¶ Introduction

¶ Purpose, Objective and Scope

The purpose of this document is to present the pressure test that led to the explosion of one of the tanks.

¶ Applicable and Reference Documents

¶ Requirements to be verified

- 2024_C_SE_ST_TANK_REQ_09 Tank yield pressure

The tank shall not yield under an internal pressure of [90]bars for [30] minutes.

¶ Test Report

¶ Test Results

¶ Data Analysis

Before the proof pressure campaign, a burst pressure test was carried out on an earlier prototype of the vessel in order to assess its ultimate strength and identify potential weaknesses. Unlike the final design, this prototype had a capacity of 25 L and was manufactured with a similar geometry and welding approach. The target burst pressure, according to design requirements, was 120 bar (equivalent to 2.0 times the nominal working pressure of 60 bar).

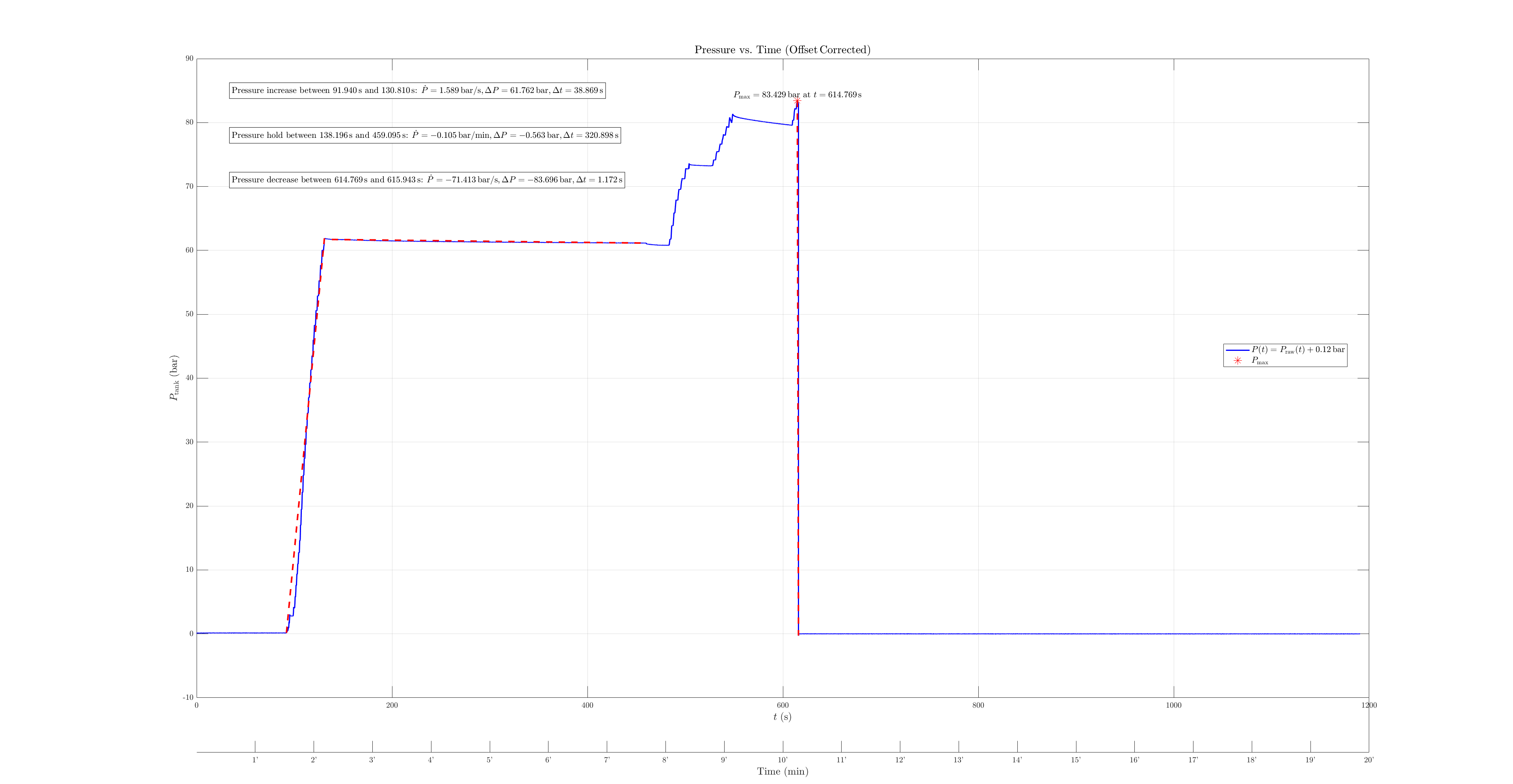

The test was conducted hydrostatically by gradually increasing the internal pressure until catastrophic failure occurred. The pressure evolution was monitored and recorded throughout the loading phase up to the point of rupture.

