¶ Introduction

¶ Purpose, Objective and Scope

The present document defines the Payload Bay (PLB) of Firehorn I. Its goal is to precisely describe the PLB and its integration inside the Nosecone Bay, as well as the interface to the Payload (PL) located inside the PLB.

¶ Definitions and Abbreviations

- PLB: Payload Bay

- PL: Payload

- NSB: Nosecone Bay

¶ Applicable and Reference Documents

Before diving deeper into the DDF of the PLB, you might be interested in reading the DJF of the PLB or the LLIM.

¶ Requirements

-

2024_C_SE_ST_NOSECONE_REQ_02 Nosecone declaration of purpose

The nosecone of the LV shall host the PL. -

2024_C_SE_ST_NOSECONE_REQ_04 Nosecone length

The nosecone shall have a length of maximum [1000]mm. -

2024_C_SE_ST_NOSECONE_REQ_05 PL integration

The nosecone shall be able to integrate a PL of the CubeSat standard [RD01] within the 5U format. -

2024_C_SE_ST_NOSECONE_REQ_10 Nosecone load case - Deceleration

The structural elements in the nosecone shall withstand axial tensile loads of [4800]N.

¶ Interfaces

¶ Physical Architecture Overview

¶ Nomenclature

The payload bay

¶ Parts Tree

¶ COTS Parts Table

| Part Name | Number of Parts | Main Characteristics | Link to Data Sheet |

|---|---|---|---|

| Superior Plate | x1 | 3D printed | not applicable |

| Rods | x4 | Alu angular profiles from OBI | OBI Rods |

| Inferior Plate | x1 | 3D printed | not applicable |

| Fixation Plate | x1 | Water cut in Carbon Fiber | not applicable |

| M4x14 screws | x4 | Bought |

¶ SRAD Parts Description

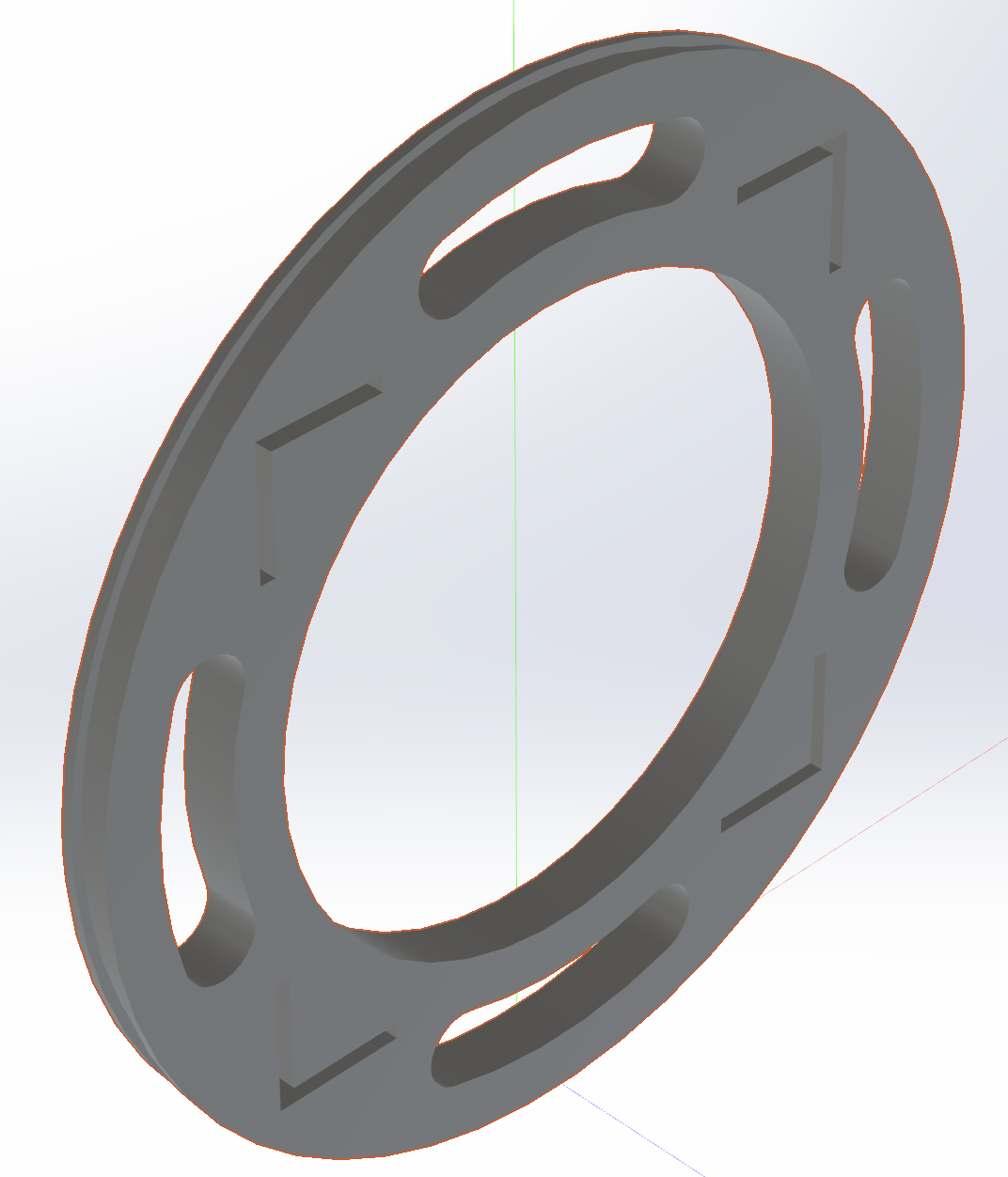

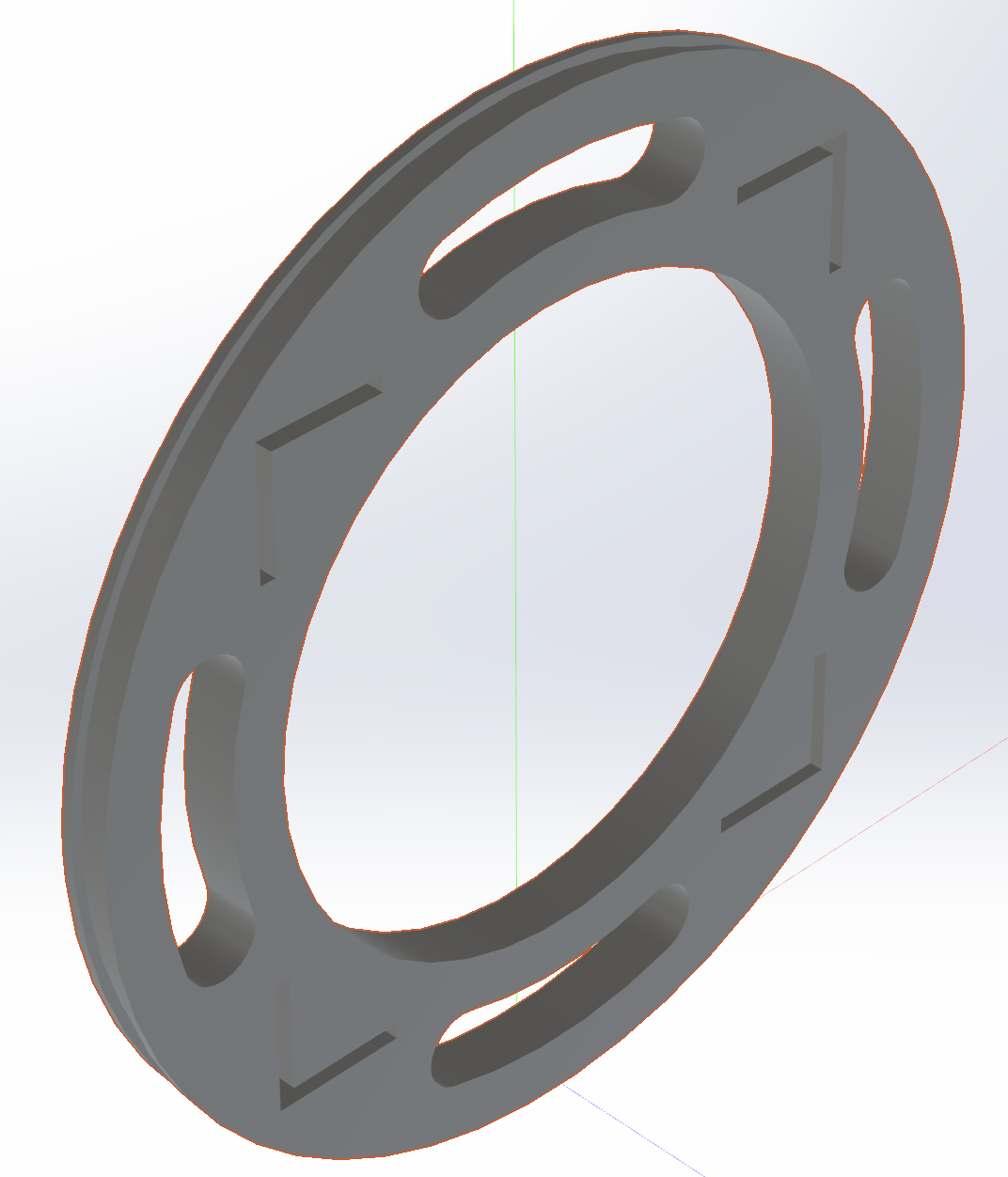

¶ Superior Plate (x1)

