¶ Introduction

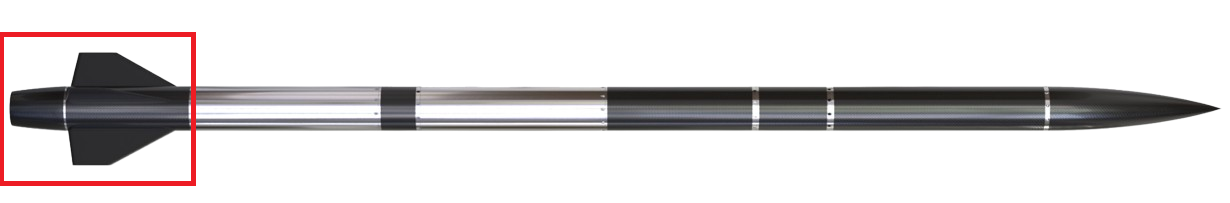

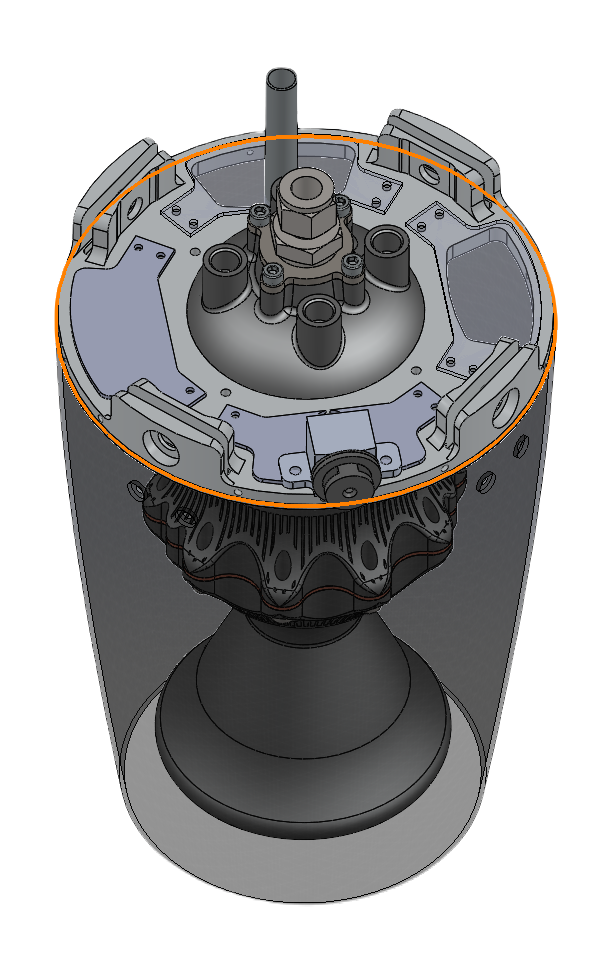

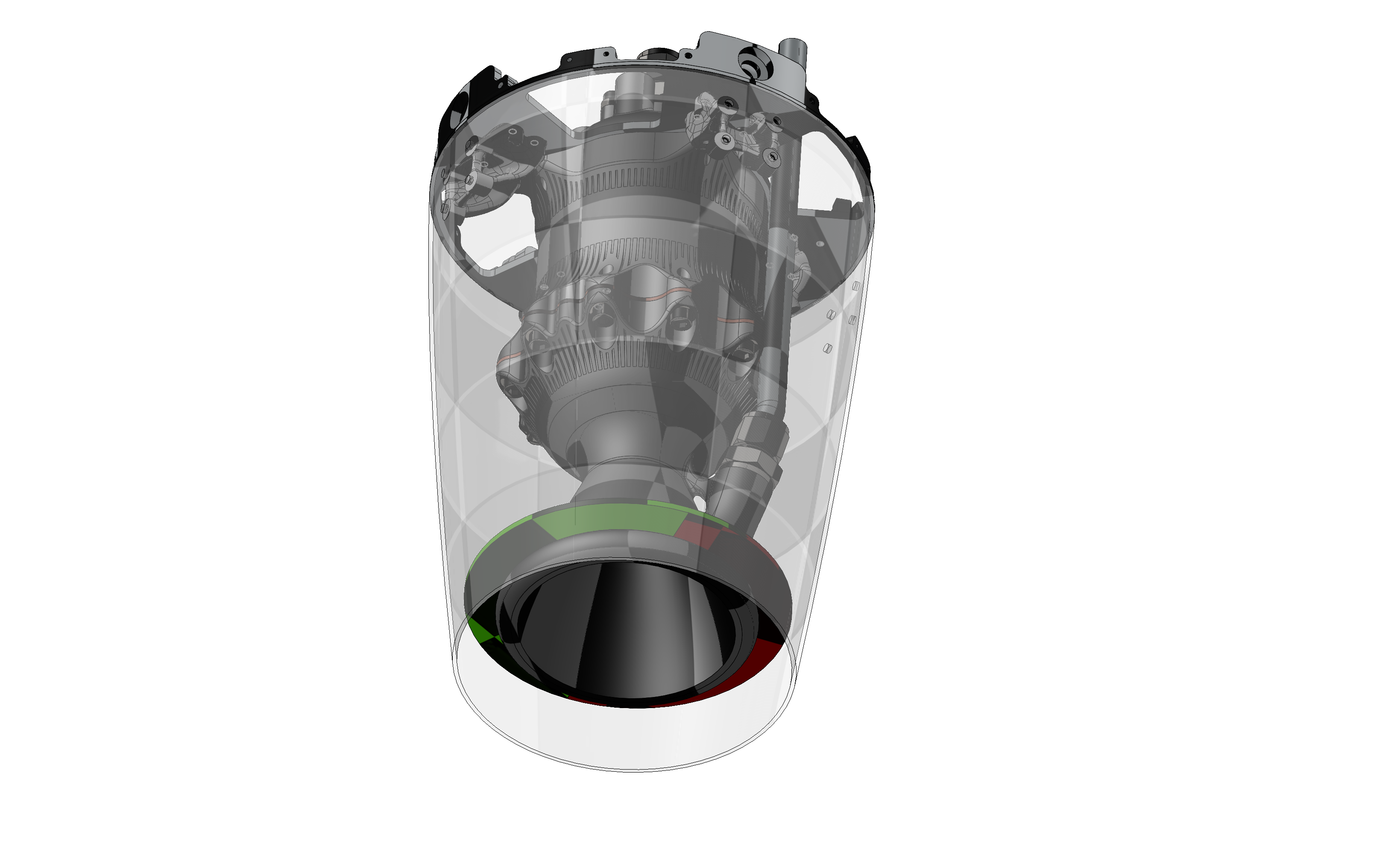

The Engine Bay is the main structure that integrates and transmits the thrust of Demo-B1 through the internal structure of Firehorn. It houses bi-liquid engine, extending from both tanks to the lower section of the rocket, where it connects to the combustion chamber, ending with the boattail.

It therefore requires a particular emphasis on simulations and optimization due to the shear amount of forces experimented by the assembly during flight, and evidently, as a failure of any kind in one of the components of in this sub-assembly would compromise Firehorn flight trajectory.

¶ Definitions and Abbreviations

- Engine bay : EB

- Thrust plate : TP

- Boattail : BT

- Retractable Rail buttons : RRB

- Factor of Safety : FoS

- CFD : Computational Fluid Dynamics

¶ Relevant Documents

¶ Relevant Knowledge Needed

¶ Design Guidelines :

- Achieve the best stiffness to mass ratio in all of the components with some hefty safety margins through static load simulations and topology studies (Thrust_Plate, Exhaust_Shield). Therefore the FoS should not be too high, which would result in an overkilled system with a too high mass, but it can't be too low either. Usually we used FoS of 2 to 3.

- Reduce the flight drag as much as possible by optimizing the airflow going around the tail of the rocket body (Boattail). This is even more critical due to the Firehorn’s supersonic speed.

- Withstand the extreme temperatures caused by Demo-B1’s plume heat radiation (Boattail)