The vessel failed at a pressure of 83.43 bar, which is significantly below the expected burst pressure of 120 bar. This corresponds to only 1.39 times the nominal working pressure, insufficient compared to the required safety factor of 2.0.

The abrupt failure suggests a localized structural weakness rather than a gradual loss of integrity. Post-test inspection confirmed that rupture initiated at the weld seams, making weld quality and geometry the primary limiting factors in this prototype.

This outcome clearly highlighted a structural deficiency linked to weld design and fabrication. The premature failure demonstrated that the welding process was not optimized for strength, particularly in relation to penetration, heat-affected zones, and local stress distribution.

¶ Reason of failure

We believe that the causes of failure are as follows:

-

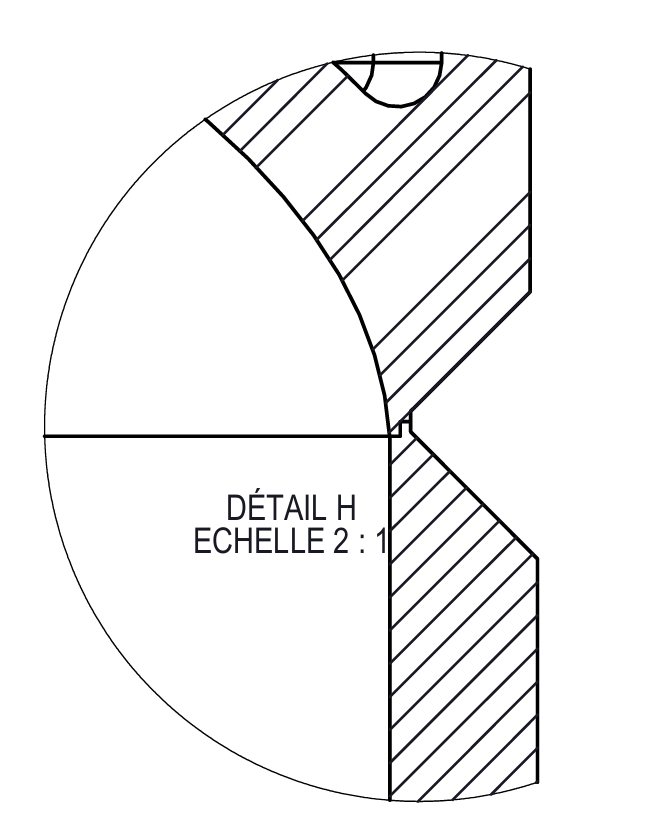

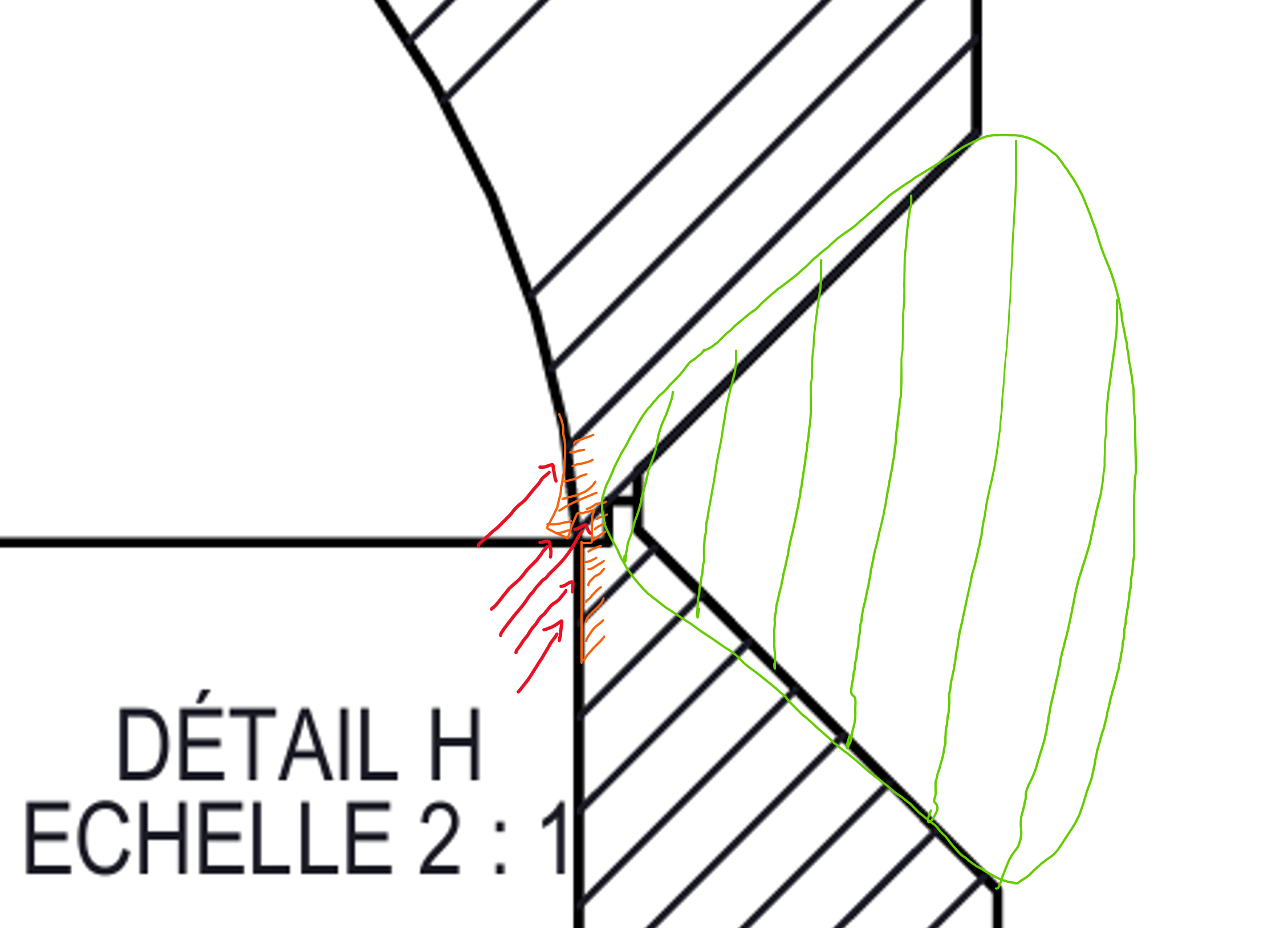

The interface between the caps and the tube was a short center (caps fitting into the tube). Although this interface allows for good alignment between the parts, it does not allow for good weld penetration. Worse, the inner lip of the caps can lift up and create a crack.

|:------:--------

| |

| |

| -

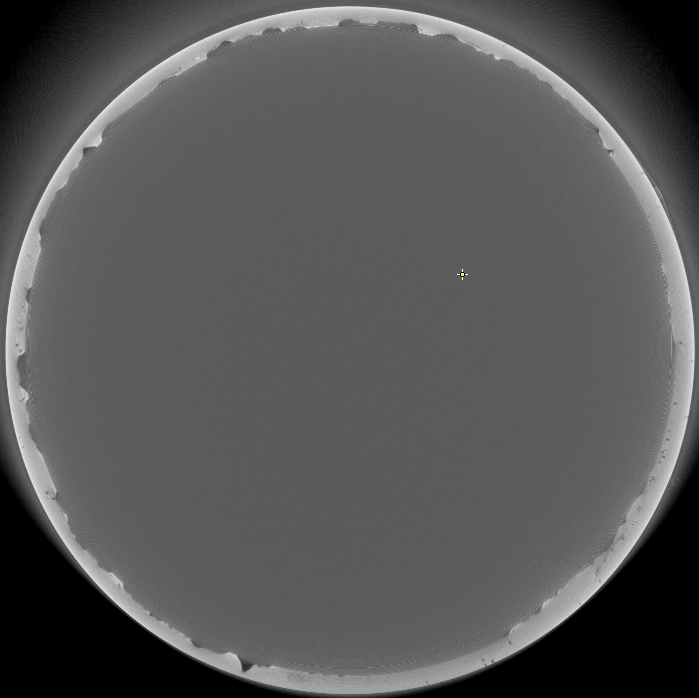

The welds were of poor quality. They were not uniform, were porous, and had inclusions that probably led to the initiation of cracks.