¶ Description

| Specification | Value | Unit |

|---|---|---|

| Dimensions | ~159 x 9 | [mm] |

| Mass | 71 | [g] |

| Design load | 2400 | [N] |

| FoS | 2 | |

| MoS | 5.05 | |

| Manufacturing | 3d print | |

| Fastening | Glue | |

| Cost | 3.55 | [CHF] |

This part is 3D printed and glued to the Nosecone and the Rods.

¶ Possible improvements

Bigger surface area for the glue

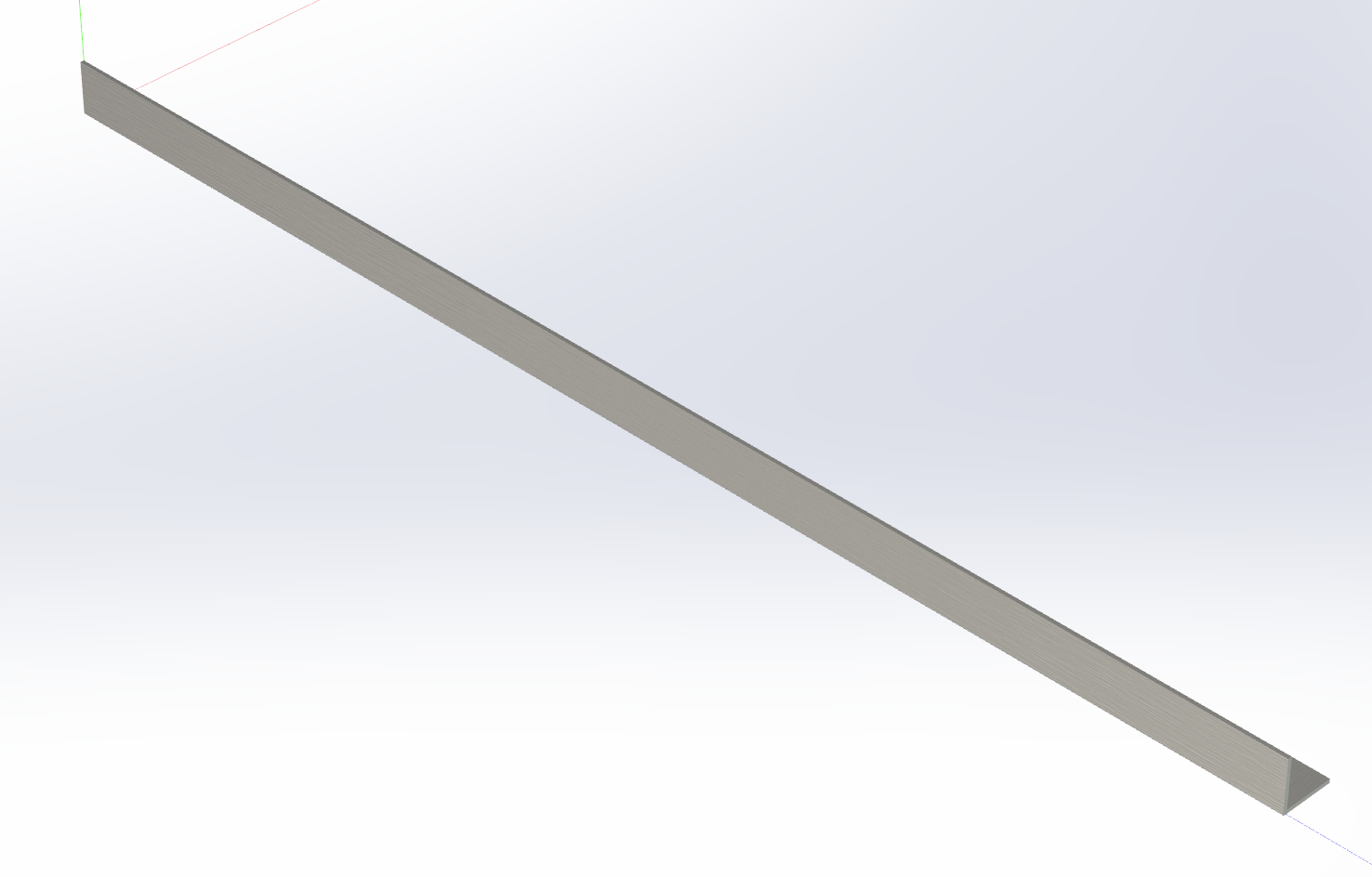

