¶ Introduction

The purpose of this document is to define and describe the final design of the Pyrocutter system, ensuring that it complies with the technical requirements and operational objectives of the Rocket Team project.

The objective is to provide a comprehensive technical reference that explains the system’s design choices, key specifications, and experimental results. This document is intended for project supervisors, team members, and future developers who need to understand the design rationale, assembly details, and performance characteristics of the pyrocutter.

The scope of this document focuses on the pyrocutter assembly, including the mechanical body, the black powder reservoir, the tungsten carbide projectile, and the projectile retention system. Each component is described both at the assembly level (how the parts integrate into a complete functional system) and at the part level (individual design and manufacturing details).

¶ Definitions and Abbreviations

- ABV : Abbreviations

- SepMech : Separation Mechanism

¶ Applicable and Reference Documents

¶ Requirements

- 2024_C_SE_ST_REQ_01

The Separation Mechanism shall allow the LV to separate and deploy a drogue parachute or a reefed parachute at apogee.

- 2024_C_SE_ST_REQ_02

The Separation Mechanism shall not interfere in any way with the deployment of the RE systems.

- 2024_C_SE_ST_REQ_03

The Separation Mechanism shall result in a free internal diameter larger than [200]mm.

- 2024_C_SE_ST_REQ_04

The Separation Mechanism shall deploy in less than [3]s.

- 2024_C_SE_ST_REQ_05

The assembly of the Separation Mechanism shall take less than [15]min.

- 2024_C_SE_ST_REQ_06

After it has been used, it shall cost less than [20]CHF to repair the Separation Mechanism.

- 2024_C_SE_ST_REQ_07

The Separation Mechanism shall withstand a bending moment of [3000]Nm around an axis perpendicular to the main LV axis.

- 2024_C_SE_ST_REQ_38

The FH I LV shall resist compression induced by a compression force of [10000]N instead of [15000]N.

¶ Interfaces

The pyrocutter system is integrated into the separation mechanism with two devices arranged symmetrically, each inserted into a dedicated hole on either side of the shockpler.

-

With the Shockpler: The pyrocutter bodies are housed in two machined holes in the shockpler. This positioning ensures accurate alignment of the projectiles with the clamp band screws.

-

With the Clamp Band: Each pyrocutter is oriented to cut through the M3 tightening screw of the clamp band. Once severed, the clamp band releases and allows the upper and lower rings to separate.

-

Electrical Interface (Avionics System): The e-matches inside the pyrocutter are triggered by the avionics system after apogee detection, ensuring precise timing of activation.

-

Symmetry and Redundancy: The use of two pyrocutters,in opposition, balances the system mechanically and adds redundancy, guaranteeing separation even if one unit fails.

-

With Fasteners (Nuts/Screws): The pyrocutters are mechanically secured using nuts and integrated fasteners, preventing unwanted displacement due to vibration or acceleration during flight.

This interface configuration ensures secure positioning, reliable triggering, and rapid clamp band release, even under extreme flight conditions.