- Develop a design for each component while ensuring confidence in the feasibility of manufacturing, taking into account realistic costs and complexities.

- Bonus : Make use of state-of-the-art technologies such as generative design and metal additive manufacturing to optimize certain components that could benefit from them (Fixation_Tree, Thrust_Plate).

¶ Requirements and Design Criterias

These are main requirements that guided us through the conception of the current version of the BT.

- 2024_C_SE_ST_ENGINE-BAY_REQ_03 Engine bay total length

The ENGB shall have a total lenght of [850][+/-40]mm - 2024_C_SE_ST_ENGINE-BAY_REQ_04 Bay length

The ENGB shall have a bay length of [600][+/-20]mm - 2024_C_SE_ST_ENGINE-BAY_REQ_05 Boattail length

The ENGB shall have a boattail length of [250][+/-20]mm - 2024_C_SE_ST_ENGINE-BAY_REQ_06 Inside access

The ENGB shall allow for a human hand to access the valves inside. - 2024_C_SE_ST_ENGINE-BAY_REQ_09 Fins loads bearing

The ENGB shall sustain the loads produced by the fins on its structure. - 2024_C_SE_ST_ENGINE-BAY_REQ_11 Engine bay structure mass

The total mass of the ENGB structure shall be [6000][+/-600]g. - 2024_C_SE_ST_ENGINE-BAY_REQ_12 Structure type

The ENGB structure shall be internal so that its inside may be radially accessed. - 2024_C_SE_ST_ENGINE-BAY_REQ_13 Exhaust Isolation

The ENGB structure shall isolate the engine exhaust from it's internals - 2024_C_SE_ST_ENGINE-BAY_REQ_14 Boattail Thermal Protection

The boattail design shall avoid thermal damage from the engine exhaust and radiation - 2024_C_SE_ST_ENGINE-BAY_REQ_15 Engine Shock Protection

