |

¶ 4. Design

¶ 4.1.Requirements

Engineering requirements :

- 6" base diameter

- Long enough to contain the Payload Integration Structure

- Slid into the RE Module using a slide-in.

- Attached to the RE Module using a nosecone coupler

¶ 4.2. Assembly Overview

¶ 4.2.1 System Specifications

| --- | --- |

| Length | 598 [mm] |

| Weight | 1.142 [kg] |

| Material | Nylon CF - Aluminium|

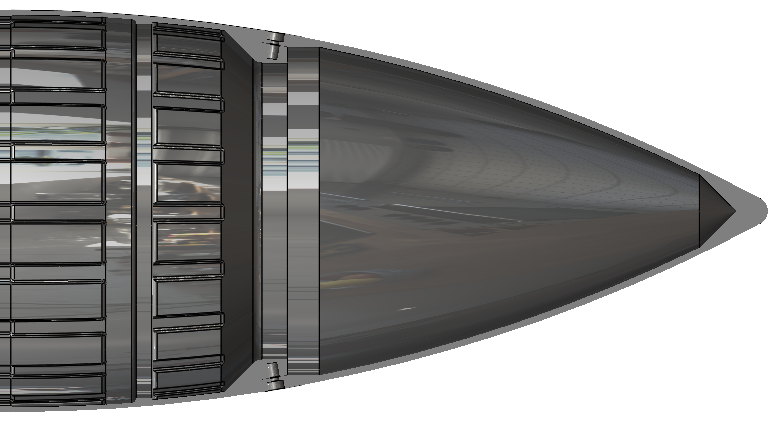

The nosecone is divided in three regions :