¶ Overview

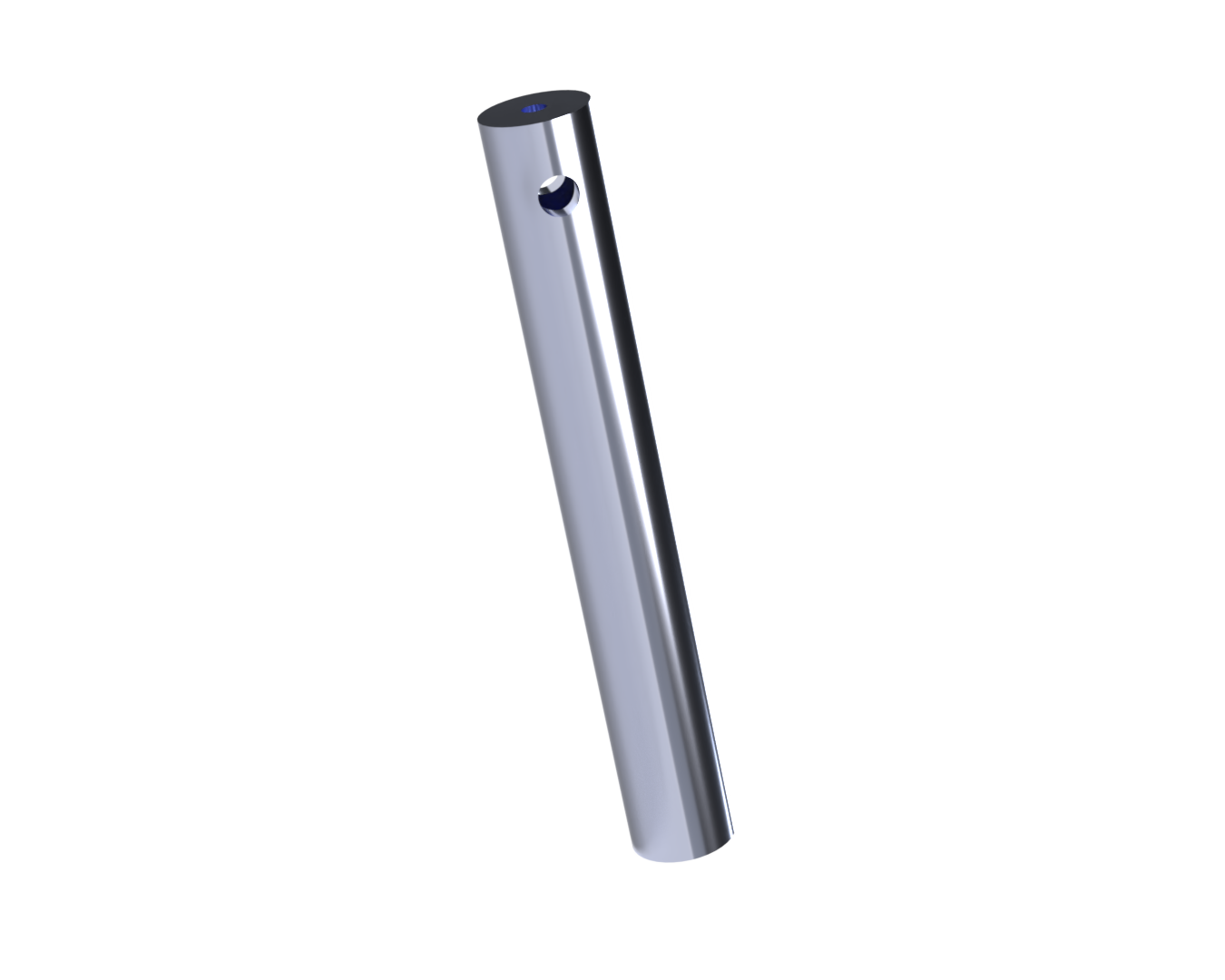

The pyrocutter assembly is a pyrotechnic separation device designed to cut the clamp band screw and enable reliable stage separation. It consists of two identical units, mounted symmetrically on either side of the shockpler.

The assembly is made of three main mechanical components:

-

Body – Steel housing providing structural support and alignment.

-

Reservoir – Internal chamber holding compressed black powder.

-

Projectile – Tungsten carbide tip accelerated by gas expansion to cut through an M3 screw.

The projectile is held in place before activation by an epoxy adhesive layer. An alternative solution could be a pin, ensuring robustness under vibration and inverted mounting conditions.