The boattail shall protrude at least [20]mm rearwards of the engine nozzle's end

¶ Main Design Options for the Engine Bay Assembly

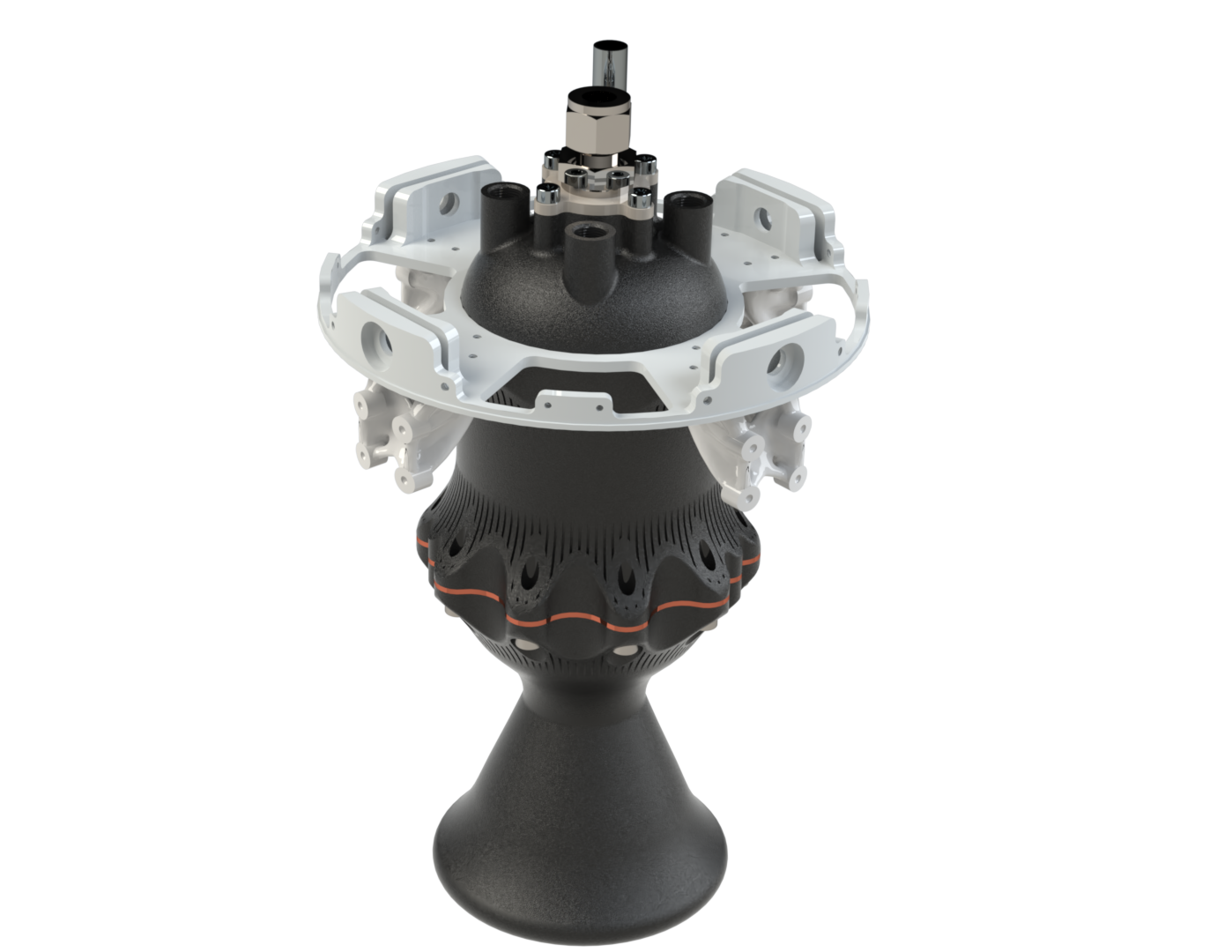

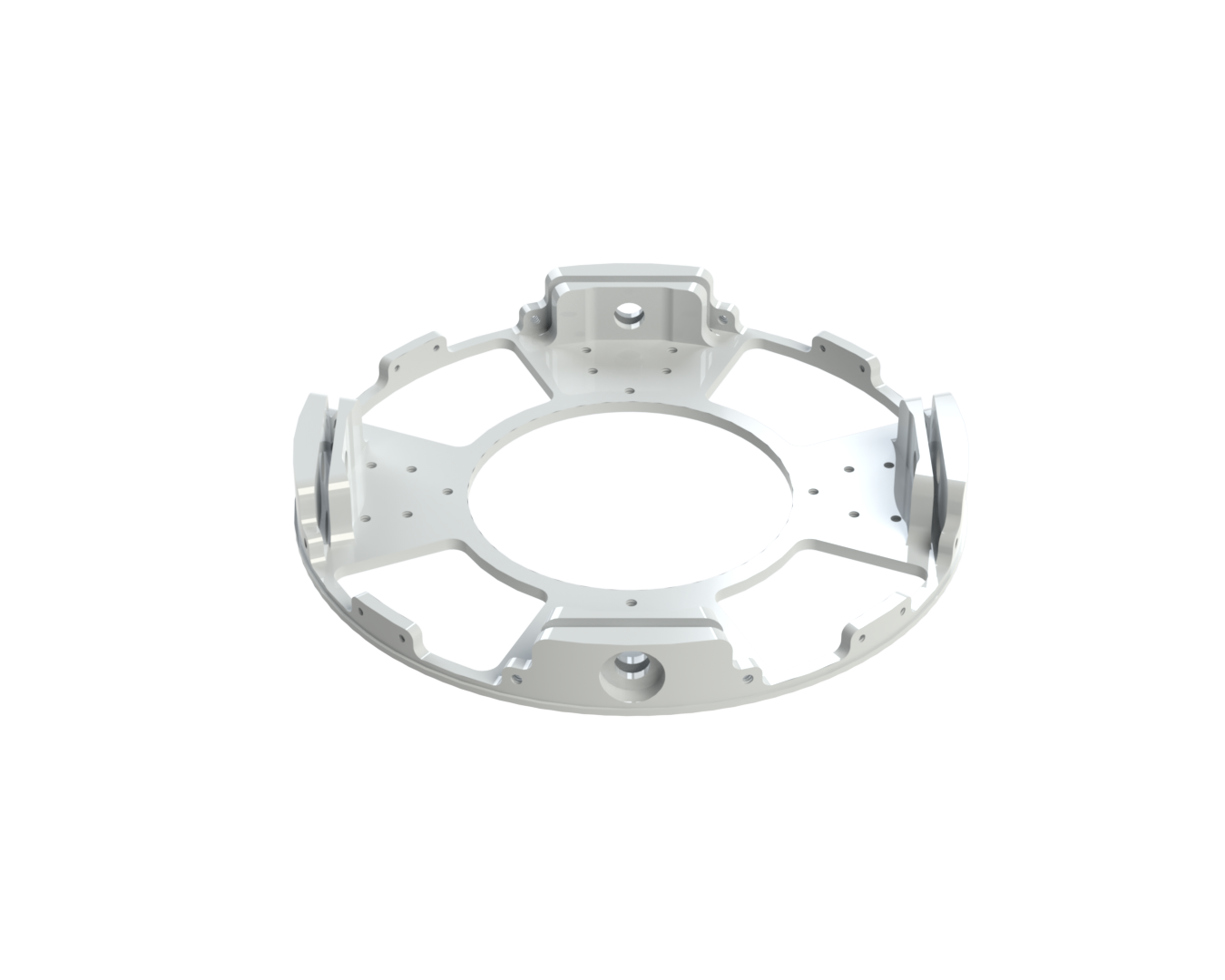

Our initial design closely resembles the Nordend Rocket from before, primarily consisting of the Thrust Plate, the end-ring, and the fixation ring connected to the end-ring. The end-ring and fixation ring serve the purpose of securing the Retractable Rail buttons and the Boattail to the rocket.

