¶ Introduction

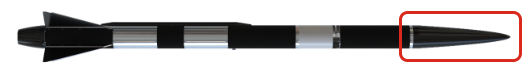

The purpose of this document is to define the design of the Nosecone, a fundamental component of the rocket and the arangement of the Nosecone_Bay.

This document will also address the ST-PL interface within the Nosecone_Bay.

However, the manufacturing steps and simulations are not included in this document.

¶ Applicable and Reference Documents

The documents listed below provide additional context to the technical definition of the Nosecone. They cover manufacturing methods, critical thermal parameters, and functional objectives related to this component.

¶ Requirements

- 2024_C_SE_ST_REQ_08 LV inside diameter

The LV shall have an internal diameter of maximum [240]mm. - 2024_C_SE_ST_NOSECONE_REQ_03 Nosecone design responsability

The nosecone design shall be provided by FD. - 2024_C_SE_ST_NOSECONE_REQ_04 Nosecone length

The nosecone shall have a maximum length of [1000]mm. - 2024_C_SE_ST_NOSECONE_REQ_10 Nosecone curved length

The nosecone portion that is curved according to the design given by FD shall have a length of at least [960]mm. - 2024_C_SE_ST_NOSECONE_REQ_07 Nosecone structure mass

The total mass of the Nosecone structure shall not exceed [3200]g.

- 2024_C_SE_ST_NOSECONE_REQ_01 Nosecone declaration of purpose

The nosecone of the LV shall reduce the drag of the LV. - 2024_C_SE_ST_NOSECONE_REQ_09 Thermal resistance

The nosecone shall be able to resist the maximal temperature encountered during ascent of [TBD]K.

- 2024_C_SE_ST_NOSECONE_REQ_02 Nosecone declaration of purpose

The nosecone of the LV shall host the PL. - 2024_C_SE_ST_NOSECONE_REQ_05 PL integration

The nose cone shall be able to integrate a PL of the CubeSat standard [RD01] within the 3U format.

¶ Interfaces

The Nosecone primarily interfaces with the Payload system through a series of specific mechanical and functional connections:

¶ Interface ST_PL

- ⬛Physical interface:

The Nosecone is directly attached to the Payload Bay.

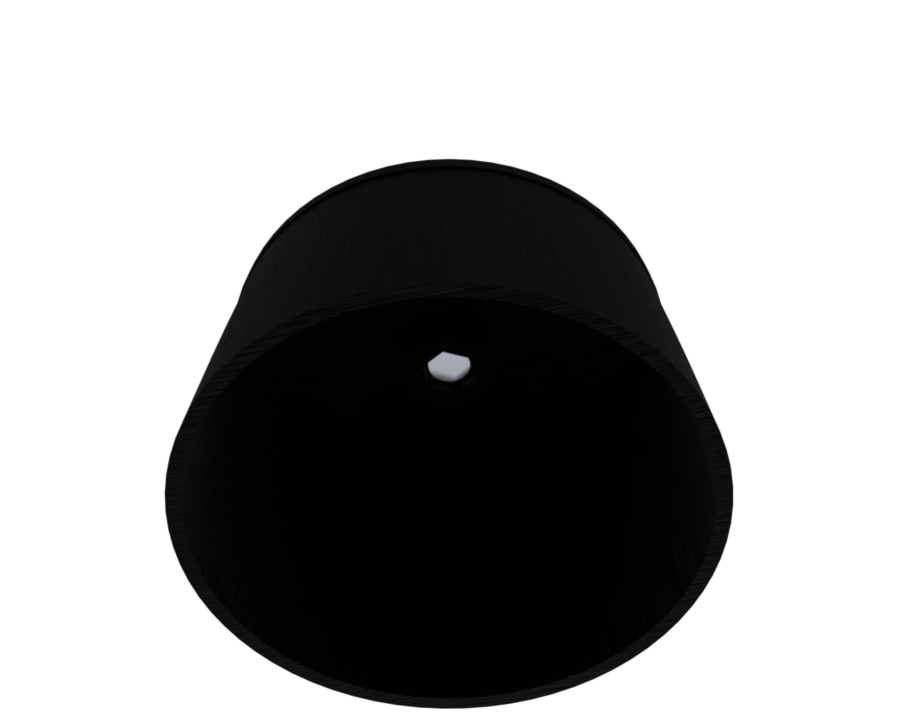

A dedicated hole through the Nosecone allows screwdriver access to switch on the payload from outside the module.