¶ Parts Description

¶ Body

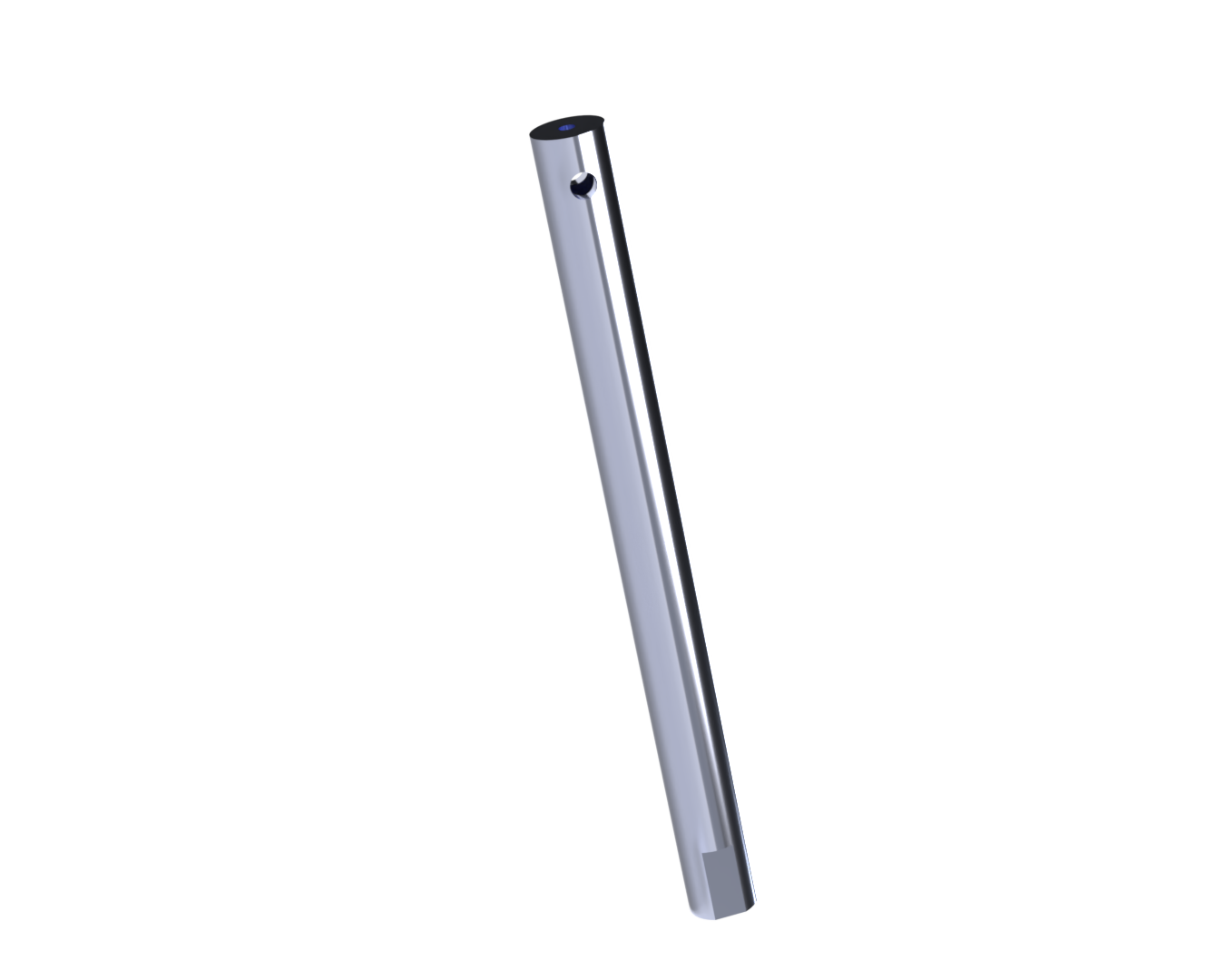

¶ Description

The body is the structural part of the pyrocutter that provides the projectile with enough space to accelerate before striking and severing the M3 screw. The projectile is housed at the extremity of the body, aligned with the screw to ensure efficient cutting.

The body features two side holes to allow the clamp band screw to pass through, as well as an additional rear hole. This rear hole makes the pyrocutter reusable: it enables the removal of the projectile after a test using a punch tool.

¶ Main Specifications

| Specification | Value | Unit |

|---|---|---|

| Dimensions | 11 x 11 x 60 | [mm] |

| Mass | 5 | [g] |

| Factor of Safety | 2 | |

| Material | Steel A36 | - |

| Manufacturing cost | 500 for 10 pieces | [CHF] |

¶ Interfaces

-

With Reservoir: The reservoir is screwed into the base of the body, forming a sealed chamber that contains the black powder and supports the e-match.

-

With Projectile: The projectile is seated at the bottom of the internal chamber of the body. It is initially fixed in place with epoxy until ignition, and guided by the body during its acceleration.

-

With Clamp Band Screw: The body features two lateral holes aligned with the tightening screw of the clamp band. When the pyrocutter is activated, the accelerated projectile passes between these holes and cuts through the screw.