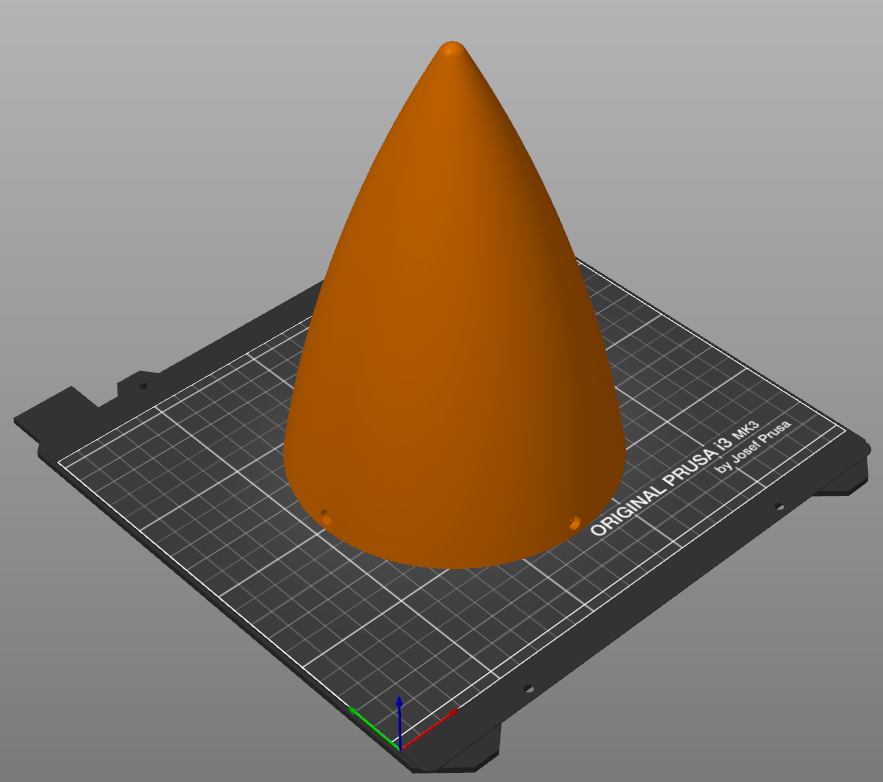

- Cone

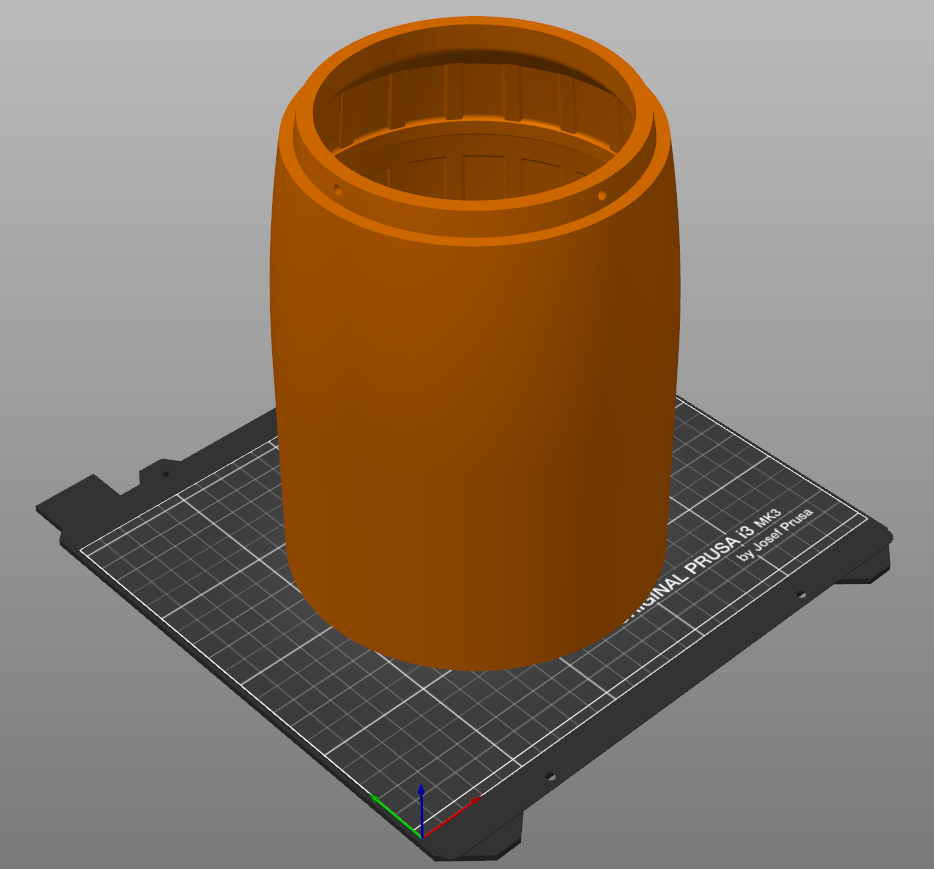

- Cylindrical neck

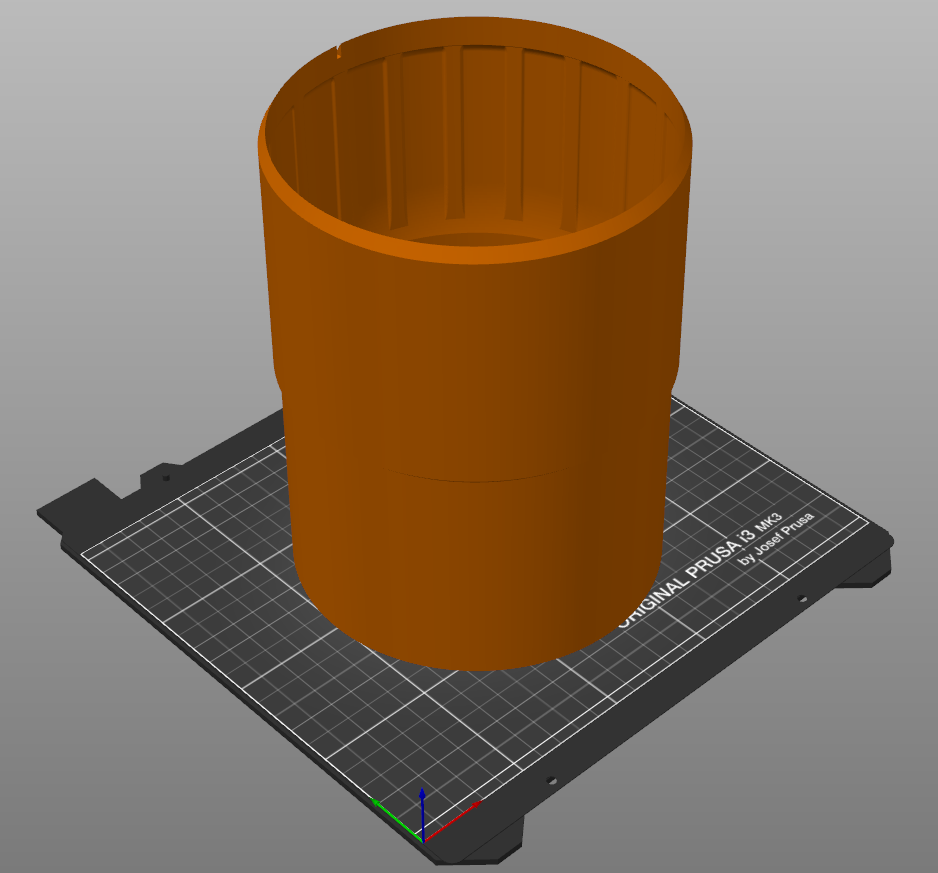

- Slide-in

These are REGIONS, not parts

The nosecone contains the following ST parts / assemblies :