|:------:--------

| |

| |

|

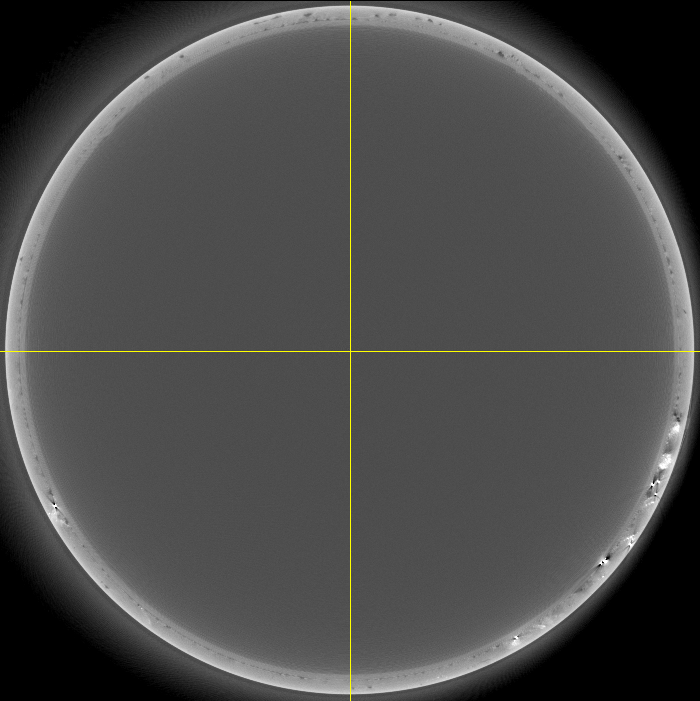

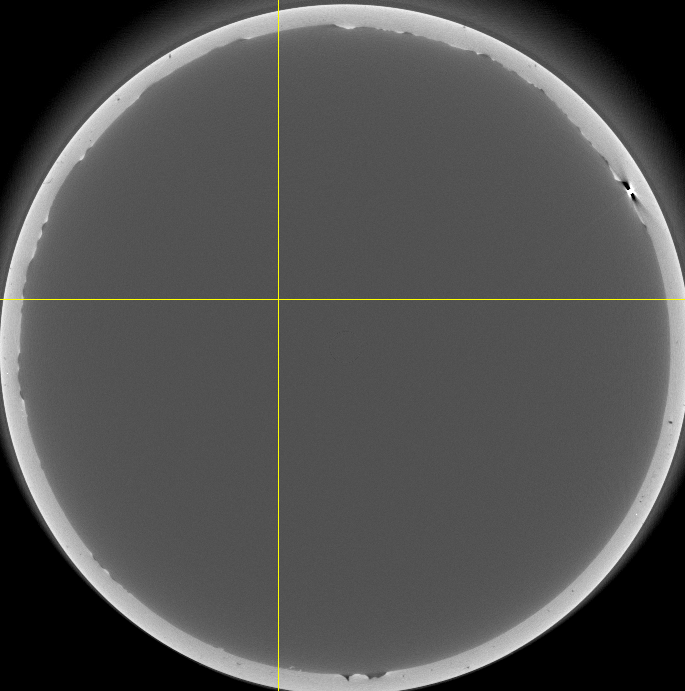

|Weld A of the tank that did not explode|Weld B of the tank that did not explode|

|:------:--------

| |

| |

|

|Weld A of the tank that exploded|Weld B of the tank that exploded (failure of this weld)|

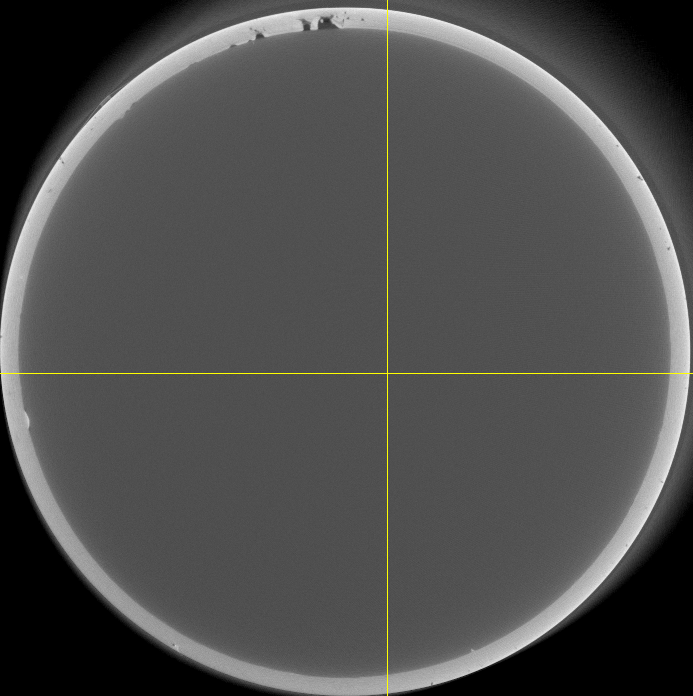

During pressure testing, several leaks appeared on both tanks. In order to fix them, re-welding was carried out.