-

With Shockpler: The body is inserted into a dedicated housing in the shockpler and secured with nuts, ensuring correct alignment and mechanical stability during flight.

-

With Rear Hole (Reusability): An additional hole at the top of the body allows the projectile to be pushed out with a punch tool after test firings, making the body reusable.

¶ Technical Drawings

_page-0001.jpg)

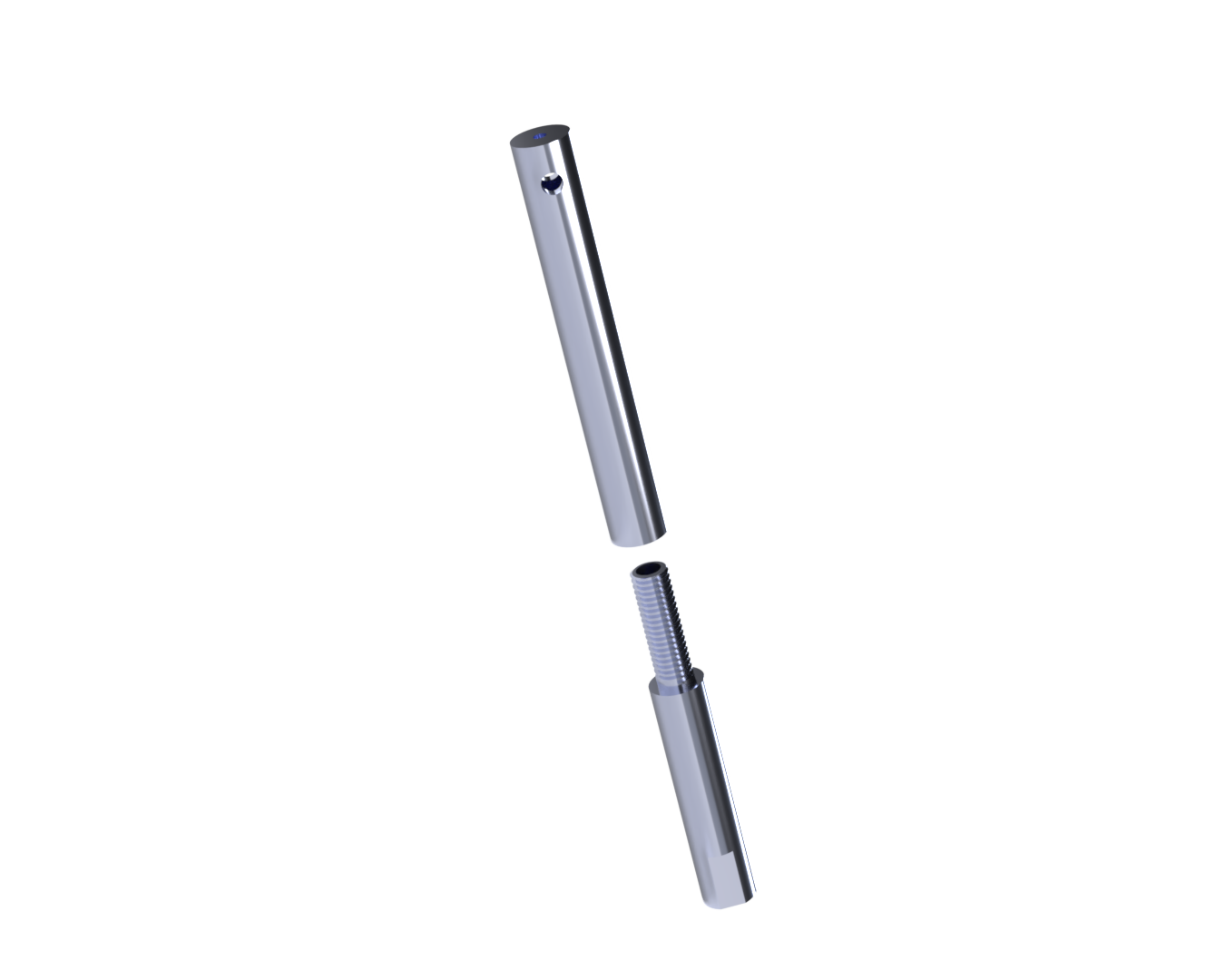

¶ Powder Chamber

¶ Description

The reservoir is the chamber where the black powder is loaded and compressed. It is directly connected to the e-match, which ignites the powder charge upon signal from the avionics system.

