¶ Introduction

¶ Purpose, Objective and Scope

The purpose of this document is to report on the pressure tests performed on the tanks in order to qualify them.

¶ Applicable and Reference Documents

¶ Requirements to be verified

- 2024_C_SE_ST_TANK_REQ_09 Tank yield pressure

The tank shall not yield under an internal pressure of [90]bars for [30] minutes.

¶ Test Report

The two identical pressure vessels were subjected to a pressure test. Both vessels have the same design and were manufactured from 6082-T6 aluminum alloy. Each vessel has a nominal capacity of 16 liters and a nominal pressure of 60 bar.

In accordance with SRAD requirements, the test pressure must be set at 1.5 times the nominal working pressure, i.e., 90 bar.

¶ Test Procedure

The tests were carried out using a hydrostatic pressure method. The procedure was performed in two stages:

¶ 1. Intermediate Pressure Test

- Pressure was increased gradually to 60 bar.

- The pressure was held for 10 minutes.

- Depressurization followed by external visual inspection of the vessel.

- Acceptance criteria: pressure loss

< 0.1 bar/minand no leakage detected during inspection.

¶ 2. Proof Pressure Test

- The pressure was further increased up to 90 bar.

- The pressure was held for more than 15 minutes.

- Acceptance criteria: identical to the intermediate test.

Both tests were performed sequentially on each vessel.

