¶ Introduction

¶ Purpose, Objective and Scope

The purpose of this document is to list the stages in the manufacture of Al-2195T84 - Al2050T84 tanks. It also includes lessons learned during the manufacturing process, as well as all the iterations that led to the final product.

¶ Context

After securing Constellium as a sponsor, we set our sights on manufacturing tanks from 2050T84 and 2195T84 aluminum, which are high-performance alloys. Using these alloys for the tanks would reduce their weight by 15 to 25% compared to tanks made from Al-6082T6. We began production of these tanks in June 2024, but due to numerous manufacturing issues, we have still not managed to produce a single unit (03.09.2025). Here you will find everything that has been done so far.

¶ Applicable and Reference Documents

- 2024_C_ST_PR_LLIM

- 2025_C_ST_TANKS_DDF

- 2025_C_ST_TANKS-6082T6_MAP

2024_C_ST_TANKS_PRESSURE-TSP

2024_C_ST_TANKS_PRESSURE_TR

2024_C_ST_TANKS_PRESSURE_TR-(BURST)

- 2024_C_ST_TANKS-2195_FEA

¶ Production Overview

¶ Raw Material

A sponsor will deliver 6 Al 2195 T84 plates of dimensions: 580[mm] x 743[mm] x 6.25[mm]. Those plates will then be transfered to the manufacturer, another sponsor.

For the end-caps, we will have Al 2050 T84 slabs with dimensions: 260[mm] x260[mm] x260[mm]. These aluminium slabs will be transfered to the EPFL Workshorps for further manufacturing.

We have more quantities of raw material because we might be needed to perform several manufacturing tests before having asatisfying result.

¶ Storage Location

| Check | Item | Qty | Location |

|---|---|---|---|

| Al 2195 T84 plates | 6 | DLL | |

| Al 2050 T84 slabs | 6 | DLL |

¶ Manufacturing locations

The machinging of the end-caps will be performed by various professional workshops at EPFL (such as ATME or ATMX) on CNC 5 axis milling machines.

The plates rolling and longitudinal welding will be perforned in one of our sponsor's facilities. Moreover, the final welding of the cylindrical section with its two corresponding end-caps will also be performed by our sponsor's weld specialists.