The projectile is glued at the bottom of the reservoir using epoxy resin, which maintains it in place before firing. The epoxy burns or releases during ignition, allowing the projectile to be propelled forward without obstruction.

¶ Main Specifications

| Specification | Value | Unit |

|---|---|---|

| Dimensions | 11 x 11 x 60 | [mm] |

| Mass | 5 | [g] |

| Factor of Safety | 2 | |

| Material | Steel A36 | - |

| Manufacturing cost | 500 for 10 pieces | [CHF] |

¶ Interfaces

-

With Body: The reservoir is screwed into the base of the body, creating a sealed chamber that contains the black powder.

-

With Projectile: The projectile is positioned at the bottom of the reservoir and held in place with epoxy until ignition. Once the black powder is ignited, the gases push the projectile into the body’s acceleration chamber.

-

With E-match: The reservoir houses the e-match, which ignites the black powder charge upon receiving an electrical signal from the avionics system.

-

With Shockpler: Through its integration into the body, the reservoir is indirectly supported by the shockpler structure, ensuring stability under flight conditions.

¶ Technical Drawing

_page-0001.jpg)

¶ Retention Methods

Two possible approaches have been considered for securing the projectile in place before firing:

- Epoxy Method

The projectile is bonded to the base of the reservoir using 5-minute epoxy. This method provides sufficient strength to hold the projectile in position during handling and integration, while allowing reliable release when the black powder charge is ignited.

- Pin Retention

An alternative solution consists of placing a plastic retention pin just above the tip of the projectile, across the reservoir. During operation, the pressure generated by the combustion of black powder propels the projectile forward, cutting the pin and freeing the path through the screw to be severed. This method has the advantage of avoiding the use of adhesives and making the retention system reusable.

¶ Possible Improvements

Several optimizations could be introduced to improve the manufacturability, integration, and performance of the pyrocutter system:

-

Shortening of Body and Reservoir: The overall length of the body and reservoir could be reduced to allow direct manufacturing at the school’s SPOT workshop, removing the need for external suppliers. This would lower costs and improve turnaround times for prototyping.

-

Standardized Threading: The current M7 interface between the body and the reservoir is not standard. Switching to an M6 or M8 thread would make the design more compatible with standard tooling and simplify production.

-

Projectile Passage Optimization: The projectile passage hole (currently Ø5 mm) could be slightly enlarged to allow a broader range of projectile geometries and improve cutting reliability.

-

Machining the pyrocutter by our own as at the beginning and in inox steel.

-

Developping the pin retention method.

-

Increased Powder Efficiency: By slightly enlarging the reservoir chamber, it would be possible to load the same or a greater amount of black powder while keeping the pyrocutter shorter. This would reduce mass and length while maintaining cutting effectiveness.

¶ Design Constraints

¶ Constraints for Production

The production of the pyrocutter body and reservoir was limited by the available tooling at the SPOT workshop. Specifically, no drill bits or machining tools were long enough to manufacture the internal cavity of the body and reservoir. In addition, the current design uses an M7 threaded interface between the body and the reservoir, which is non-standard and not supported by the school’s tooling set. As a result, the components had to be ordered externally and manufactured by a supplier, instead of being produced directly in-house.

¶ Constraints for Operation

The system involves the use of black powder, which requires careful handling, storage, and integration to ensure safety. Assembly of the pyrocutter must follow a strict procedure to avoid unintentional ignition, and operators must be trained in handling pyrotechnic components. Furthermore, once assembled, the system cannot be dismounted without discharging, which limits operational flexibility.

¶ Other Constraints

Transportation and storage of the pyrocutter are constrained by safety regulations related to black powder and e-match components. Additionally, while the body has been designed with a rear hole for reusability (to remove the projectile after testing), repeated firings may wear out the internal threading and sealing surfaces, limiting the number of reuses before replacement.