Has been done previously,

TP less complex because of fewer components fixed on it

Heavy,

more components

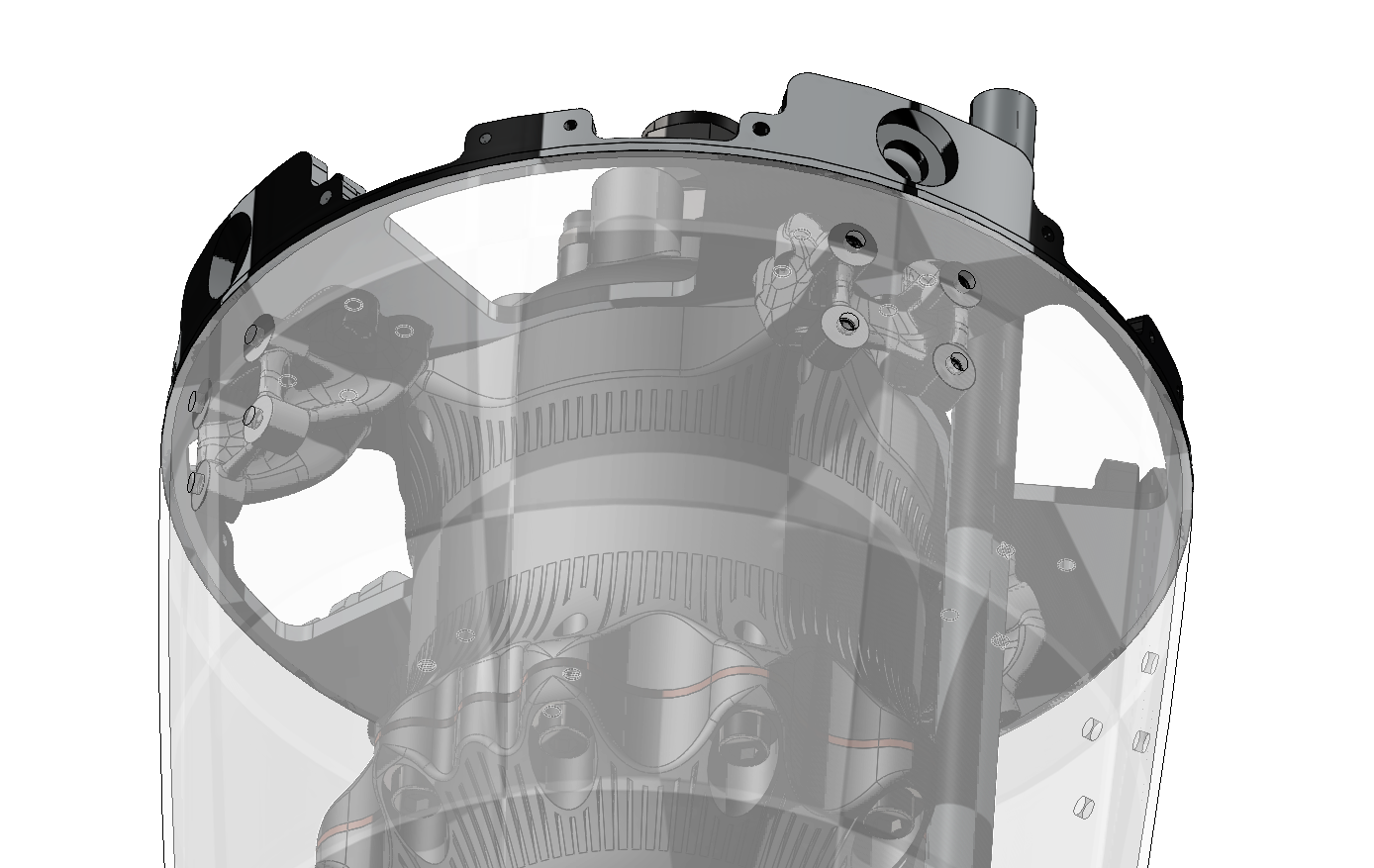

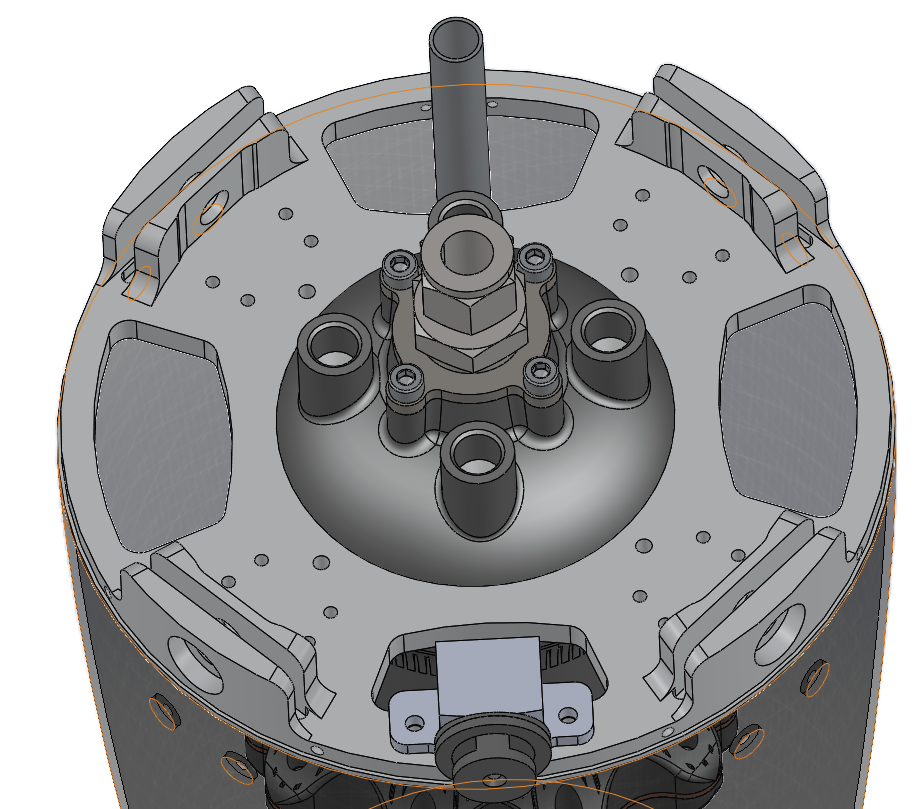

In our second design, we opted to merge the previous Thrust plate, End Ring and Fixation plate into one part (+ the 4 Fixation trees). The new Thrust plate is responsible for supporting not only the engine but also the Retractable Rail buttons and boattail. This became possible due to the larger diameter of Firehorn compared to Nordend. This fusion represents a significant reduction in both weight and complexity. The connection to the boattail is achieved through the use of four fixation trees.

Significant weight and volume reduction,

Easier integration and manufacturing,

Drag reduction because of longer Boattail,

Easier integration of the RRB

TP more complex, (but should still be manufacturable with a 3 axis CNC)

¶ Narrowing the Design Options

The single-stage EB design having considerable advantages compared to the previous dual-stage EB design, we concentrated our research and design optimisation on the single stage design. A month worth of research was still done on improving the dual stage design, but will not be mentioned in the following paragraph since the design is quiet similar to Nordend

¶ Design Recap :

Function : Translates the engine load through the entire rocket.

Force : Axial : 5kN was designed only for 9km version

Safety factor : 2

Design method : Same design as Nordend. Topological optimization studies and static load simulations to determine optimal dimensions.

Validation : FEM, and will be tested during a cold and a Hotfire test.

Manufacturing method :

-

Option 1 : 3D printed out of Aluminium 7075-T6 (?)

-

Option 2 : 3/5 axis CNC out of Aluminium 7075-T6.