¶ Technical drawings

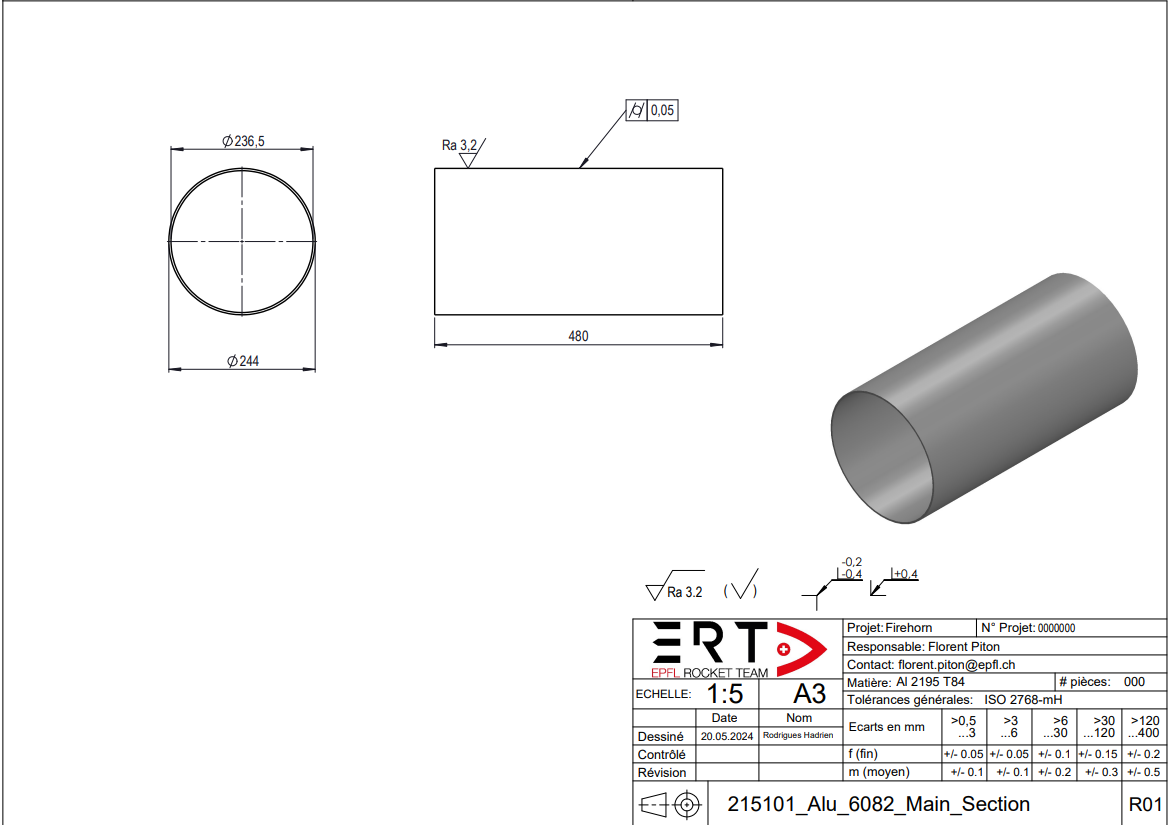

¶ 215101_Cylindrical_Section

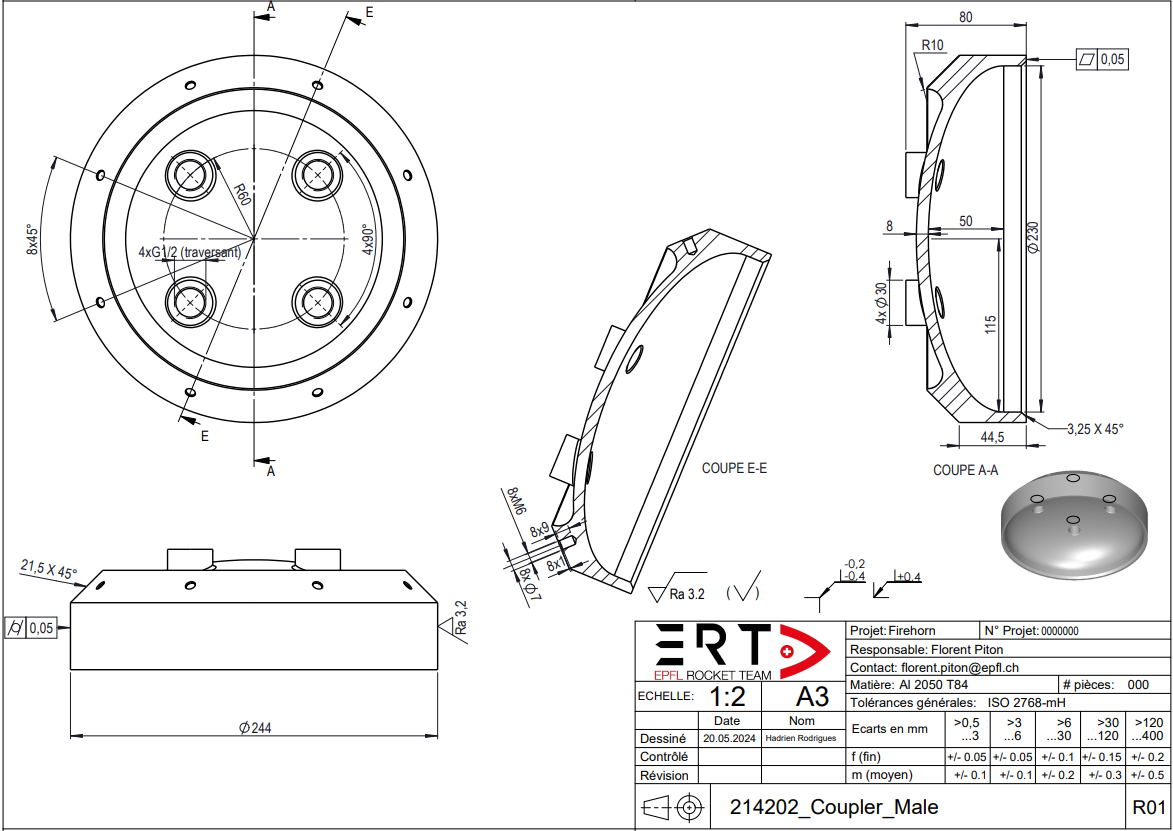

¶ 214202_Coupler_Male

¶ Manufacturing Procedure

| Check | Step | Description | Tool Ref | Part Ref | Image |

|---|---|---|---|---|---|

| 1) Plates rolling | The plates (2195 T84) will be rolled to the exact internal diameter 236.5[mm] | ||||

| 2) Caps blocks cutting | The caps raw slabs will be cut from the 2050 T84 plates with water jet cutting to 250[mm] of diameter and 80[mm] of height | ||||

| 3) Caps machining | The caps will be machined to their exact form at the CNC with a larger external diamater of 250[mm] | ||||

| 4) Caps welding to the cylinder | The caps will be welded to the main body with TIG using an aluminium alloy of the 4000 family | ||||

| 5) External diameter adjustment | The tank will be machinied with a lathe to get to the exact external diameter of 244 [mm] to flush with the external pannels of the rocket |

¶ Post Conditions

We need to ensure for the waterproofness of the tank's welds. Moreover, a pressure test at 90 [bar] will be performed.

| Check | Step | Description | Image |

|---|---|---|---|

| 1 | Ensure the waterproofness of the tank | ||

| 2 | Pressure test at 90 [bar] |