¶ Interface ST_ST

- ⬛Physical interface:

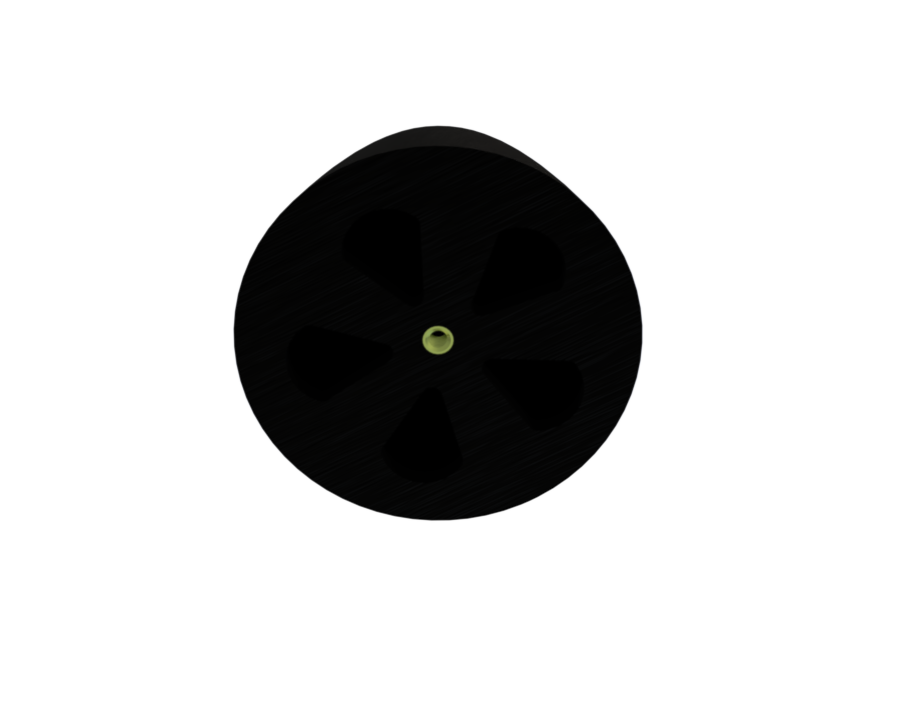

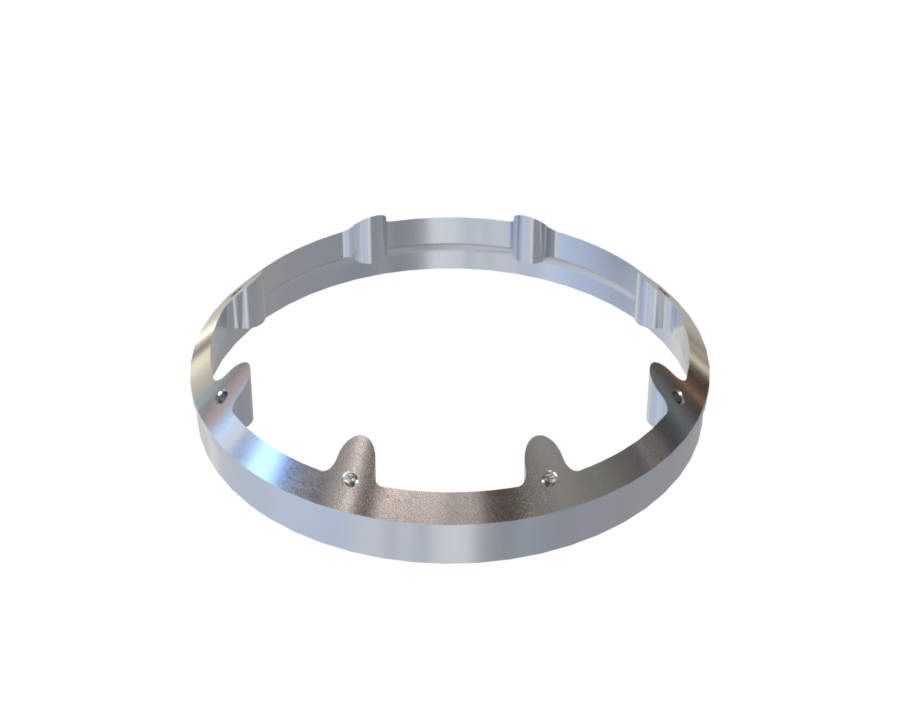

A male glued coupler is bonded inside the Nosecone to ensure structural attachment to the rest of the rocket.

A spacer is integrated to maintain the correct positioning of the 3U payload brick inside the Nosecone.

These interfaces are critical to ensure proper alignment, secure attachment, and