Comment : More details can be found here 2024_C_ST_THRUST-PLATE_DJF

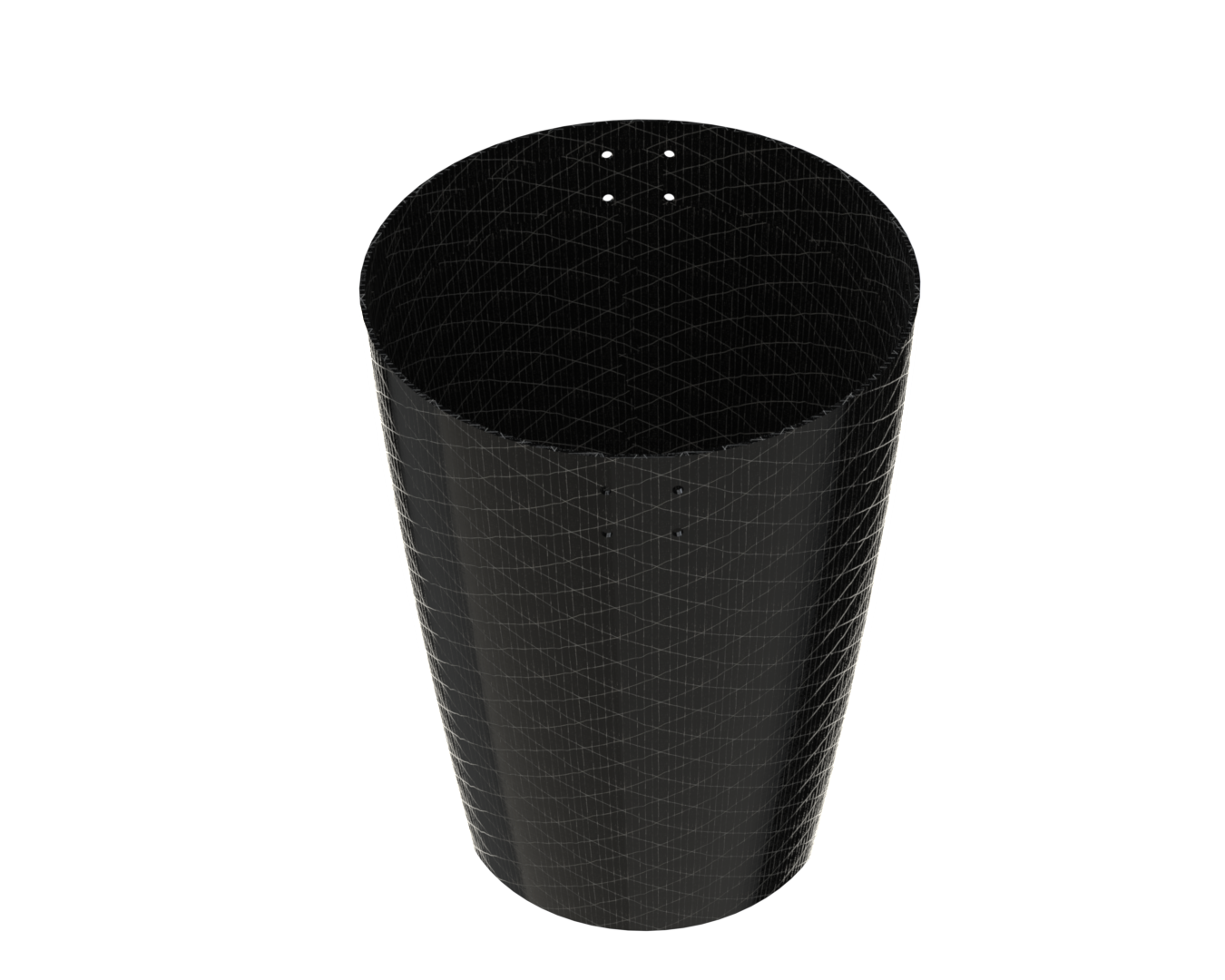

Function : Protect engine and structure from ground impact ; reduce wake drag behind the rocket ; holds the wet weight of the rocket.

Maximal expected Force :

- weight due to gravity (around 100kg) with a FoS of 2.

- impact at landing (not considered because Boattail is considered as a consumable)

- thermal load from engine (simulation will be done in the future, and we consider adding a reflective protection layer to the inside of the boattail.)

Design method : LD Sears-Haack equation for the shape.

Validation : FEM and CFD will be performed in the future

Manufacturing method : - Mold carbon layers draped around then heated in an oven. Same method as with previous Nosecone

Lightweight

harder manufacturing because of non linear geometry.

- 3D printed, high and low temperature resistant carbon-reinforced nylon (same as Nordend).