The manufacturing of the projectile requires particular methods due to its geometry and precision requirements. The shaping of the projectile nose is achieved by machining and then refined using sandpaper mounted on a flat belt to obtain the correct taper and surface finish. Final dimensioning and fine adjustments are performed with a Dremel tool, which allows achieving the precise fit required for both the body cavity and the retention method.

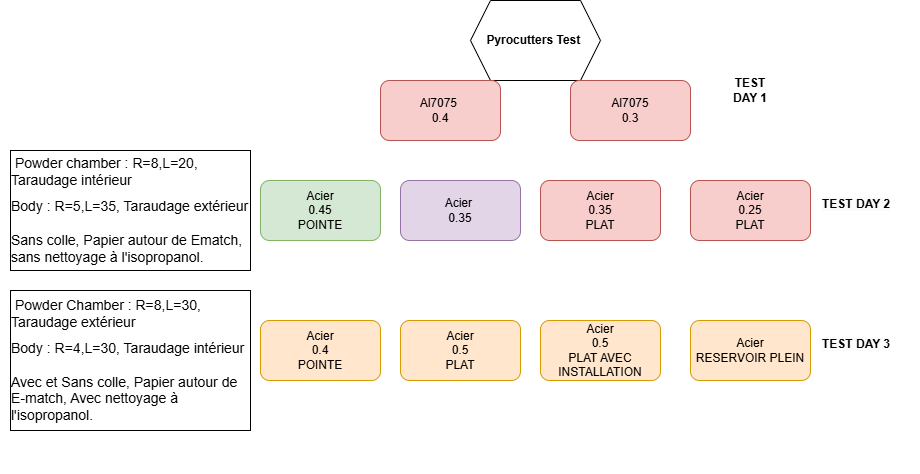

¶ Early Design Studies of the Pyrocutter

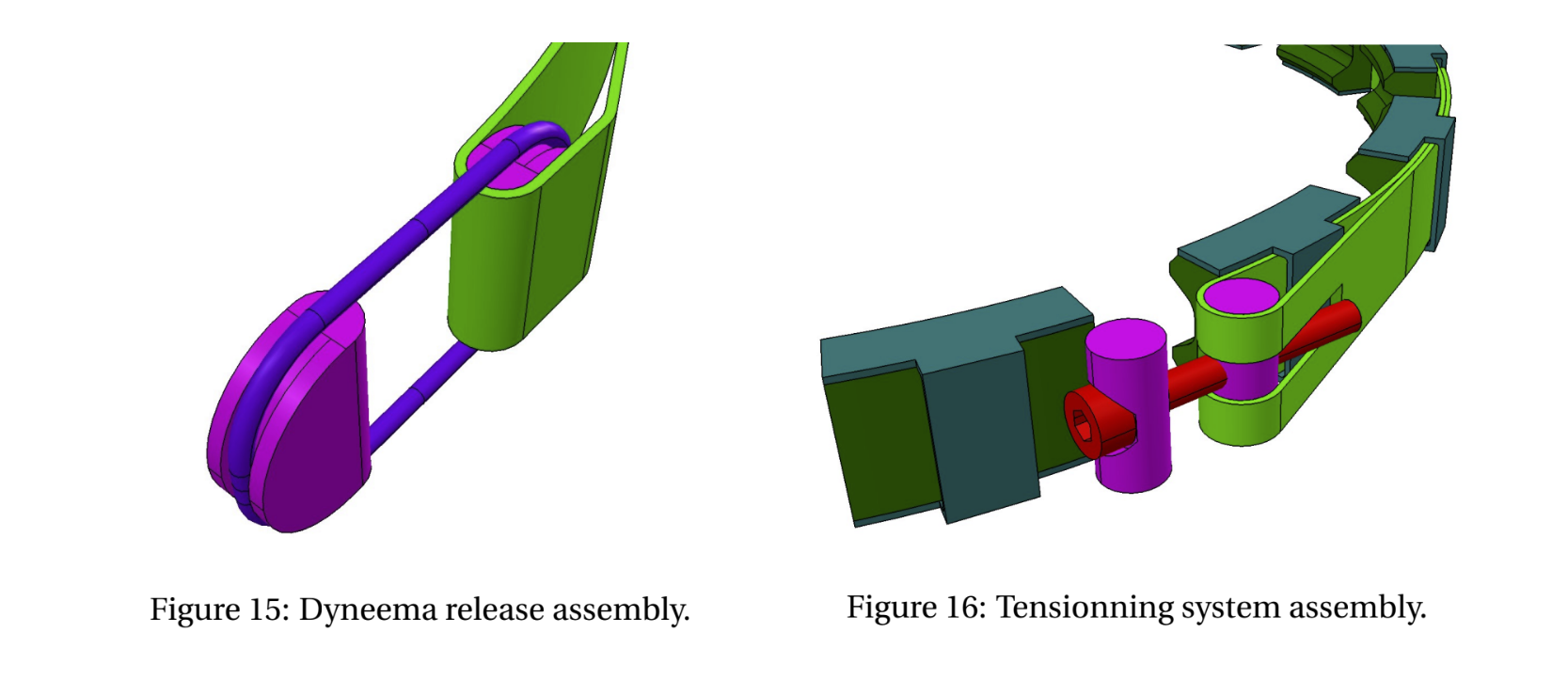

At the beginning of the pyrocutter development, several fundamental aspects were investigated to understand the feasibility and performance requirements of the system. The focus was on replacing the slower Dyneema cord burn-through mechanism with a compact device capable of severing an M3 screw in milliseconds, thus ensuring rapid and reliable separation.

The first stage of the study concentrated on geometry and scaling. Different projectile diameters (4 mm and 5 mm) were tested, along with several tip shapes (flat point, conical point). It was found that a chamber length of more than 20 mm was necessary to provide sufficient acceleration to the projectile. For a 5 mm projectile, a charge of approximately 0.45 g of black powder in an 8 mm reservoir was required to cut the screw reliably.

Parallel work was done on the reservoir and filling method. Two threading systems were explored to optimize powder loading and compression. The need for a 15 mm fuse length was also established, along with sufficient space in the reservoir to handle combustion pressure without failure. Proper sealing of the acceleration chamber and the projectile passage was critical to avoid excessive gas loss, which would reduce impact energy.