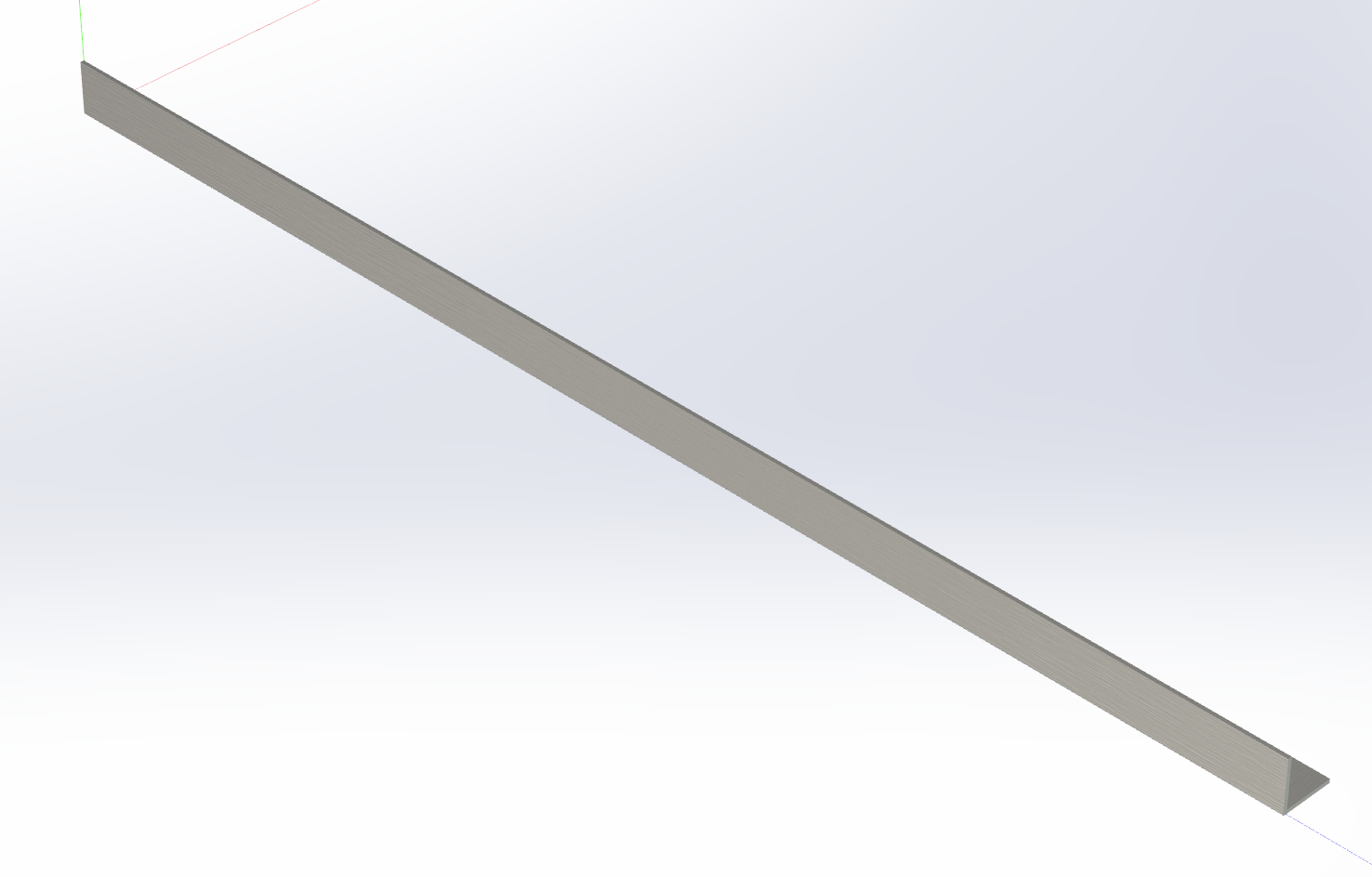

¶ Rods (x4)

¶ Description

| Specification | Value | Unit |

|---|---|---|

| Dimensions | 500 | [mm] |

| Mass | 78.7 (1 rod) | [g] |

| Design load | 600 (2400/4) | [N] |

| FoS | 2 | |

| MoS | 8.67 | |

| Manufacturing | Saw + milling machine | |

| Fastening | Glue | |

| Cost | 12.90 | [CHF] |

The Rods are aluminium angular profiles from OBI (20x20x1,5mm). They guide the PL.