Easier manufacturing

Comment : More details can be found here 2024_C_ST_BOATTAIL_DJF

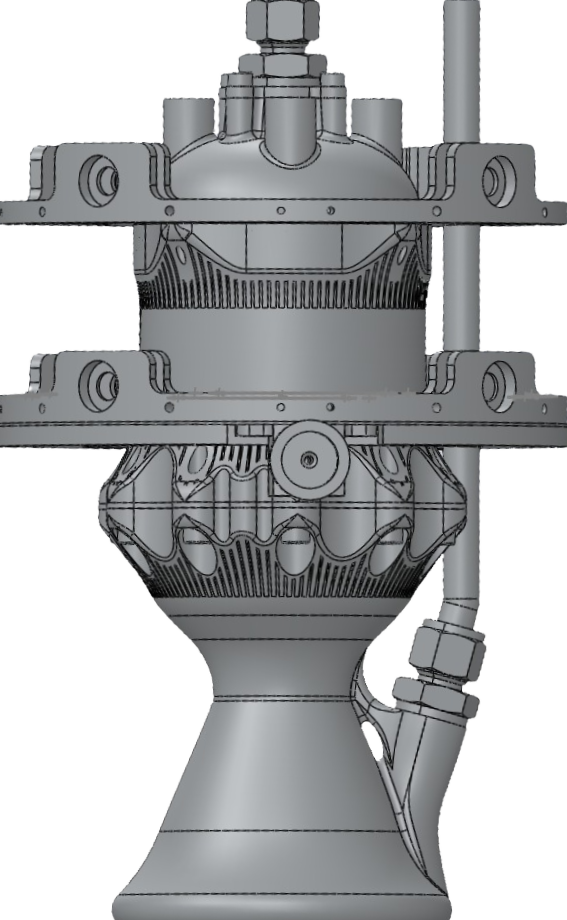

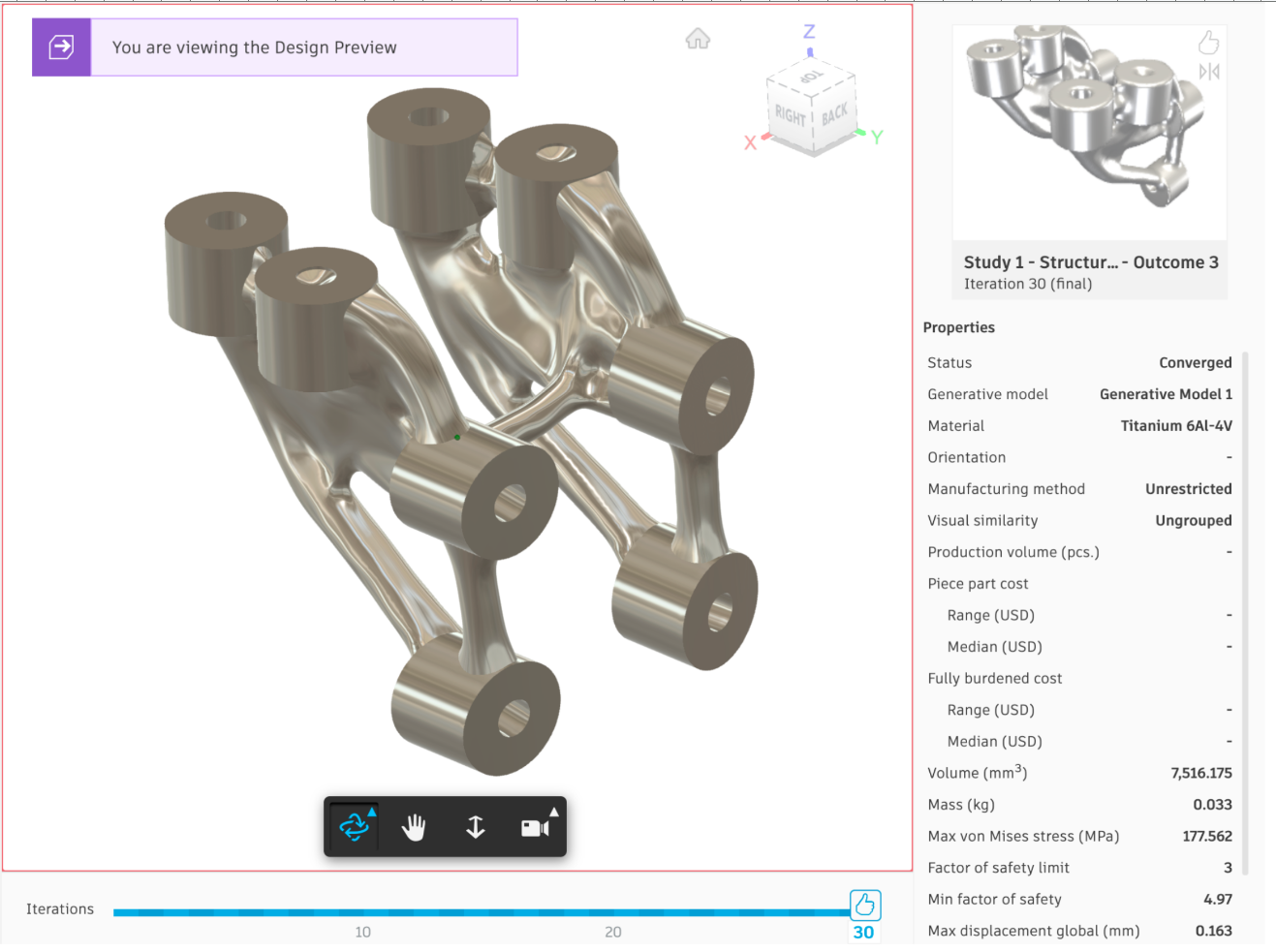

Function : The Fixation_Trees are the main component that fixates the boattail to the rocket through the TP. Multiple versions have been made of this part, each iterating on the amount of fixations to the TP and to to the BT.

Maximal expected Force :

4500 N Normal force distributed between the surfaces in contact with the boattail

-1670N Z-force distributed between the surfaces in contact with the Boattail

X-Y-Z constraints on the fixation holes attached to the Thrust_Plate (for the simulation)

Design method : Generative shape design with Fusion. They will be fixed with 4 M3screwss to the TP and with 2