Projectile retention under vibration and acceleration was also studied, as premature movement could compromise reliability. Solutions such as rubber rings, glued combustible supports, or thin paper attachments were considered.

In terms of material choice, both steel and aluminum designs were fabricated. While steel allowed for robustness, aluminum was preferred due to its lighter mass and reduced damage to the system after firing. Early discussions also considered the potential for reusability by machining an ejection hole at the end of the chamber to recover the projectile.

Finally, inspiration from industrial parachute cutters guided the design choices, particularly in projectile shape and chamber proportions. Tests were planned under different environmental conditions (temperature variations, vacuum, vibrations, and inverted orientations) to validate reliability.

A pyrotechnic device that severs the Clamp Band to release the Upper and Lower Rings. This component is critical for ensuring rapid and reliable separation.

The Pyrocutter System consists of two pyrocutter devices positioned symmetrically on either side of the Clamp Band. Their mission is to sever an M3 screw, which is part of the Clamp Band tightening mechanism, upon receiving an electrical signal triggered after apogee detection. This action allows the Clamp Band to release and initiate the separation of the Upper and Lower Rings.

¶ Key Features

- Precise Cutting Action: Cleanly severs the M3 screw, enabling immediate release of the Clamp Band.

- Rapid Response: Cuts the screw within milliseconds of signal activation.

1st Design:

.png)

2nd Design:

.png)