¶ Possible improvements

(Feel free to make suggestions)

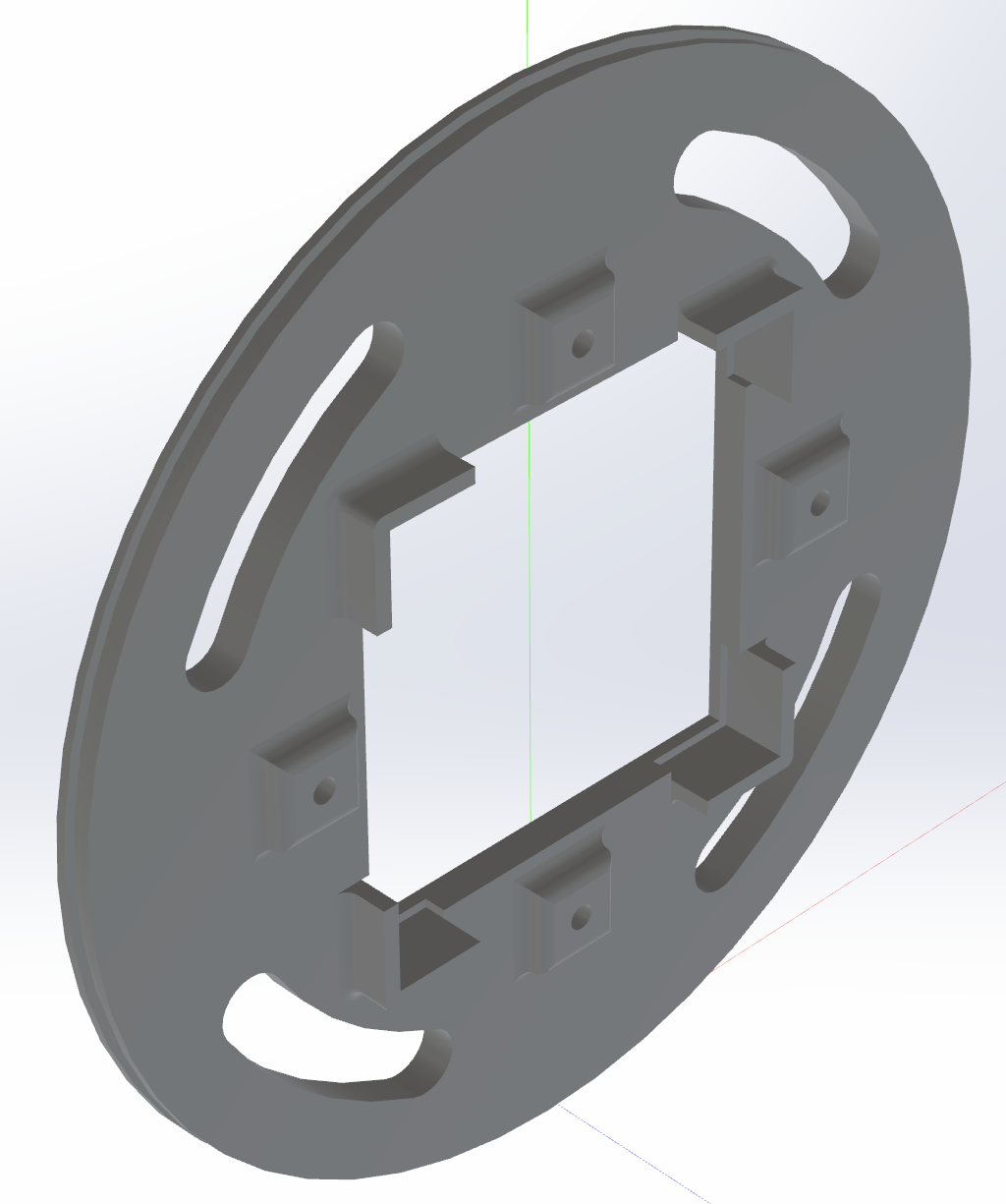

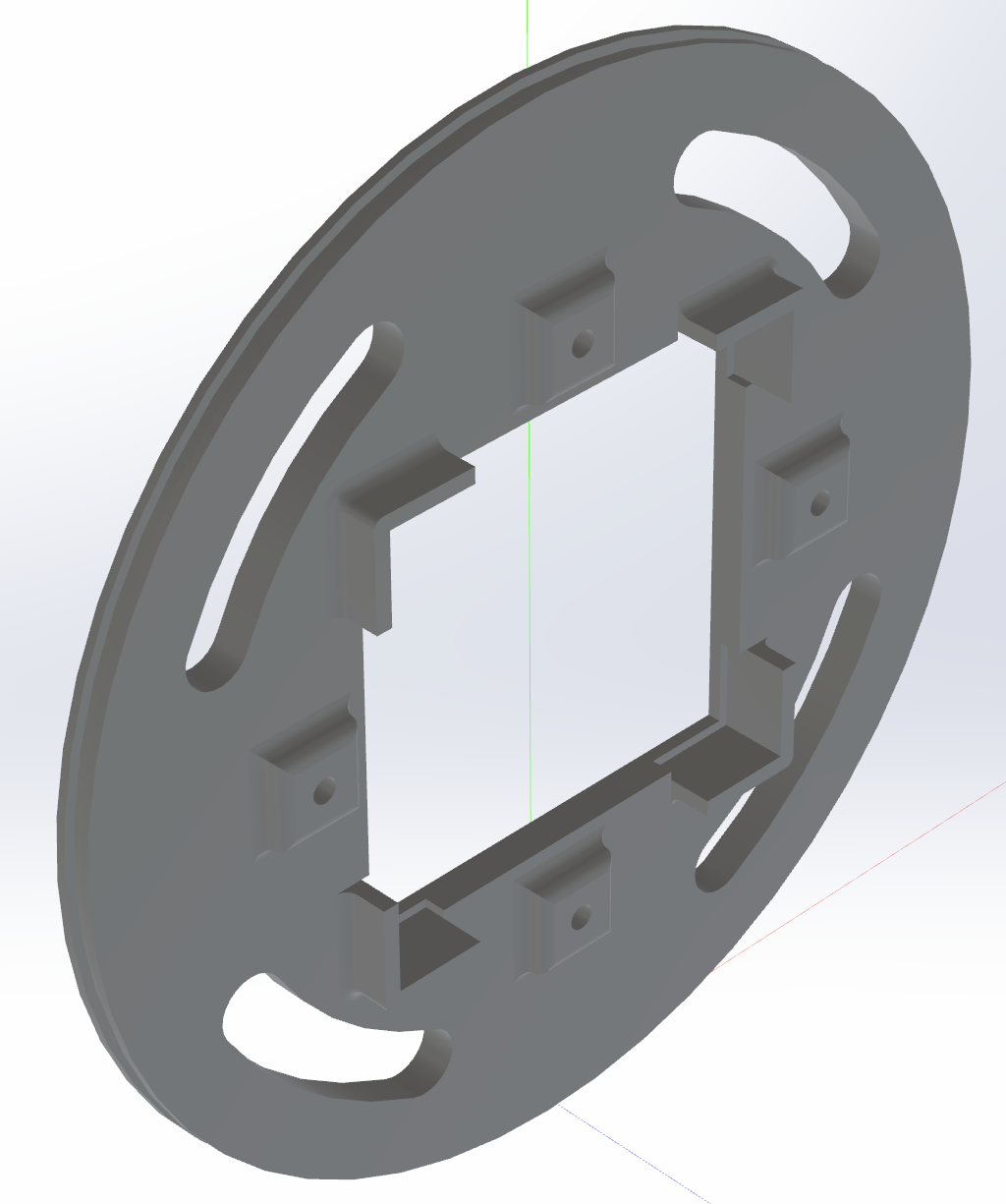

¶ Inferior Plate (x1)

¶ Description

| Specification | Value | Unit |

|---|---|---|

| Dimensions | 235 x 18 | [mm] |

| Mass | 182 | [g] |

| Design load | 2400 | [N] |

| FoS | 2 | |

| MoS | 10.83 | |

| Manufacturing | 3d printing | |

| Fastening | Glue | |

| Cost | 9.1 | [CHF] |

This part is 3D printed and glued to the Nosecone and the Rods.