Validation : FEM.

Manufacturing method :

- 3D metal printing

Function : To protect inner structure (engionics, valves...) and the Boattail from hot exhaust gaz.

Different designs :

- Design 1 : alu_sheet_TP

Easy to produce, lightweight, easy to assemble

Does NOT protect BT from melting

- Design 2: Half-ring assembly

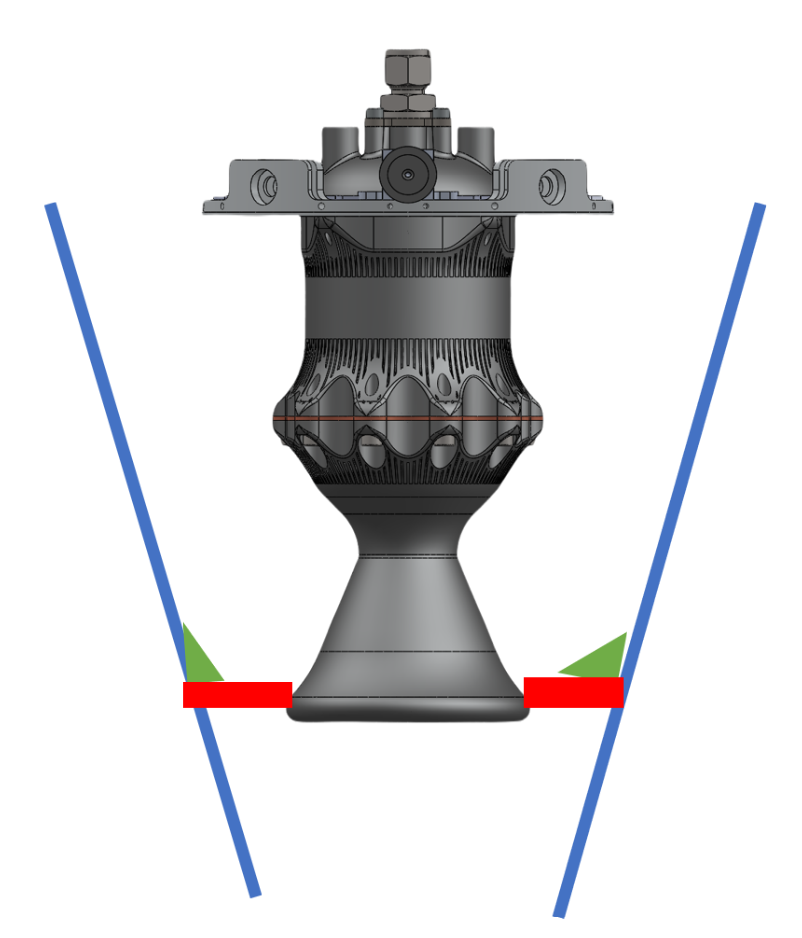

This design consist of 2 halfs that are thinner on both ends so that they can be supperposed and glued inside the boattail. One half is indicated in red, while the other one is in green. The utilization of half rings is imperative due to the nozzle exit diameter's enlargement towards the exit. Further exploration of optimal shapes and patterns for connecting both ends is planned for the upcoming week.