the reliable triggering of the recovery or separation system during flight.

¶ Overview

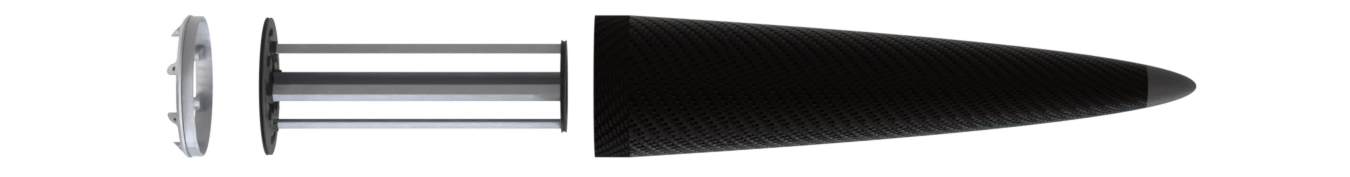

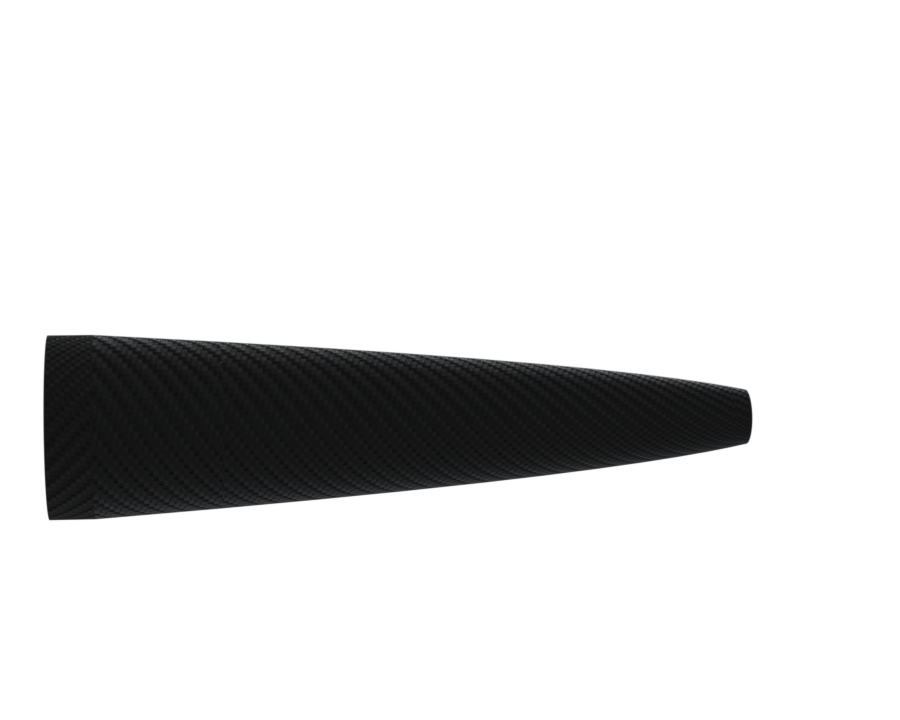

The Nosecone is a conical carbon fiber composite part, manufactured using vacuum prepreg procedure on a PET CF mold. Its front end incorporates a modular, removable tip system, optimize for mass efficiency and easy interchangeability in case of damage.