¶ Main Specifications

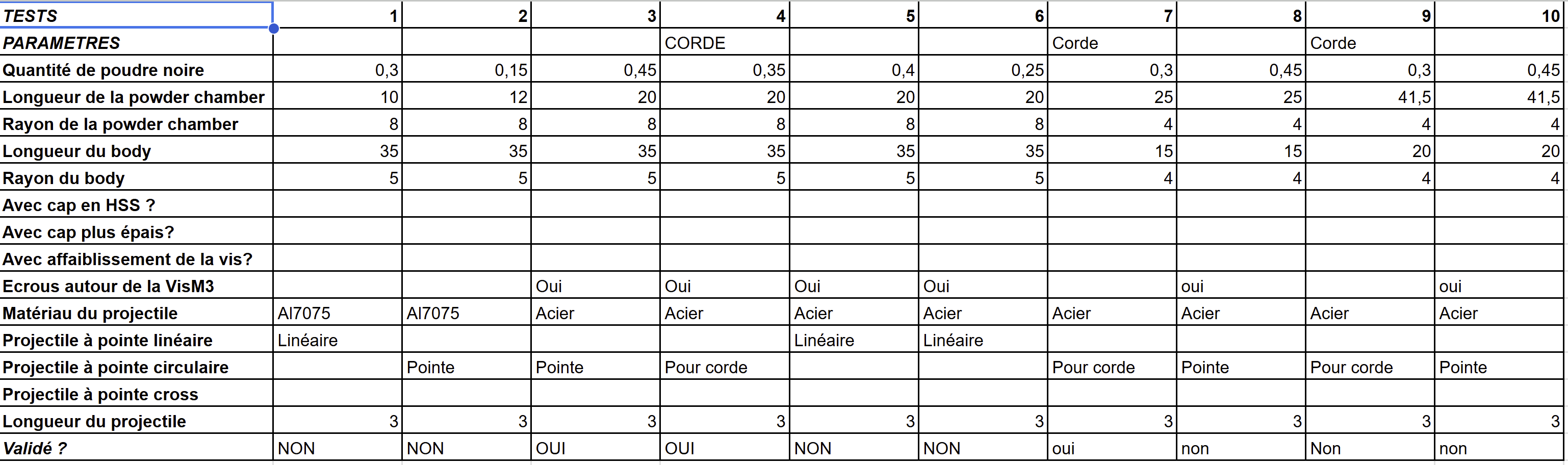

The objective of the pyrocutters experimentation conducted this semester was to optimize mass and size while producing functional models capable of cutting an M3 screw. Two models successfully cut a screw using 0.45 g of black powder. Various parameters were analyzed in an Excel file, including the dimensions of the pyrocutters, the shape of the projectiles (flat point, conical point, etc.), and the constraints applied by nuts. Details are available in the TSP.

The experimentation revealed that a body with an acceleration chamber of more than 20 mm was necessary to achieve sufficient acceleration of the projectile. A 5 mm diameter projectile required 0.45 g of black powder and a reservoir of 8 mm in diameter. For a 4 mm diameter projectile, more black powder and longer reservoirs were needed. Two different threading systems were tested to optimize the filling of the reservoir and the amount of powder.

The study of industrial parachute pyrocutters inspired the design of the projectiles, with a preference for the flat point, although the conical point is also functional. In the reservoir chamber, the black powder needs to be compressed, and the reservoir must contain a 1.5 cm long fuse while being spacious enough to handle the constraints without being overly disruptive. The passage hole for the projectile should have enough clearance to allow it to slide but not be too large to prevent gas escape, which would slow the projectile and compromise the cut.

To account for vibrations, accelerations, and decelerations, and to keep the projectile towards the bottom, several solutions have been considered: using a rubber ring, applying a combustible object glued with epoxy, or attaching the projectile to a paper glued to the pyrocutters' wall. The tests will begin under various conditions, on the ground, in flight, with varying temperatures, and also with tests under vacuum, upside down, and with vibrations.

The user has focused on several key aspects during the development of the pyrocutters, including the machinability of the projectiles, the shape and orientation of their tips for optimal cutting, reservoir sealing, gas decompression management, and the impact of the projectile’s size and length. The feasibility of a reusable pyro-cutter has also been explored. Currently, tests are being conducted on steel pyrocutters, featuring a small hole at the end of the acceleration chamber to allow for projectile removal after use.

To minimize potential damage to the pyro-cutter, the user considered using soft materials to slow down the projectile. However, it was observed that the screw absorbs most of the energy. Due to its mass efficiency and to reduce possible damage, aluminum is preferred for pyro-cutter production.

Example of diagrams or tables to collect datas from experimentations:

- Reliability Testing: Conducted multiple activation cycles to ensure consistent performance.

- Thermal Effects: Verified no adverse thermal impacts on surrounding components.

¶ Calculs de surface de contact du projectile