2 ideas to fix both half rings to the Boattail have been though off. The first idea is to simply glue it to the boattail. The second idea is to use 4 triangular shapes that are glued to the boattail (and/or screwed to the halfrings). They would increases the glued surface and therefore solidify the assembly (see the following scheme).

We also consider using Alu Tape to reflect heat.

Good thermal protection : protects the Boattail

Harder to assemble

Comment : Further research needs to be done on Design 2. Thermal protecting tape would also put on the inner surface of the BT.

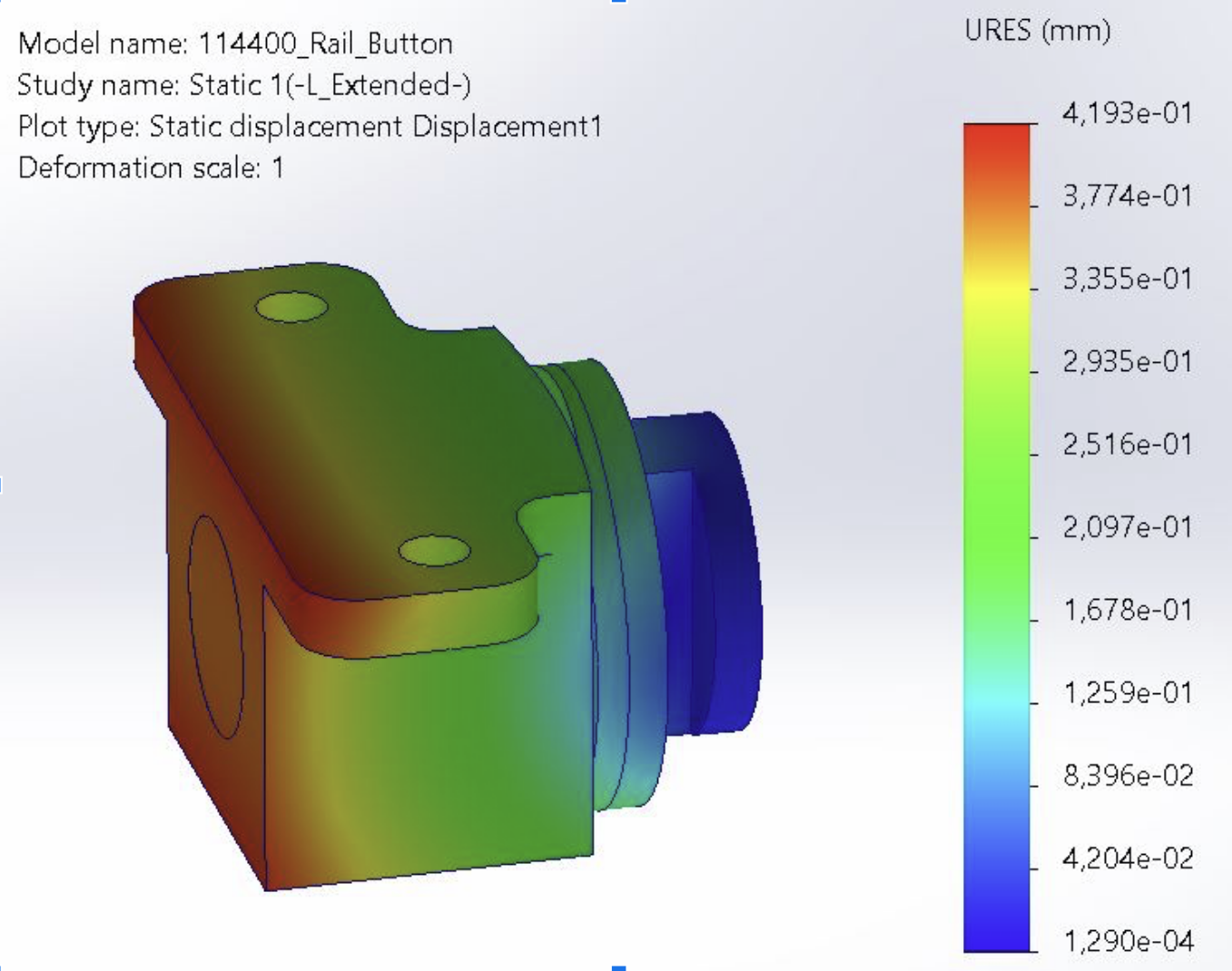

Function : Guide the rocket on the launch pad through the launch rail. The RRB are retractable, which reduces the drag during flight.

Design method : The RRB are the same as Nordend. For the single stage design (outdated) they were supposed to be fixed to the ER. For the current design, they are fixed on the TP with 2 M4 screws.

Validation : FEM which proved that Nordend's dimensions are also sufficient for firehorn's load.

Comment : More details can be found here 2023_ST_AP_H01