¶ Possible improvements

Same as for the superior one : more surface area for the glue

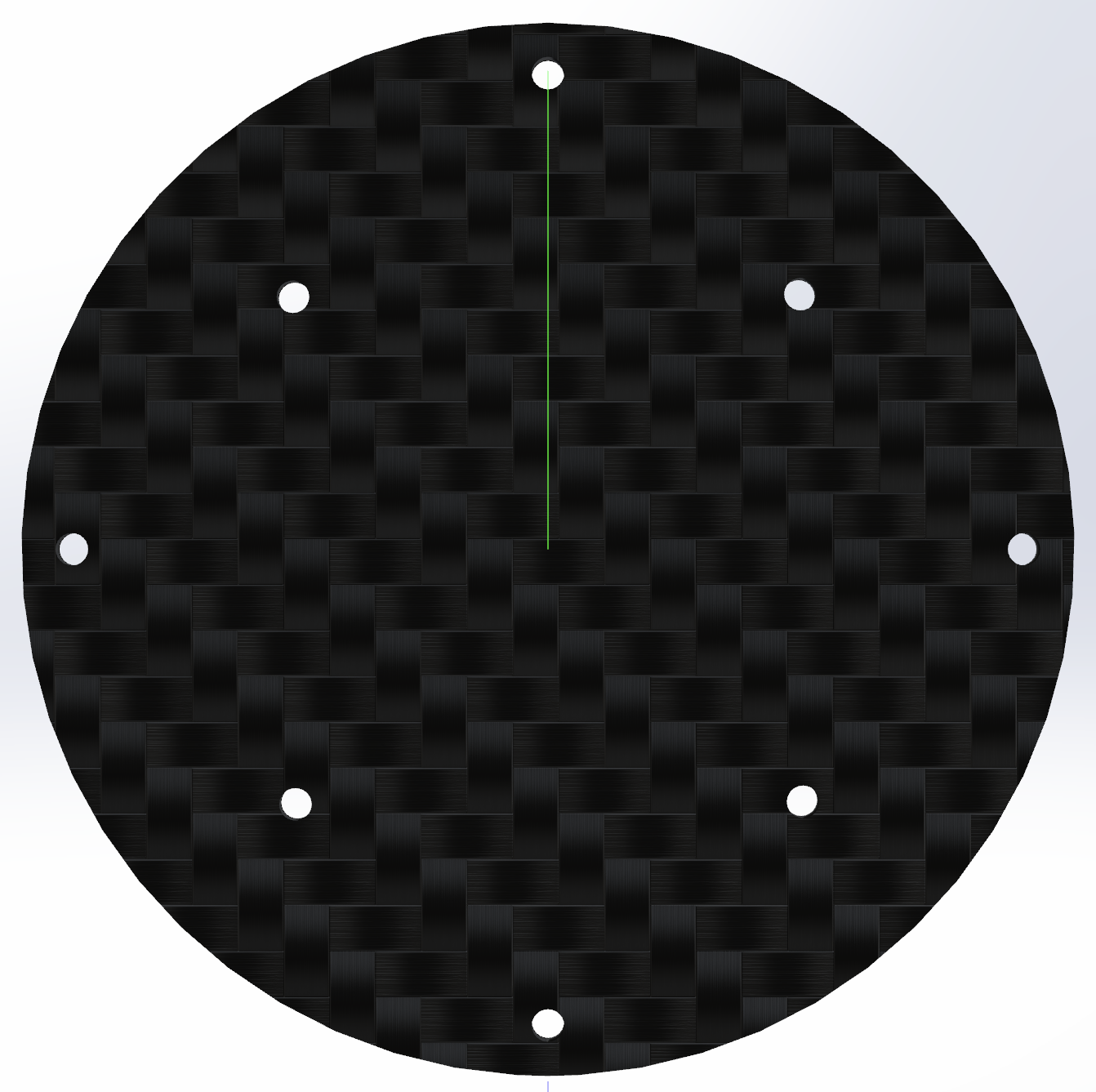

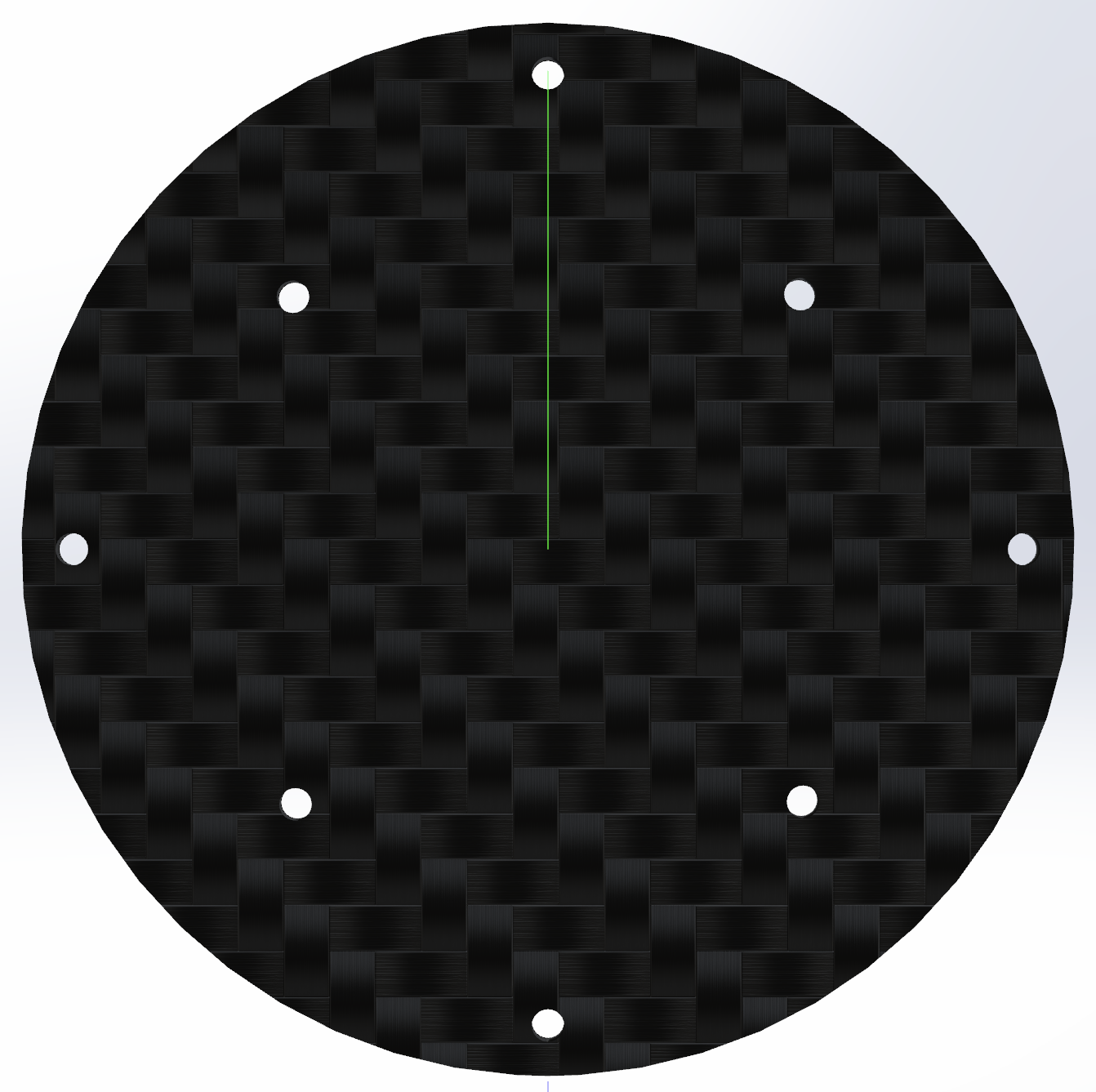

¶ Fixation Plate (x1)

¶ Description

| Specification | Value | Unit |

|---|---|---|

| Dimensions | 146 x 5 | [mm] |

| Mass | 57.8 | [g] |

| Design load | 2400 | [N] |

| FoS | 2 | |

| MoS | 8.9 | |

| Manufacturing | Water cut | |

| Fastening | M4 screws | |

| Cost | 30 | [CHF] |

This part is cut in Carbon Fiber and screwed to the bottom of the Inferior Plate and the PL.The Fixation Plate is screwed to its bottom using M4 3D inserts.

Link to plate before being cut:

https://shop.swiss-composite.ch/pi.php/Halbfabrikate/Plattenmaterial/CFK-Prepreg-Platten/Carbon-Prepreg-Platten-30mm.html

¶ Possible improvements

(Feel free to make suggestions)

¶ Functional Description

The only function of the PLB is to properly integrate the PL inside the Nosecone Bay for an easy removal during EuRoc to weigh the PL.

¶ Function Tree

¶ Function Table

| Function | Part(s) involved | Interfaces | Performance Requirements |

|---|---|---|---|

| Proper integration of the PL inside the NSB | Superior_Plate, Inferior_Plate, Rods, Fixation_Plate | Nosecone | Once in place, the PL isn't moving relatively to the PLB |

| Easy removal of the PL | Fixation_Plate | Inferior_Plate | One person can easily extract the PL attached to the Fixation_Plate |

¶ Technical Budget, Margins and Deviation

| Type of Value | Units | Requirement Value | Actual Value | Deviation |

|---|---|---|---|

| Dimensions |[mm]| 5u format| 5u format | 0%|

|Force | [N]| Axial tensile loads of 4800N | (to be verified)| |

|Weight|[g] | Total mass of e | | |

¶ Design constraints

¶ Constraints for Production

The fact that the Payload was slided in with the payload bay already glued inside the nosecone made it difficult to find a design using screws to connect the rods to the plates. Thus, glue was chosen, even though it may not be as strong.

¶ Constraints for Operation

Make sure to leave the fake payload for as long as possible in order to avoid the twisting of the rods.