¶ Results Analysis

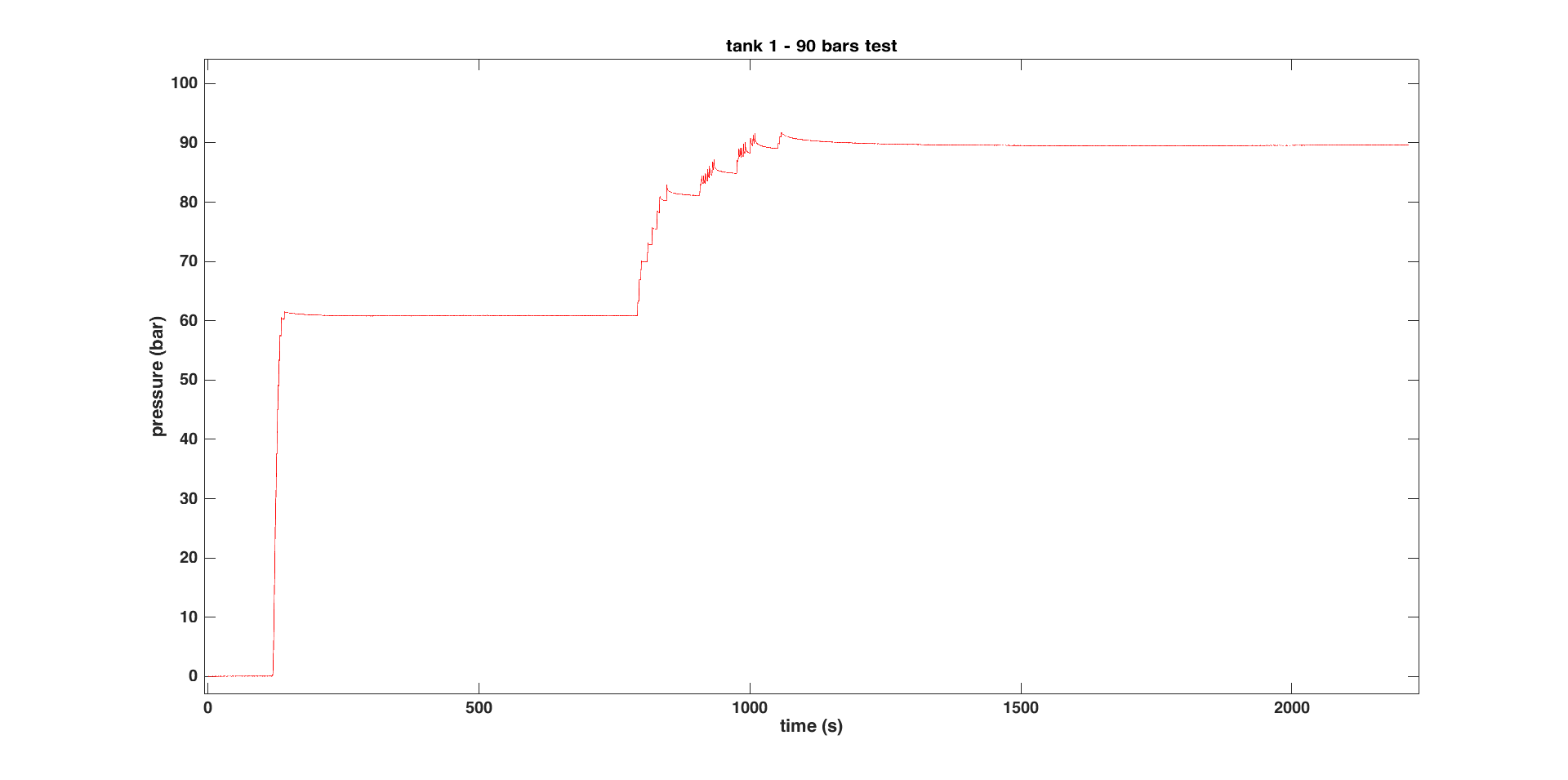

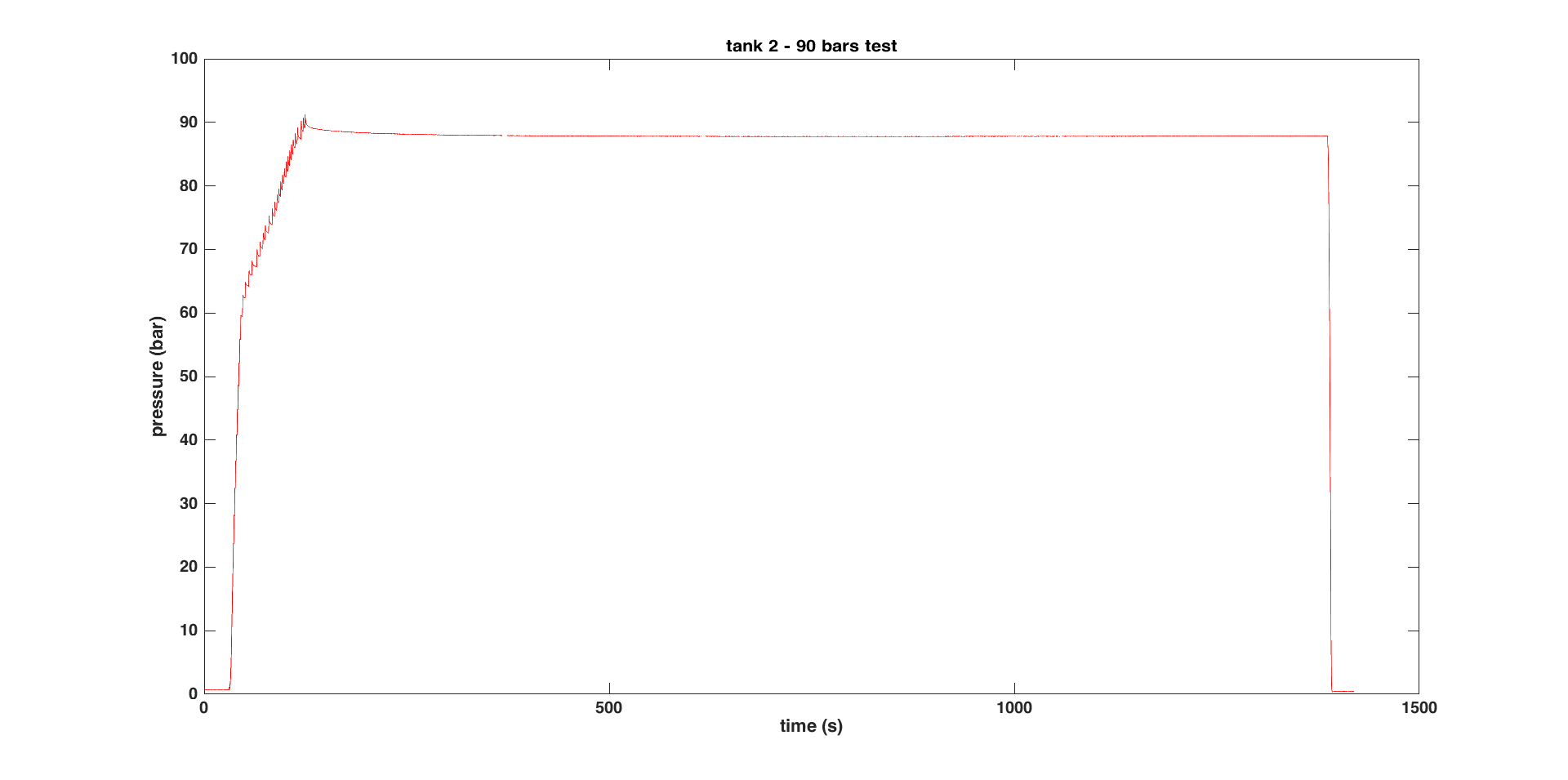

The pressure-time recordings correspond to the 90 bar pressure test for both vessels. The graphs provide a detailed view of the pressurization, pressure stabilization, and depressurization phases.

For the first vessel:

- The pressure was first increased to approximately 60 bar, then to 90 bar.

- Once stabilized at 90 bar, the pressure remained constant for more than 17 minutes.

- The observed pressure drop was below the acceptance threshold of 0.1 bar/min.

- No leaks or major deformations were detected.

✅ The test was considered successful.

The second vessel was pressurized to 90 bar after passing the 60 bar test, which does not appear on the graph. In the first few minutes after reaching 90 bar, a slight relaxation occurred, stabilizing the pressure at around 88.4 bar. This relaxation corresponds to the accommodation or deformation of the vessel walls under load. The official 20-minute holding period was counted after this relaxation, once the pressure had stabilized at 88.4 bar. During this phase, the pressure remained stable and the loss rate was well below the acceptance limit of 0.1 bar/min, at 0.037 bar/min. Despite the slight overshoot and the expected relaxation behavior, the second vessel fully met the acceptance criteria and no leaks or structural problems were detected.

In conclusion, both aluminum 6082-T6 vessels successfully passed the 90 bar proof pressure test. The minor relaxation observed in Tank 2 was consistent with the expected mechanical accommodation of the material and does not indicate a defect. The results confirm that both vessels meet SRAD acceptance requirements and demonstrate reliable structural integrity under proof loading conditions.