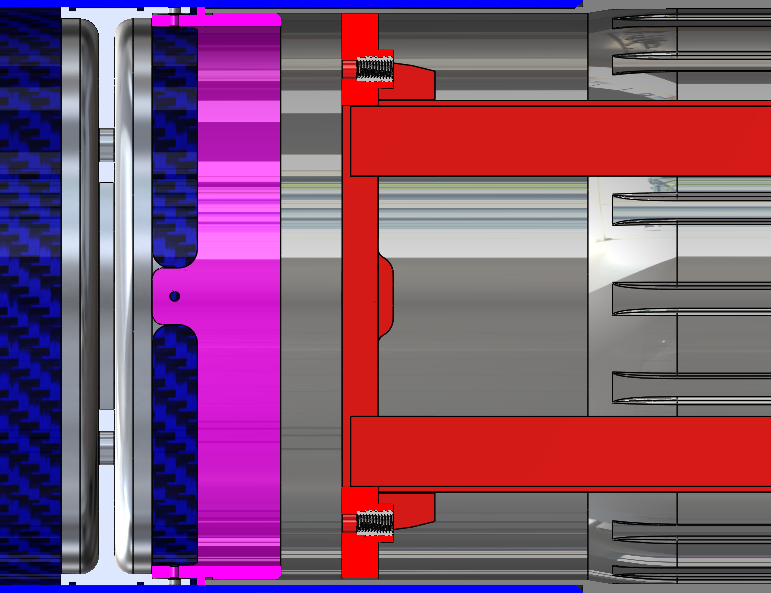

¶ 4.2.2. Annotated Render

This mechanism glued to the inside of the slide in holds the nosecone to the RE module. A full technical note is available here

This mechanism is glued to the inside of the slide in and the cone, it holds the payload. A full technical note is available here

The nosecone is slid into the RE tube (in blue), the slide in has a lower diameter than the RE tube to facilitate insertion.

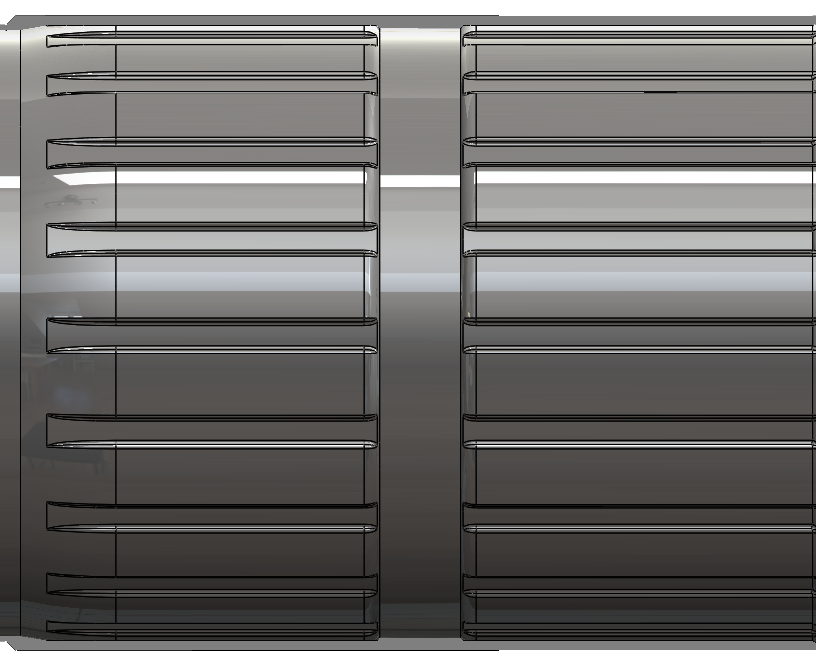

To enhance rigidity the following geometries were added :

- Power ribs along the rocket axis (enhances axial rigidity)

- Thick ring in the middle of the neck (enhances radial rigidity)

Most of the PIS is contained inside the neck.

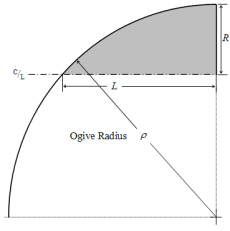

The cone has a tangent ogive shape.

- Ogive radius ρ is given by the formula: ρ = (R² + L²) / 2R (wikipedia)

- Radius y at any point x, as x varies from 0 to L is: y = √(ρ² + (L - x)²) + R - ρ

| Cone dimensions | ||

|---|---|---|

| L [mm] | R [mm] | ρ [mm] |

| 301.6 | 78.5 | 618.63 |

The cone wears the additionnal functionalities :

- Power ribs along the rocket axis (enhances axial rigidity)

- Thick ring in the bottom of the cone (allow a better gluing surface for the PIS top plate)

- Removable tip featuring M4 attachements

¶ 5. FDM Printing

Initially, the cone was intended to be made of CFRP with a simpler shell geometry, and without the removable tip. To do so, a mold was designed to produce the part in one piece. However, some curing problems were encountered making the part unusable. Therefore, the manufacturing method was switched to 3D printing. Nylon-6 infused with carbon fibers was chosen, fulfilling the mechanical requirements.

PA6-CF parts were printed on a prusa Mk3s, due to height constraints the nosecone was printed in 3 parts :

- Tip : removable tip

- Upper : part of the cone and part of the cylindrical neck

- Lower : part of the cylindrical neck and slide-in

Upper and Lower are glued together, using a conical contact geometry.

In this document we only focus on the design side of the assembly, full production procedure of the nosecone assembly can be found here