We therefore have multiple parts:

¶ Parts Description

¶ Description

The nosecone is divided into two parts:

- The first part is a cylindrical section measuring ... mm and 239.8 mm in diameter

- The second part is a quasi-conical section, whose equation is:

¶ Main Specifications

| Specification | Value | Unit |

|---|---|---|

| Dimensions | 1081.09 | mm |

| Manufacturing | Drapage prepreg | — |

| Material | Composite carbone | — |

¶ Interfaces

-

Interface with PET-CF Tip:

Flange at the edge of the Nosecone for fitting and bonding the tip. -

Interface with Payload:

Includes a passage for a screw switch and a bonded male coupler with a spacer for payload alignment.

No direct electrical or thermal interface.

¶ Description

The tip is 3D-printed from PET-CF, positioned at the apex of the Nosecone. It is removable and attaches mechanically with a screw.

The tip is non-structural, designed primarily for aerodynamic continuity and visual consistency, and does not contribute to load-bearing functions during flight or recovery.

It is a consumable that can be replaced at any time in case of breakage.

¶ Main Specifications

| Specification | Value | Unit |

|---|---|---|

| Manufacturing | FDM - Prusa Pro | — |

| Material | PET-CF | — |

| Fastening | Filetage intégré | — |

| Cost | 20 | CHF |

¶ Interfaces

-

With Nosecone Shell:

The tip includes a 3D-printed insert.

Inside the nosecone, an intermediate shell is bonded to its inner surface :

A screw is mounted on this shell, mechanically locked against rotation and axially retained using blue epoxy.

This configuration allows the tip to be threaded onto the screw, ensuring firm contact with intermediate shell. -

With Composite Nosecone:

No direct contact; isolated by the outer PET-CF shells, only a extension.

¶ Description

These form the load-bearing PET-CF structure and provide the housing and mechanical interface for the removable tip. Their internal geometry includes a cavity designed to lock the tip in place securely, by screwiwng it.

These shells are bonded to the inner wall of the carbon composite Nosecone by glue.

Inside a part, a screw is mechanically constrained by the shape of the hole that hosts the screw head, and then we secure the locking with blue epoxy glue.

¶ Main Specifications

| Specification | Value | Unit |

|---|---|---|

| Manufacturing | Impression 3D - Prusa Pro | — |

| Material | PET CF | — |

| Fastening | Collage | — |

¶ Interfaces

-

With Removable Tip: Screw ensure the tip is aligned and locked in place mechanically.

-

With Composite Nosecone: Bonded over a wide internal contact area using epoxy or equivalent adhesive.

No specific electrical or thermal interaction.

¶ Main description

You will find in this document all the information concerning this part.

¶ Interfaces

- With Nosecone Shell:

The coupler is glued inside the nosecone on the cylindrical section.

¶ Design Constraints

¶ Production Constraints

Mold Design:

- MDF female mold for vacuum infusion

- PET-CF male mold for prepreg layup

Nosecone Assembly:

- A flange interface is integrated along one edge to enable precise fitting of the molded parts

- Ensures structural continuity after final bonding

Dimensional Tolerances:

- A small margin on the cylindrical section ensures proper alignment and bonding reliability

Vacuum Infusion:

- Mold geometry and access points must support consistent resin flow and vacuum distribution

- Goal: minimize risk of voids and defects

¶ Operational Constraints

The nosecone has a structural role, primarily resisting external pressure loads.

Handling & Installation:

- No special safety precautions required

- Must be handled carefully to avoid deformation that could compromise function

Storage:

- Store in a dry, secure environment

- Do not place loads on the part to prevent distortion

Maintenance:

- No periodic inspections required

- Reusable as long as structural integrity is preserved

¶ Other Constraints

- Store under protective conditions to avoid damage or deformation

- No special transport requirements beyond impact and pressure protection

- Designed for reuse across multiple flights if in good condition

- Mechanical compatibility ensured through defined interfaces (flange, bonding zones)