|:------:--------

| |

| |

|

|Re-welding|Porosity|

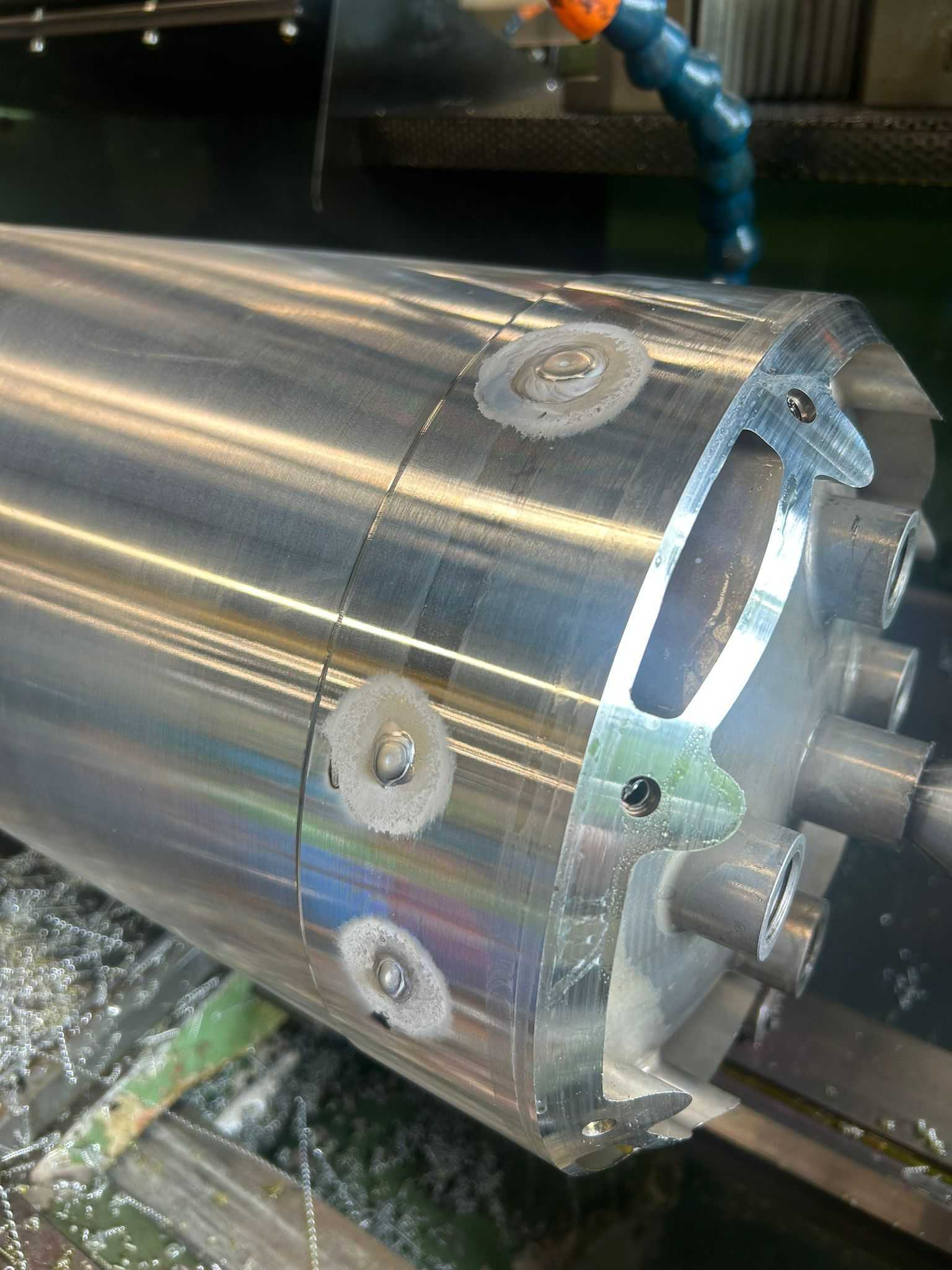

- The third potential cause could be that the weld is in the position where internal stresses are highest.

|:------:--------

| |

| |

|

|||

¶ Possible Improvments

The lessons learned from this burst test directly influenced the final design of the 16 L vessels that later underwent successful proof pressure testing.

The main improvements implemented between this iteration and the final version were:

- Relocation of welds away from areas of high stress concentration.

- Modification of the weld interface to maximize penetration and improve joint strength.

- Enhanced welding quality through the use of a turning fixture, ensuring constant weld geometry and uniform deposition.

- Increased wall thickness to provide higher structural margins.